Introduction - The Lighting Revolution in Large Spaces

Imagine a sprawling distribution center at peak season. Workers are navigating narrow aisles under the faint, flickering light of aging metal halide fixtures. Shadows dance across high shelves, making it difficult to identify small-print SKU numbers, while the lingering heat from the lamps adds an unnecessary burden to the cooling system. This scenario is not just about poor visibility; it’s a critical business issue impacting accuracy, efficiency, worker safety, and the bottom line. For too long, illuminating vast spaces with ceilings over 15 feet has been a costly compromise. However, a profound shift is underway, driven by Light Emitting Diode (LED) technology.

LED high bay lights are the definitive solution engineered to conquer the unique challenges of industrial and commercial environments. This article serves as your comprehensive guide to this lighting revolution. We will move beyond the basic definition to explore the inner workings of these fixtures, articulate their undeniable economic and operational advantages, and map their diverse applications from warehouses to indoor farms. Most importantly, we will equip you with a strategic, step-by-step buyer’s guide to ensure your investment delivers optimal illumination, maximizes energy savings, and enhances safety for years to come. The future of large-space lighting is not only brighter but also smarter and more efficient.

Chapter 1: LED High Bay Lights Demystified - Beyond the Basic Definition

When we talk about illuminating large spaces, LED high bay lights undoubtedly stand out as a star modern lighting solution. But what exactly is an LED high bay light? Simply put, they are powerful, efficient lighting fixtures specifically designed for high-ceiling environments (typically over 15 feet or 4.5 meters, such as warehouses, gymnasiums, and factories). However, their true value extends far beyond this basic definition. To truly understand why they have become the industry standard, we need to delve into their working principles and core components.

At their core, they operate based on a phenomenon called “electroluminescence”. Unlike traditional lights that generate light by heating a filament (like incandescent bulbs) or exciting a gas (like metal halide lamps), LEDs (Light Emitting Diodes) emit light directly when an electrical current passes through a semiconductor material. This process is extremely efficient, as most of the energy is converted into light rather than heat. This allows LED high bay lights to produce more light using less electrical energy, while remaining cool to the touch, significantly reducing fire risks and cooling system loads.

However, not all LED high bay lights are created equal. Their performance, lifespan, and reliability are determined by four key components:

1. LED Chip: The Core of Quality

This is the light source itself. High-quality chips (often from renowned brands like Cree, Bridgelux, or Nichia) deliver higher, more stable luminous output with excellent lumen maintenance, ensuring the fixture remains bright throughout its lifespan. Inferior chips degrade quickly, leading to dimming.

2. Driver: The Heart of the System

The driver acts as the engine of the light. It converts incoming AC power to the low-voltage DC power required by the LEDs. A high-quality, constant-current driver is crucial for stability and longevity; a poor-quality driver is the most common cause of premature failure and can cause flickering.

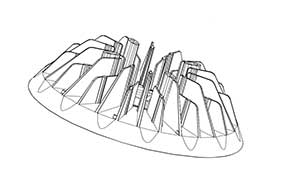

3. Heat Sink: The Key to Longevity

Although LEDs produce little heat themselves, the heat that is generated must be managed effectively. The heat sink, usually made of aluminum, functions to rapidly conduct and dissipate heat away from the LED chips. Superior thermal management significantly slows the degradation of the LEDs, directly determining whether the fixture can achieve its claimed 50,000 to even 100,000-hour lifespan.

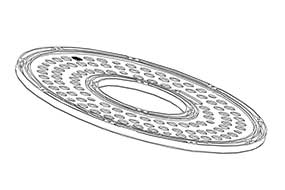

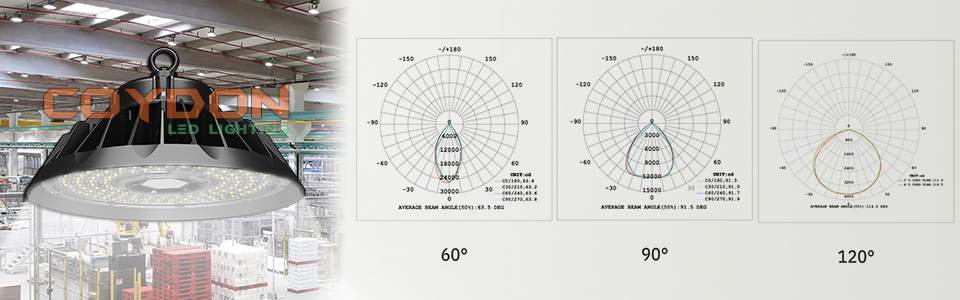

4. Optical Lens/Reflector: The Light Shaper

This component controls how light is distributed. Depending on the application (e.g., a wide open area requires a wide beam angle, while aisles between shelves may need a narrow beam angle to concentrate light), specific lenses or reflectors are used to shape the light beam, ensuring light is projected precisely and evenly where needed, avoiding glare and energy waste.

Therefore, an LED high bay light is far more than a simple “bulb”. It is a sophisticated system integrating precision electronics, advanced thermal management, and optical design. Understanding these intrinsic components is the first step toward making an informed choice, ensuring your investment delivers optimal performance and return.

Chapter 2: Why the Switch is Non-Negotiable - The Compelling Advantages

Continuing to rely on outdated lighting systems like Metal Halide (MH) or High-Pressure Sodium (HPS) in high-bay environments is no longer just an operational inefficiency; it’s a significant financial drain and a safety liability. The switch to LED High Bay Lights is not merely an upgrade-it’s a strategic transformation with undeniable, quantifiable benefits across economic, performance, and environmental fronts.

Economic Powerhouse: Saving Money from Day One

The most immediate and compelling advantage of LED High Bay Lights is their dramatic impact on the bottom line. This is achieved through two primary channels: exceptional energy efficiency and an extraordinarily long lifespan.

- Substantial Energy Savings: Traditional MH fixtures are notorious energy guzzlers. A significant portion of their energy consumption is wasted as heat rather than light. LED technology, by contrast, converts a much higher percentage of electricity directly into visible light. It’s common to replace a 400W Metal Halide fixture with a 120W-150W LED High Bay that delivers the same or even superior illumination. This translates to a reduction in energy consumption of 75% or more. For a facility operating hundreds of lights for 12-16 hours daily, this saving compounds into tens of thousands of dollars in annual electricity cost reduction. The return on investment (ROI) is often achieved in under two years, after which the savings go straight to the profit margin.

- Drastic Reduction in Maintenance Costs: The long lifespan of LEDs-typically ranging from 50,000 to over 100,000 hours – is a game-changer. A Metal Halide lamp may last 10,000-15,000 hours before burning out, necessitating frequent and costly replacements. In high-bay settings, each replacement involves renting expensive scissor lifts or cherry pickers and paying for skilled labor, not to mention the safety risks and production downtime. An LED fixture lasting 50,000 hours can operate for over a decade without needing a bulb change, effectively eliminating these recurrent maintenance expenses and the associated operational disruptions.

Superior Performance and Light Quality

Beyond cost savings, LEDs provide a qualitatively better lighting environment that enhances safety, accuracy, and comfort.

- Excellent Light Quality: High-quality LED High Bays offer a high Color Rendering Index (CRI), typically above 80. This means colors appear more vibrant and true-to-life compared to the often dull, yellowish, or greenish hue of HPS/MH lights. This is critical in applications like warehouses where accurate color identification of labels or parts is essential, in automotive repair shops for perfect color matching, and in retail spaces where product presentation matters.

- Instant On and Flicker-Free Operation: Metal Halide lamps require a several-minute warm-up period to reach full brightness and have a long restrike time if temporarily switched off. LEDs achieve full brightness instantly. Furthermore, they produce steady, flicker-free light, which reduces eye strain and fatigue for workers, leading to higher concentration levels and productivity. The elimination of flicker also makes them ideal for use with high-speed cameras and machinery, where stroboscopic effects from traditional lighting can create dangerous illusions of stationary motion.

Environmental and Safety Benefits

- Eco-Friendly: LED lights contain no mercury or other hazardous materials, making their disposal safer and less harmful to the environment compared to MH/HPS lamps. Their high efficiency also directly contributes to a lower carbon footprint by reducing power plant emissions.

- Reduced Heat Emission: LEDs operate at much lower temperatures than traditional lamps. This significantly reduces the radiant heat load on a space, which can lead to substantial savings on air conditioning costs, especially in warm climates. It also creates a more comfortable and safer working environment for employees.

| Feature | LED high bay lights | Metal Halide (MH) | Fluorescent High Bay |

| Average Lifespan | 50,000 – 100,000+ hours | 10,000 – 15,000 hours | 15,000 – 25,000 hours |

| Energy Efficiency | Excellent | Poor | Fair |

| Maintenance Cost | Very Low | Very High | Moderate |

| CRI (Color Rendering Index) | 80+ (High) | 65-70 (Low) | 70-85 (Fair to Good) |

| Start/Re-strike Time | Instant | 5-15 minutes | 1-30 seconds |

| Heat Output | Low | Very High | Moderate |

| Environmental Impact | No Mercury | Contains Mercury | Contains Mercury |

This clear advantage matrix underscores why the transition to LED is not a matter of “if” but “when”. The combination of direct cost savings, enhanced operational capabilities, and improved workplace conditions makes the switch an undeniable strategic imperative for any business operating in large-scale spaces.

Chapter 3: A Light for Every Need - Types and Form Factors

When upgrading the lighting in a high-ceiling space, selecting the right fixture type is as crucial as choosing the technology itself. While LED high bay lights share the core advantages of efficiency and longevity, their design and form factor directly impact light distribution, installation ease, and suitability for specific environments. For most industrial and commercial applications, the UFO High Bay stands out as the dominant and most versatile choice, but the future points toward even smarter, connected solutions.

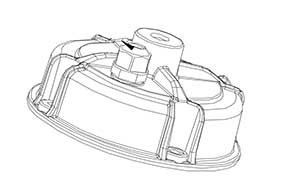

100 Watt

KD-HBD-W100-1

Ø248mm X 129mm

150 Watt

KD-HBD-W150-1

Ø295mm X 140mm

200 Watt / 240 Watt

KD-HBD-W200-1 / KD-HBD-W240-1

Ø320mm X 154mm

| Input Voltage: | AC 90V – 305V | |

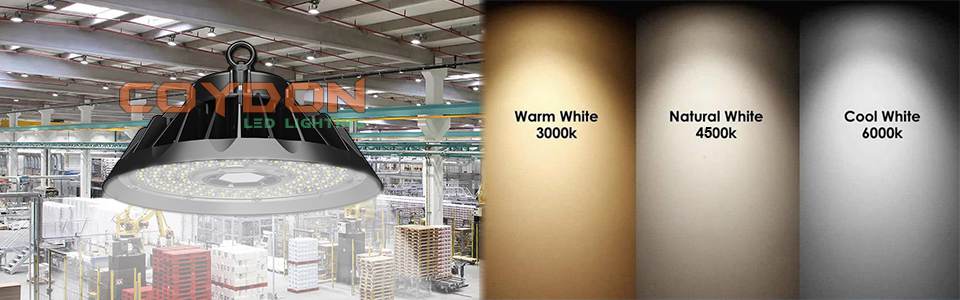

| Colour Temperature: | 3000K / 4500K / 6000K | |

| Color Rendering Index: | 80+ | |

| LED Type: | LED SMD 2835 ( OSRAM ) | |

| IP Grade: | IP65 | |

| Material: | Aluminium + PC Lens | |

| Luminous Efficiency: | 150 Lumens per watt | |

| Beam Angle: | 60° / 90° / 120° | |

| Warranty: | 5 Years | |

| Mounting Height: | 100 Watt: 15–20 ft (4.5–6 m) 150 Watt: 20–30 ft (6–9 m) 200 Watt: 30–40 ft (9–12 m) 240 Watt: 40–50 ft (12–15 m) |

UFO LED High Bay Lights: The Modern Industrial Workhorse

The UFO High Bay gets its name from its distinctive, sleek, and compact circular design that resembles an Unidentified Flying Object. This minimalist profile is far more than an aesthetic choice; the circular housing is often engineered to act as a large, integrated heat sink, promoting excellent thermal management which is critical for LED longevity. This design also makes the fixtures remarkably lightweight and easy to install, typically requiring only a single suspension point, which significantly reduces installation time and complexity.

In terms of performance characteristics, UFO High Bays are celebrated for their high efficiency and robust, uniform light output. They typically utilize high-quality LED chips paired with precision optical lenses (often polycarbonate or glass) to create a wide and consistent beam pattern. This effectively eliminates dark spots and harsh shadows on the floor below. This makes them the ideal solution for large, open areas with clear vertical space, such as warehouses, distribution centers, manufacturing assembly floors, and gymnasiums. In these settings, their broad and even illumination enhances safety for both personnel and machinery operations, directly boosting productivity.

Looking Ahead: The Dawn of Intelligent High Bays

Beyond the standard UFO design, the most significant innovation lies in the realm of Intelligent or Smart High Bay Lights. These are not mere illumination devices but sophisticated nodes on an Internet of Things (IoT) network. Built-in sensors enable features like motion detection, daylight harvesting, and energy consumption monitoring. They can be wirelessly controlled and grouped, allowing for customized lighting schedules, occupancy-based automation, and data collection for predictive maintenance. This transformative capability turns lighting infrastructure into a tool for unprecedented energy savings and operational intelligence, offering a glimpse into the future of smart facility management.

Chapter 4: Mapping the Applications - Where They Shine

LED high bay lights are not a one-size-fits-all solution; they are a versatile lighting technology engineered to meet the demanding requirements of vast, high-ceilinged environments. Their application extends far beyond simply illuminating a space; they are integral to enhancing safety, boosting productivity, and optimizing operational costs. Let’s explore the diverse landscapes where these powerful luminaires truly shine.

Industrial Powerhouses: Where Efficiency and Safety Reign

This is the native habitat of the high bay light. In settings like warehouses, distribution centers, and manufacturing plants, lighting is a critical component of daily operations. LED high bays provide bright, uniform, and shadow-free illumination across wide aisles and high storage racks. This ensures accurate reading of labels and inventory codes, speeding up picking and packing processes while drastically reducing errors. More importantly, the high-quality, flicker-free light minimizes eye strain for workers during long shifts and enhances overall safety by clearly illuminating potential hazards, moving equipment like forklifts, and emergency pathways. The significant reduction in heat output also contributes to a more comfortable working environment and lowers cooling costs.

Commercial and Retail Spaces: Enhancing Experience and Ambiance

The application of LED high bays has successfully expanded into large-scale commercial venues. In big-box retail stores, supermarkets, and sports arenas, lighting plays a dual role. It must provide sufficient brightness for customers to evaluate products comfortably and for staff to perform tasks efficiently. LED high bays, especially those with higher Color Rendering Index (CRI greater than 80), make colors appear more vibrant and true-to-life, which can enhance product appeal and influence purchasing decisions. In convention centers and exhibition halls, the ability to deliver consistent, glare-free light is crucial for creating a pleasant atmosphere for attendees. The modern, sleek designs of fixtures like Linear High Bays also contribute to the aesthetic appeal of these spaces.

Emerging and Specialized Applications: Pushing the Boundaries

The robustness and adaptability of LED technology have opened doors to highly specialized uses. In indoor farming and vertical agriculture, LED high bays are customized with specific light spectra (often red and blue wavelengths) to optimize photosynthesis and promote plant growth, revolutionizing year-round food production. Cold storage warehouses present an extreme challenge where conventional lights often fail due to low temperatures. Specially designed LED high bays not only withstand freezing conditions but also operate efficiently without the long warm-up times or performance degradation seen in traditional lighting, ensuring worker safety and product integrity. Similarly, in demanding environments like aircraft hangars and automotive repair shops, high-output, durable, and sometimes explosion-proof variants of high bays are essential for conducting detailed inspections and maintenance work safely.

In summary, from the hustle of a logistics hub to the controlled environment of a grow room, LED high bay lights have proven to be a transformative solution. They provide the precise quality and quantity of light required to turn challenging large spaces into safe, productive, and efficient environments.

Chapter 5: The Ultimate Buyer's Guide - A Step-by-Step Selection Process

Selecting the right LED high bay light is not about picking the brightest or the cheapest option. It’s a strategic decision that impacts your operational efficiency, safety, and bottom line for years to come. A well-considered choice will pay dividends, while a poor one can lead to inadequate lighting, wasted energy, and premature failure. This guide breaks down the selection process into three manageable steps, empowering you to make an informed decision tailored to your specific environment.

Step 1: Assess Your Space – The Foundation of Your Plan

Before looking at any product specifications, you must first thoroughly understand the space you need to illuminate. The physical characteristics of your facility will dictate the fundamental requirements for your lighting system.

Of course, please provide the length, width, and height of the installation space, as well as the mounting height (unit: meters) via email to CoydonLightingRobin@Gmail.Com. We will then provide an LED lighting simulation report, which will detail the number of fixtures required and include comprehensive 3D diagrams.

- Ceiling Height: This is the most critical factor. As a rule of thumb, fixtures designed for high bay applications are typically used in spaces with ceilings over 20 feet (6 meters). For heights between 12 and 20 feet (3.6 to 6 meters), you might consider low bay fixtures, which have a different light distribution pattern to prevent excessive glare at lower mounting heights. Confirm your exact height to narrow down your fixture type immediately.

- Layout and Obstructions: Is your space wide-open, like a warehouse distribution center or a gymnasium? Or is it filled with high shelving racks, machinery, or other obstacles? The layout determines the required beam angle.

- Wide Beam Angle (e.g., 120°): Ideal for open areas, providing uniform, widespread light coverage without dark spots between fixtures.

- Narrow Beam Angle (e.g., 60° or 90°): Essential for aisles between high shelving. They concentrate light downward onto the aisles and shelving surfaces, preventing light from being wasted on the tops of shelves or the upper ceiling area. This “task-oriented” approach is far more efficient.

- Wide Beam Angle (e.g., 120°): Ideal for open areas, providing uniform, widespread light coverage without dark spots between fixtures.

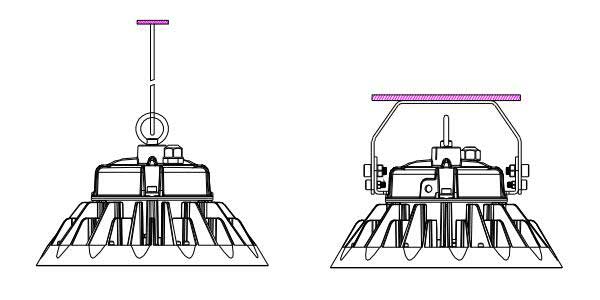

- Existing Infrastructure: Take note of your current electrical system and how the lights are mounted (e.g., pendant-mounted, chain-hung, or directly surface-mounted to a junction box). This will influence the ease of installation.

Step 2: Decipher the Technical Specifications – Speaking the Language of Light

Once you understand your space, you can dive into the technical details. Don’t be intimidated by the terms; they are your best tools for comparing apples to apples.

Lumens, Not Watts – Measuring Brightness Correctly: The era of choosing a light bulb based on watts (which measure power consumption) is over. With LEDs, you must look at lumens, which measure the actual amount of visible light produced.

- Calculating Your Needs: To determine how many lumens you need, you must first know the required illuminance level for your task, measured in foot-candles (FC) or lux (1 lux = 0.093 FC). Industry standards (like IES or OSHA) provide guidelines. For example, a warehouse storage area might require 10-20 FC (100-200 lux), while a detailed assembly area could need 50-100 FC (500-1000 lux). The formula is: Total Lumens = Area (in square feet) x Desired Foot-Candle Level. Then, divide this total by the number of fixtures to find the lumen output required per fixture. Higher ceilings require fixtures with higher lumen output to achieve the same foot-candle level on the floor or work plane.

- Please provide the length, width, height, and mounting height (in meters) of the installation space by email to CoydonLightingRobin@Gmail.Com. We will then provide an LED lighting solution and a simulation report, which will detail the required number of luminaires and include comprehensive 3D renderings.

Correlated Color Temperature (CCT) – Setting the Mood: CCT, measured in Kelvins (K), describes the apparent “warmth” or “coolness” of the light.

- 5000K – 6000K (Cool White / Daylight): This is the most common choice for industrial and commercial settings. It produces a bright, alert, and energetic atmosphere, ideal for enhancing concentration and productivity in workshops, warehouses, and sports facilities.

- 3500K – 4000K (Neutral White): Offers a crisper, yet less stark light than cooler temperatures. Excellent for retail environments, showrooms, and areas where visual comfort is a priority without being too warm.

- 2700K – 3000K (Warm White): Creates a cozy, inviting ambiance. Typically used in restaurants or hotel lobbies but less common in high-bay applications unless specific aesthetic goals are needed.

Color Rendering Index (CRI) – Seeing True Colors: CRI measures a light source’s ability to reveal the true colors of objects compared to a natural light source, on a scale of 0 to 100.

- The CRI is greater than 80: Suitable for most general industrial applications (storage, loading bays).

- The CRI is greater than 90: Essential for tasks requiring accurate color discrimination. This is critical in quality control areas, automotive paint shops, textile manufacturing, and high-end retail where correct color perception impacts product value and safety.

Step 3: Consider Additional Features – The Smart Upgrade

Modern LED high bays offer features that can deliver significant additional savings and operational control.

- Dimming Capabilities: Lights that can be dimmed allow for adaptive lighting. Pair them with sensors for even greater efficiency:

- Daylight Harvesting: Sensors detect the amount of natural light entering the space (e.g., through skylights) and automatically dim or turn off the LEDs nearby, saving energy.

- Occupancy/Vacancy Sensing: In areas with intermittent activity (e.g., storage aisles, restrooms), motion sensors can dim the lights to a low level (e.g., 20%) when vacant and bring them to full brightness when motion is detected.

- Daylight Harvesting: Sensors detect the amount of natural light entering the space (e.g., through skylights) and automatically dim or turn off the LEDs nearby, saving energy.

- Smart Controls and IoT Integration: This is the frontier of lighting technology. High bays can be equipped with wireless controls (like Zigbee or Bluetooth mesh) to form an intelligent network.

- Group Control and Scheduling: Control entire zones of lights from a central dashboard or smartphone app. Set schedules to ensure lights are only on when needed.

- Data Monitoring and Predictive Maintenance: Smart systems can monitor energy consumption, operating hours, and even driver health, sending alerts before a failure occurs. This transforms lighting from a cost center into a data-generating asset.

- Group Control and Scheduling: Control entire zones of lights from a central dashboard or smartphone app. Set schedules to ensure lights are only on when needed.

- Ingress Protection (IP) Rating: The IP rating (e.g., IP65, IP66) indicates the fixture’s protection against solid objects (like dust) and liquids. For environments that are dusty, humid, or require frequent wash-downs (e.g., food processing plants, cold storage), a high IP rating is non-negotiable to ensure longevity and safety.

Your Decision Flowchart

To bring it all together, follow this simple flowchart to guide your selection:

1.Start: What is your ceiling height?

- Greater than 20 ft (6 m): Proceed to High Bay fixtures.

- 12-20 ft (3.6-6 m): Consider Low Bay fixtures.

2.Next: What is the primary use of the space?

- Basic Storage/Logistics: Focus on cost-effective, standard-CRI (70+) fixtures with robust construction. Wide beam for open areas, narrow beam for aisles.

- Precision Work (Assembly, QC, Color-Sensitive): Prioritize High CRI (80+) and appropriate CCT (5000K recommended). Ensure excellent uniformity.

- Variable Occupancy (Warehouses with intermittent staff): Smart fixtures with occupancy sensors are highly recommended for maximum energy savings.

- Harsh Environments (Dust, Moisture, Cold): High IP Rating (IP65+) and specific temperature ratings are mandatory.

3.Final Check: Do you have a building management system or future plans for smart integration?

- Yes: Select dimmable fixtures with smart-ready drivers and wireless communication capabilities.

- No: You can opt for standard fixtures, but considering dimmable options leaves the door open for future upgrades.

By methodically working through these steps, you will move beyond confusion and be able to specify the perfect LED high bay lighting solution that meets your technical, operational, and financial needs.

Get your customized LED lighting solution by providing the length, width, height, and mounting height (Unit: meters). Click “Inquiry Now” to get started today!

Chapter 6: Installation and Maintenance - Ensuring Long-Term Performance

Proper installation and a simple yet consistent maintenance regimen are crucial to unlocking the full potential and promised lifespan of your LED high bay lights. Neglecting these aspects can lead to subpar illumination, reduced energy savings, and even premature failure.

Installation: The Foundation of Performance

The installation process sets the stage for decades of reliable service. While specific steps vary by fixture and building structure, key principles are universal. First, professional installation by a qualified electrician is highly recommended. They ensure compliance with local electrical codes and safe handling of high-voltage components.

Optimal spacing is critical to achieving uniform light distribution without dark spots or excessive glare. A common rule of thumb is to space the fixtures a distance equal to 1 to 1.5 times the mounting height (the distance from the floor to the light). For example, if lights are mounted at 20 feet, spacing them 20 to 30 feet apart is a good starting point, though this must be adjusted based on the fixture’s beam angle and the specific tasks in the space. Ensure mounting structures (e.g., conduit, J-hooks) are robust enough to support the fixture’s weight securely.

Furthermore, pay attention to wiring compatibility. Ensure the existing electrical infrastructure can handle the new LED system. While LEDs draw less current, it’s essential to verify voltage requirements and the integrity of connections to prevent issues like voltage drop over long wire runs.

Maintenance: Maximizing Lifespan and Efficiency

LED high bay lights are celebrated for their low maintenance, but they are not “install-and-forget” systems. A proactive approach ensures consistent performance. The primary maintenance task is regular cleaning. Dust and grime accumulation on the lens and heat sink can significantly reduce light output (lumen depreciation) and impede heat dissipation, which shortens the LED’s life. A simple wipe-down with a soft, dry cloth every 6 to 12 months, or more frequently in dusty environments, is sufficient. Always power off the lights before cleaning.

For systems with external drivers, periodically check the driver for any signs of damage or abnormal operation. Modern smart high bays offer a significant advantage here. Their built-in monitoring systems can provide early warnings for potential driver failure or performance degradation, enabling predictive maintenance before a complete outage occurs. This allows for scheduled replacements during off-hours, minimizing disruption.

By investing in correct installation and minimal upkeep, you protect your lighting investment, guaranteeing optimal safety, efficiency, and illumination for years to come.

Chapter 7: The Future is Bright and Connected - Trends in High Bay Lighting

The evolution of LED high bay lighting is far from over. The next frontier moves beyond simple illumination, transforming these fixtures into intelligent, connected nodes within a broader ecosystem. The future is bright, smart, and data-driven, offering unprecedented levels of control, efficiency, and functionality.

The most significant trend is the integration with the Internet of Things (IoT). Modern smart high bays are equipped with embedded sensors and wireless communication modules (like Zigbee or Bluetooth Mesh). This allows them to form a network where each light can be individually monitored and controlled. The benefits are profound. Facility managers can access real-time data on energy consumption, operational status, and even predict maintenance needs before a failure occurs, minimizing downtime. Furthermore, this sensor network can be leveraged for applications beyond lighting, such as asset tracking (using RFID or BLE tags), monitoring space utilization through occupancy heat maps, and enhancing security by detecting unusual movement patterns.

Another exciting development is Human-Centric Lighting (HCL). Research increasingly shows that light significantly impacts human well-being, circadian rhythms, and productivity. HCL systems in high bays can dynamically adjust the light’s colour temperature and intensity throughout the day to mimic the natural progression of sunlight – cool, bright white in the morning to boost alertness, shifting to warmer, softer tones in the afternoon to reduce eye strain and prepare for the end of the workday. This bio-adaptive approach can greatly improve employee comfort, morale, and performance in large industrial and commercial settings.

Sustainability remains a core driver. Future trends point towards enhancing the circular economy aspects of lighting. This includes designing fixtures for easier disassembly, using higher percentages of recycled materials, and enabling carbon footprint tracking through connected systems. Moreover, high bay lights are increasingly being designed to integrate seamlessly with on-site renewable energy sources, like solar panels, creating self-sustaining lighting solutions for warehouses and factories, further reducing their operational carbon emissions.

In conclusion, the high bay light of tomorrow is not just a source of light but a multifunctional data-generating asset that contributes to operational intelligence, human well-being, and corporate sustainability goals.

Conclusion: Ready to Transform Your Space?

You’ve seen the evidence. LED high bay lights offer unparalleled efficiency, slashing energy costs by up to 75% and eliminating frequent maintenance. They provide superior, safer light that boosts accuracy and worker well-being. The question is no longer if you should switch, but how soon you can start saving.

The answer is: right now. Translating this potential into real-world savings requires a plan tailored to your unique space. We make it easy. Click the “Inquire Now” button below to connect with our lighting experts. You’ll receive a personalized layout and a clear projection of your savings – with no obligation.

Stop researching and start saving. Act now and request your free quote today.