| Model: | Dimension: | Input Voltage: | Power: | CCT: | CRI: | LED Type: | IP Grade: | Material: | Luminous Efficiency: | Beam Angle: | Warranty: |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KD-HBD-W100-1 | Ø248mm X 129mm | AC 90V - 305V | 100 Watt | 3000K / 4500K / 6000K | 80 | LED SMD 2835 ( OSRAM ) | IP65 | Aluminium + PC Lens | 150 Lumens per watt | 60° / 90° / 120° | 5 Years |

| KD-HBD-W150-1 | Ø295mm X 140mm | AC 90V - 305V | 150 Watt | 3000K / 4500K / 6000K | 80 | LED SMD 2835 ( OSRAM ) | IP65 | Aluminium + PC Lens | 150 Lumens per watt | 60° / 90° / 120° | 5 Years |

| KD-HBD-W200-1 | Ø320mm X 154mm | AC 90V - 305V | 200 Watt | 3000K / 4500K / 6000K | 80 | LED SMD 2835 ( OSRAM ) | IP65 | Aluminium + PC Lens | 150 Lumens per watt | 60° / 90° / 120° | 5 Years |

| KD-HBD-W240-1 | Ø320mm X 154mm | AC 90V - 305V | 240 Watt | 3000K / 4500K / 6000K | 80 | LED SMD 2835 ( OSRAM ) | IP65 | Aluminium + PC Lens | 150 Lumens per watt | 60° / 90° / 120° | 5 Years |

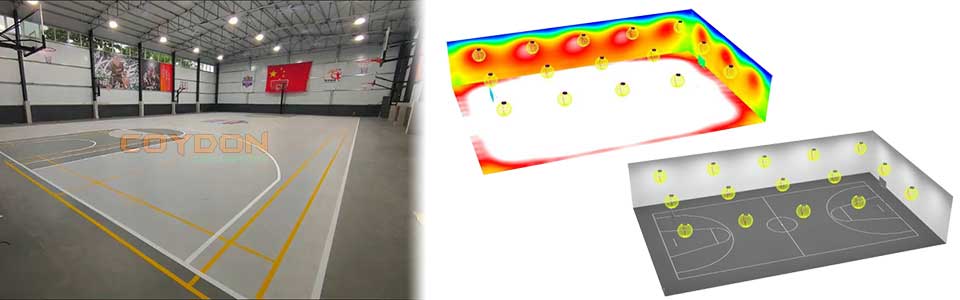

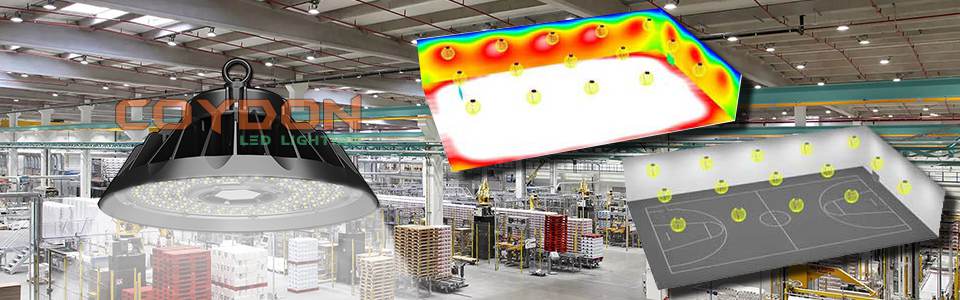

Project 01 ( In the indoor basketball court ):

Site size: 20 meters x 32 meters

Installation height: 6 meters

Products Used: 15 piece x 150 watt UFO LED high bay lights

Average illumination:

370 Lux ( Total area );

384 Lux ( basketball court );

The calculation report: UFO LED high bay lights 150 watt x 15 piece ( Project 01 )

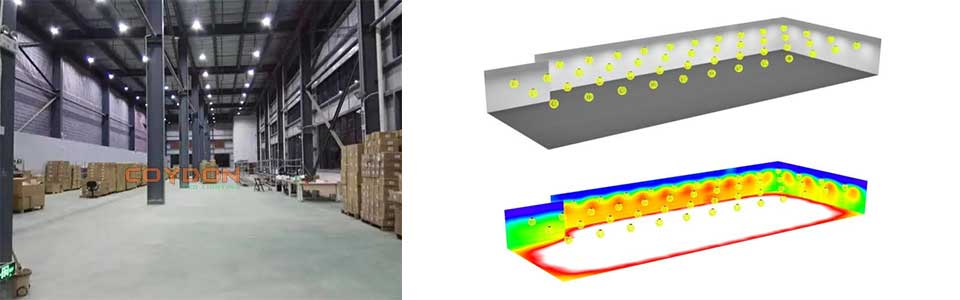

Project 02 ( In the warehouse ):

Site size: 30 meters x 80 meters

Installation height: 7 meters

Products Used: 46 piece x 150 watt UFO LED high bay lights

Average illumination: 338 Lux

The calculation report: UFO LED high bay lights 150 watt x 46 piece ( Project 02 )

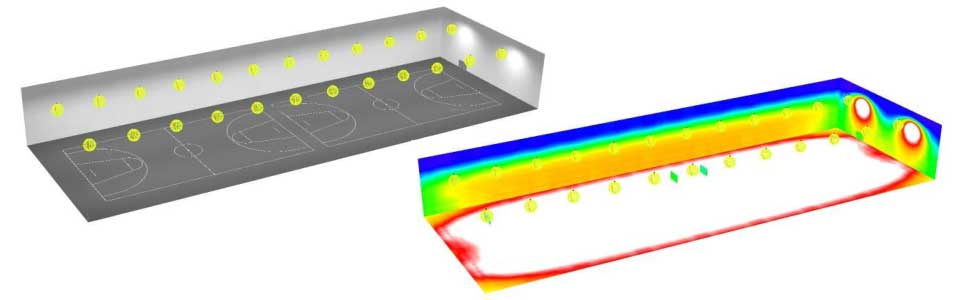

Project 03 ( In the indoor basketball court ):

Site size: 22 meters x 65 meters

Installation height: 7.5 meters

Products Used: 24 piece x 200 watt UFO LED high bay lights

Average illumination:

363 Lux ( Total area );

391 Lux ( basketball court 1 );

392 Lux ( basketball court 2 );

The calculation report: UFO LED high bay lights 200 watt x 24 piece ( Project 03 )

| Where can UFO LED high bay lights be used? | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

UFO LED high bay lights are the workshop of industrial, warehouse, commercial, public, sports and recreational facility lighting. Many issues affect the design and specification decisions for UFO LED high bay light, including hard-to-reach ceilings, wide open spaces, harsh operating conditions and long run times.

High headroom between floor and ceiling is a characteristic of manufacturing facilities, warehouses, distribution facilities, large retail stores, convention centers, exhibition halls, airport hangars, entertainment centers and stadiums. As utilitarian facilities, clear height specifications are of great importance.

Higher clear heights mean more cubic capacity to accommodate large and tall equipment in industrial buildings, more vertical storage space for stacking and racking in warehouses, more flexibility to support future operational and storage needs, and mission changes in multipurpose facilities.

However, with the increased height came other problems. Hard-to-reach ceilings, expansive spaces and long working hours challenged the lighting system to provide adequate lighting for safety, performance and productivity without excessive energy consumption and costly lighting maintenance.

What is a UFO LED high bay light?

Round high bay lights have evolved from the traditional style of luminaire, which features a cylindrical radiator, a top-mounted electrical box and a large aluminum reflector, to sleek, aesthetically pleasing low-profile luminaires. This type of luminaire is often referred to as UFO LED high bay lights simply because its shape looks like a disc.

UFO LED high bay lights were never designed to achieve just a sleek architectural look. It is the plate design of the LED modules that makes the low profile heat sink design necessary.

The disc-shaped heat sink provides a larger surface area to accommodate LED modules with large LES, facilitating a more even distribution of light. The maximized heat distribution area allows the waste heat generated by the LED array to diffuse quickly to the heat sink.

UFO LED high bay lights are composed of a luminaire assembly and a driver assembly. The heat sink is the most prominent part of the luminaire.

The heat sink also serves as the luminaire housing and is made of die-cast or cold-forged aluminum.

The LED module is an assembly of LEDs mounted on a metal core printed circuit board (MCPCB). An array of lenses is indexed to the board to regulate the luminous flux of the LEDs when it is necessary to control the beam dispersion.

The MCPCB functions both to provide electrical isolation and to propagate heat across the surface of the heat sink to which it is attached.

The fill density and pattern of the LEDs ensures optimal light distribution while keeping the high heat flux density below the saturation level of the PCB.

Control of the light distribution in high bay luminaires containing multiple SMD LEDs is typically achieved through lens arrays.

The ability to control the light emitted by the LEDs with a miniature composite lens allows high bay lighting to eliminate bulky aluminum reflectors. The LED driver is located in a separate aluminum housing or a thermally independent compartment.

The fill density and pattern of the LEDs ensures optimal light distribution while keeping the high heat flux density below the saturation level of the PCB. Control of the light distribution in high bay luminaires containing multiple SMD LEDs is typically achieved through lens arrays. Lens arrays consist of multiple optical control units that are mounted on each individual LED, regulating the luminous flux of each LED through critical vertical and horizontal planes.

Another benefit of the UFO LED high bay light design is that the compact form factor reduces packaging volume for easy transportation and storage.

The applications for UFO LED high bay light are very diverse. Almost all commercial, industrial, public, sports and entertainment facilities with high clearance between floor and ceiling require UFO LED high bay light to provide sufficient illumination.

Traditional lighting

Historically, high bay light has been the domain of luminaires using high intensity discharge (HID) light sources such as metal halide or high pressure sodium (HPS) lamps.

These bulb-based luminaires utilize circular reflectors to produce a rotationally symmetrical light distribution.

Although HID lamps have a significantly longer life and higher lumens than traditional incandescent lamps, HID lamps have some inherent characteristics that prevent them from meeting rapidly evolving codes and standards.

These lamps have high optical losses (typically around 30%), resulting in low luminaire performance, exhibit high lamp lumen depreciation (LLD), perform poorly in color reproduction, and have a limited color temperature range.

In addition to this, the high reload/maintenance frequency of HID luminaires, long start-up and hot restart processes, and potential ignition problems (due to housing failure) are of greater concern for those managing industrial, retail, warehouse and fitness facilities.

Of these light sources, metal halide is favored in overhead bridge applications because of its ability to operate at high wattages up to 1000 watts and its relatively high light source efficiency.

While low-wattage metal halide bulbs can last up to 20000 hours, the life expectancy of high-power bulbs typically decreases dramatically to a few thousand hours.

Poor start and restart performance, combined with restrictive dimming capabilities, make metal halide lamps obsolete in the age of digital lighting. While package failure (lamp explosion) is uncommon, it is a major safety concern because hot quartz from a broken lamp can ignite flammable gases or vapors, combustible dust, combustible fibers or flying objects that may be present in industrial environments.

Advantages of UFO LED high bay light

The unique physical characteristics and operating conditions of industrial, commercial and sports facilities make UFO LED high bay light different from other types of indoor luminaires.

By using lighting controls to operate UFO LED high bay light, there is still a tremendous opportunity to maximize energy savings.

The ability of light sources to interact with lighting controls and energy management systems has received increasing attention. A light source must have instant start/restart and dimming capabilities so that its light output can be controlled in a very dynamic manner in sync with digital or analog control signals.

Leaps and bounds of improvements in efficiency, performance and reliability have made LED lighting technology the logical choice for high bay lighting applications.

With light source efficiencies in excess of 150lm/W, the payback period of LED lighting systems is attractive enough to encourage conversion.

The energy savings of LED lighting go beyond light source efficiency improvements to provide unprecedentedly high lighting application efficiency (LAE) because more efficient light transmission can be achieved through optimal optical distribution and the use of advanced lighting controls.

A properly designed LED luminaire can last more than 5 years even in the harshest environments. With such a long service life, maintenance-free operation further increases the total cost of ownership.

At the same time, improved lighting uniformity, flicker-free illumination, enhanced color rendering and customizable spectral composition of light contribute to optimal visual conditions that can significantly improve task performance and personnel safety in the work environment.

Compared to HID lighting fixtures, which take a long time to reach full brightness and often fail prematurely under frequent switching operations, the instant control of a wide range of intensities and robustness to high frequency switching make LED lighting systems perfect for implementing complex, adaptive lighting solutions.

Optical design

In some applications a high bay light with exposed LEDs will do the lighting job well, but in some applications a precision designed secondary optical element is required to regulate the luminous flux of the light source and provide uniform illumination to a specified target area.

Once the standard optical element for HID and conventional style LED high bay light, aluminium reflectors have seen a gradual decline in use.

In modern LED systems, the use of reflectors is very limited and their role is simply to block the direct line of sight to the LED, reduce glare and shield spill light.

Modern LED high bay lights are often designed with a light module that has an array of LEDs distributed over a large circuit board. A large parabolic reflector will control only the light incident on the reflector surface, with a large proportion of the LED’s emitted light not interacting with the reflector.

UFO LED high bay lights are often equipped with an array of integral injection moulded lenses to control light with a precision previously unattainable with bulky reflectors.

LED lens arrays can be custom moulded to fit snugly over the LED and use single or multiple optical elements to extract and control almost all of the light produced by the light source.

This type of optical element combines refraction and reflection to maximise beam shaping capabilities and minimise optical loss.

The precision formed lens arrays allow the beam produced by each LED to radiate out at any desired beam angle for directional illumination of vertical surfaces.

LED lens arrays are manufactured from PMMA (acrylic), which is economically sensible and has superior optical properties.

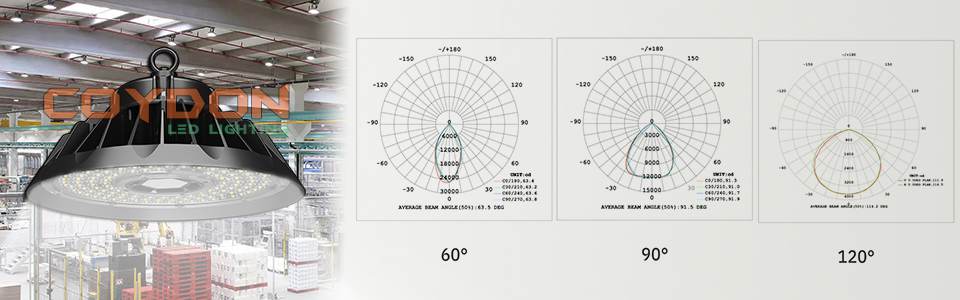

Beam angle of UFO LED high bay light have 60° / 90° / 120°.

Thermal Management

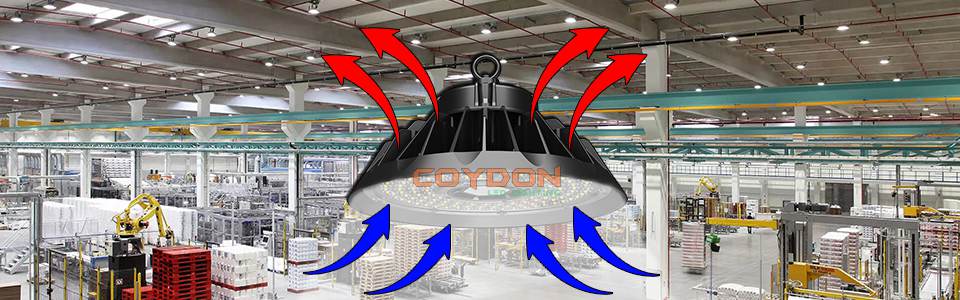

Thermal management is an important issue for the sustainability of systems with UFO LED high bay lights, as these systems typically operate at high power densities and generate considerable heat that, if allowed to accumulate, will raise operating temperatures.

The UFO shape design allows the heat generated by the LED package to be transferred to the surrounding environment through the shortest possible thermal path. The heat transfer path of UFO LED high bay lights starts at the semiconductor junction of the LED, passes through the MCPCB and heat sink, and finally reaches the ambient air.

Achieving a robust thermal path in systems with UFO LED high bay lights requires higher reliability, high operating temperature capable solder joints or electrical interconnections between the LED package and the PCB.

The dielectric layer of a multilayer PCB should be thin enough to ensure good heat transfer from the LED while also providing sufficient electrical insulation between the circuit and the aluminum cladding.

Thermal interface material (TIM) is often used to completely fill the interface air gap between the circuit board and the heat sink, thus minimizing the interface contact resistance.

Heat sinks for UFO LED high bay lights are typically constructed of die-cast aluminum. The die-casting process provides the opportunity for cost-effective heat sink manufacturing and offers the ability to design flexible three-dimensional geometries to maximize convective surface area.

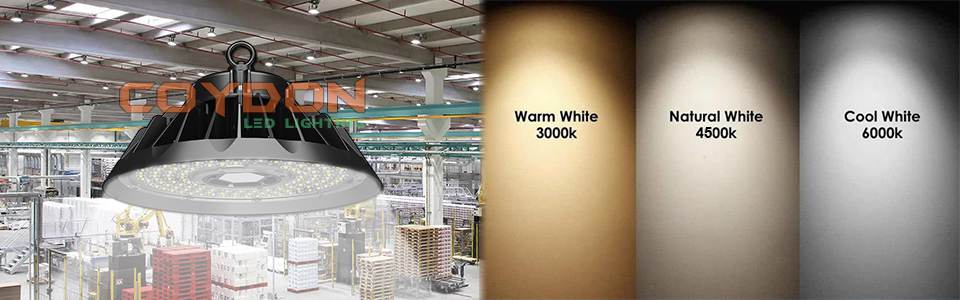

Color temperature and Color rendering index (CRI)

Color rendering index (CRI) refers to the light source on the object to restore the sunlight to the human visual perception of the ability of the high or low. The higher the color rendering, the closer the CRI value is to 100, the stronger the color reproduction ability of the object, the easier it is for the human eye to distinguish the color of the object.

Color temperature is a unit of measurement that indicates the color component contained in light.

Theoretically, blackbody temperature refers to the color presented by an absolute black body after it has been heated from absolute zero (-273°C). When heated, a blackbody gradually changes from black to red, turns yellow, glows white, and finally emits blue light.

When heated to a certain temperature, the spectral composition of the light emitted by the black body, it is called the color temperature at this temperature, the unit of measurement is “K” (Kelvin).

The luminous efficacy of LEDs is also traded off in terms of color characteristics. Warm colors and high color rendering index (CRI) are associated with low LED luminous efficacy because of Stokes loss and the eye’s sensitivity to long wavelength light.

UFO LED high bay lights typically have a correlated color temperature (CCT) greater than 4000K.

Color rendering is a general expression of a light source’s ability to faithfully reproduce the color of an object. As expected, for industrial and commercial lighting, cost and efficiency are often at odds with the color quality of the light source.

The decision about the color rendering of the light source is balanced with the luminous efficacy of the light source. Typically, the color rendering of UFO LED high bay lights is between 70 and 80.

The color temperature have three type do you chooce, they are 3000K, 4500K, 6000K, and CRI is 80.

Illuminance uniformity

The purpose of the UFO LED high bay light is to provide essentially uniform illumination throughout the area. Uniform horizontal illumination is important for task visibility, material handling and general circulation.

Most industrial, retail and Class III sports facilities require an average uniformity ratio of 3:1 or less. A high bay luminaire that provides very uniform light distribution will contribute significantly to good visual conditions and wide luminaire spacing.

The illumination uniformity of UFO LED high bay light can be improved by laying the LEDs at optimal spacing on a large circuit board and evenly distributing the light emitted by the LEDs through a precision-designed composite lens.

Ingress Protection

Where economically feasible, the LED optics of UFO LED high bay lights should be sealed with a high IP rating, such as IP65 or above, to prevent the ingress of moisture and contaminants, such as dust, dirt and other particles.

The optical system also provides mechanical protection for the LEDs and plays an important role in the entrance protection (IP) of the luminaire. In wet locations, high humidity or dusty environments, the optical lens is sealed to the housing with a continuous silicone pad.

High IP rated luminaires may come with an integral membrane vent which balances the internal/external air pressure to relieve sealing pressure while blocking water and contaminants.