Stop Wasting Energy and Money: Are Your High Bay Lights Holding Your Business Back?

Picture this: In a vast warehouse, up to 60% of the lighting electricity bill is essentially wasted – not because lights are left on, but because those outdated, inefficient traditional high bay lights, like Metal Halide lamps, convert a significant portion of energy into useless heat rather than light illuminating your workspace.

Furthermore, dim or uneven lighting can lead to a 15% increase in picking errors, impacting not only operational efficiency but also creating safety hazards. In today’s highly competitive industrial landscape, lighting is far more than just about “seeing”; it’s directly tied to worker safety, operational accuracy, overall productivity, and ultimately, your bottom line.

Industrial lighting is a critical infrastructure investment. Making the wrong choice means you continue to bear high electricity bills, frequent maintenance costs, and potential production losses. A smart decision, however, can deliver significant energy savings, a safer work environment, and more efficient operations.

This article will reveal the Ten Key Features you must consider when choosing a modern industrial lighting solution. These features are crucial benchmarks for determining whether a high bay light is truly efficient, reliable, and economical.

We will clearly explain why each feature matters and how it directly impacts your operational costs and efficiency. Simultaneously, we will highlight how the new generation of lighting technology, exemplified by UFO LED High Bay Lights, sets the industry standard across these core dimensions, offering you an ultimate, comprehensive solution.

It’s time to stop paying the hidden costs for outdated lighting technology. Read on to discover how a single, smart upgrade can transform your lighting system from a constant drain into a strategic asset that drives your business forward.

Top 10 Features to Consider When Selecting LED High Bay Lights

1. Lumens, Not Watts: The True Measure of Lighting Efficiency

For decades, we’ve been conditioned to think that “wattage equals brightness”. But this is a myth left over from the incandescent era.

With modern LED lighting, especially for industrial high bays, the true measure of light output is Lumens, and the key metric for efficiency is Luminous Efficacy (lm/W).

Watts simply measure energy consumption. Lumens measure the actual amount of visible light produced.

Therefore, Luminous Efficacy (Lumens per Watt or lm/W) is the crucial number – it tells you how much light you get for every unit of electricity you pay for. A higher lm/W rating means more light for less power, directly slashing your energy bills.

For high-bay applications, achieving the right light levels on the floor or work surface is critical for safety and productivity. The required lumens depend heavily on your ceiling height. Here is a general guideline:

| Mounting Height | Recommended Minimum Lumens |

|---|---|

| 6 – 8 meters (20 – 26 ft) | 15,000 – 25,000 lm |

| 8 – 10 meters (26 – 33 ft) | 25,000 – 35,000 lm |

| 10 – 12 meters (33 – 39 ft) | 35,000 – 50,000 lm |

Traditional Metal Halide (MH) fixtures typically struggle to achieve even 100 lm/W, meaning a significant portion of your electricity bill is wasted as heat, not light.

This is where modern UFO LED High Bay Lights revolutionize efficiency. Our models, like the KD-HBD series, deliver an exceptional efficacy of 150 lm/W.

This means they produce 150 lumens of brilliant, uniform light for every single watt of power consumed. Compared to a 100W MH fixture (producing roughly 8,000 lumens), our 100W UFO LED High Bay produces a staggering 15,000 lumens – brighter light for the same wattage, or the same light for a fraction of the cost.

By focusing on lumens and efficacy, you make a direct investment in lower operational costs. Switching to high-efficacy UFO LED high bays is one of the fastest and most effective ways to reduce your facility’s energy consumption and carbon footprint.

2. Beating the Heat: How Advanced Thermal Management Defines Lifespan

In the world of LED high bay lights, heat is the silent killer, the primary culprit behind performance degradation and premature lifespan reduction.

LED chips generate significant heat while emitting light. If this heat is not dissipated promptly and effectively, it leads to a rise in the junction temperature of the chip, subsequently causing severe lumen depreciation – a gradual dimming of the light output over time.

Worse, prolonged operation at high temperatures drastically shortens the electronic lifespan of both the LEDs and the driver, rendering the promised tens of thousands of hours ineffective in real-world applications.

Therefore, superior thermal management is not an optional luxury but the fundamental cornerstone that ensures LED fixtures deliver on their promise of ultra-long service life.

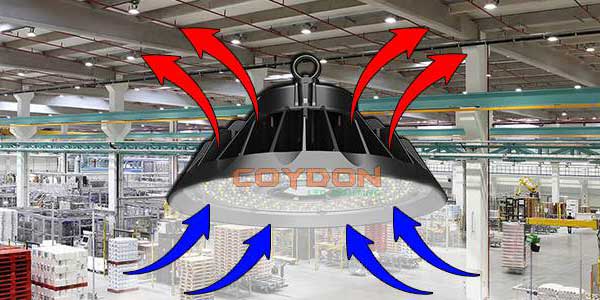

Evaluating a fixture’s cooling capability hinges on the design of its heat dissipation path and the thermal conductivity of the materials used. High-quality UFO LED high bay lights typically employ a die-cast aluminum housing integrated with meticulously designed aluminum heat sink fins.

Aluminum possesses excellent thermal conductivity, rapidly drawing heat away from the LED chips to the entire housing. The extensive surface area of the fins significantly increases contact with the ambient air, acting like a “respiratory system” for the light, facilitating more efficient heat dissipation through natural convection.

The unique, compact circular structure of UFO high bay lights offers an inherent geometric advantage for thermal management. Compared to traditional linear fixtures or products with complex structures, its symmetrical circular design allows heat to radiate evenly from the center outwards, preventing the formation of localized hot spots and ensuring a more uniform temperature distribution across the entire cooling surface, thus maximizing heat dissipation efficiency.

This efficient thermal management translates directly into performance stability and extended lifespan. It effectively curbs lumen depreciation, ensuring the fixture maintains high lumen output even after thousands of hours of operation.

This is precisely why our UFO high bay lights can confidently offer an exceptional service life exceeding 50,000 hours, significantly reducing the total cost of ownership associated with frequent replacements and maintenance, allowing your investment to shine brightly and reliably for years to come.

3. Precision Lighting: Choosing the Right Beam Angle to Eliminate Dark Spots

In industrial lighting, being “bright enough” is not sufficient. How light is distributed often matters more than the total lumen output in determining practical effectiveness and energy efficiency. The Beam Angle is a critical specification that directly dictates the coverage area and uniformity of the light.

Simply put, the beam angle describes the conical angle at which light is emitted from the fixture. A Narrow Beam Angle (e.g., 60° or 90°) concentrates light into a smaller area, creating a more intense central hot spot and longer throw distance.

This is ideal for high-bay environments (e.g., over 12 meters/40 feet) or for focusing light in narrow aisles and between racks. It ensures light is precisely “placed” on the task surface without excessive spill onto useless aisles or walls, thereby preventing energy waste.

Conversely, a Wide Beam Angle (e.g., 120° or larger) provides broader flood lighting, ensuring even illumination across large areas without sharp cut-offs.

This is crucial for open areas with moderate ceiling heights (e.g., 6-10 meters / 20-33 feet), such as manufacturing floors, gymnasiums, or picking areas in retail distribution centers. It effectively reduces shadows and dark spots, enhancing overall visual comfort and safety.

Our UFO High Bay Lights excel in this aspect due to their exceptional flexibility. A key advantage is their capability to be equipped with various optional secondary optical lenses. This means you can select the most appropriate beam angle lens tailored to your specific application – be it the dense rack aisles of a high-stack warehouse or the vast expanse of an assembly hall.

Through this precision light distribution design, we ensure every lumen is put to work, directly illuminating the areas that need it. This achieves a high-quality lighting solution characterized by no dark zones, minimal glare, and maximized energy savings, significantly boosting operational efficiency and reducing running costs.

4. Built to Last: IP Ratings and Durability for Demanding Environments

In industrial settings like warehouses, manufacturing plants, and food processing facilities, lighting fixtures face relentless challenges – dust, moisture, chemical exposure, and high-pressure washdowns.

An ordinary light might fail quickly under these conditions, leading to frequent replacements, safety hazards, and operational downtime. This is where the IP (Ingress Protection) rating becomes a critical specification, acting as your first line of defense.

The IP code, such as IP65, clearly defines a fixture’s resilience. The first digit (6) signifies complete protection against dust ingress. The second digit (5) confirms protection against low-pressure water jets from any direction.

For even harsher environments with powerful cleaning systems, an IP66 rating (protection against strong water jets) is recommended.

UFO High Bay Lights are engineered to master these challenges. They typically feature a robust die-cast aluminum housing. This material is not only highly durable but also excellent for heat dissipation. Combined with a tightly sealed, high-quality polycarbonate (PC) or tempered glass lens, this construction effortlessly achieves IP65 or higher ratings.

This means dust cannot interfere with sensitive electronic components, and moisture from humidity or cleaning will not penetrate the fixture. Choosing a UFO High Bay Light with a high IP rating is a direct investment in uninterrupted operation, significantly reduced maintenance costs, and long-term reliability, ensuring your lighting system is truly built to last in the most demanding environments.

5. Beyond Brightness: How Color Temperature and CRI Boost Productivity and Safety

When selecting industrial lighting, many focus solely on brightness (lumens), but two other critical factors – Color Temperature (CCT) and Color Rendering Index (CRI) – are equally vital for creating a productive and safe work environment. Understanding and optimizing these can significantly impact operational efficiency.

Color Temperature (CCT) measures the hue of the light, ranging from warm yellow (low Kelvin, e.g., 3000K) to cool blue (high Kelvin, e.g., 5700K).

In industrial settings like warehouses and manufacturing plants, a cooler CCT around 5000K is highly recommended. This mimics natural daylight, which helps reduce eye strain, enhances alertness, and improves overall visibility – key factors in minimizing errors and accidents during detailed tasks or long shifts.

Color Rendering Index (CRI), on the other hand, indicates how accurately a light source reveals the true colors of objects compared to natural light.

It is scored from 0 to 100. A higher CRI means better color discrimination. For industrial applications, a CRI above 80 is essential. It ensures that workers can accurately distinguish labels, wiring, safety signs, and product details, reducing misidentification and enhancing both safety and workflow precision.

Our UFO LED High Bay Lights are engineered to meet these exacting standards. With customizable CCT options, including the recommended 5000K, and a CRI consistently exceeding 80, they deliver high-quality illumination that promotes visual comfort and accuracy.

This not only boosts productivity by reducing fatigue and errors but also creates a safer, more reliable working environment. Don’t just light up your space – optimize it with lighting that cares for both people and performance.

6. Smart Savings: Unlocking Additional 30% Efficiency with Dimming and Sensors

In the pursuit of ultimate energy efficiency in industrial lighting, relying solely on high-efficiency light sources is no longer enough. The real potential for savings lies in intelligent control – particularly microwave sensor dimming technology.

This allows your UFO high bay lights to automatically reduce brightness in unoccupied or inactive areas, preventing energy waste. Statistics show that properly deploying smart sensing and dimming systems can easily achieve up to an additional 30% in energy savings. For warehouses or workshops operating 24/7, this translates to significantly lower electricity bills.

Compared to traditional infrared sensors, microwave sensors offer stronger penetration and a wider detection range, capable of accurately detecting subtle movements and even sensing presence through obstacles.

When an area is vacant, the lights can automatically dim to a lower level (e.g., 30% power), instantly returning to full brightness when personnel or vehicles enter. This “lighting-on-demand” approach not only saves power but also extends the luminaire’s lifespan.

Choosing UFO high bay lights that are compatible with microwave sensors and 0-10V/DALI dimming is a crucial step in building a smart infrastructure for your factory. Our UFO series supports modular intelligent controls, allowing for easy integration of sensing and dimming modules without the need to replace the entire system, offering flexible upgrades at a manageable cost.

Stop letting your lights run at full power continuously – embrace smart controls to create an efficient, adaptive, and future-ready lighting environment.

7. Plug-and-Play Simplicity: Why Easy Installation and Maintenance Matter

When calculating the true cost of industrial lighting, the initial purchase price is just the beginning.

The real expenses often lie in the complex installation process and the inevitable, costly maintenance downtime. This is where the design philosophy of UFO LED High Bay Lights truly shines, transforming potential headaches into remarkable savings and operational ease.

Installation is the first hurdle. Traditional lighting systems can be cumbersome, requiring multiple mounting points and complicated wiring. UFO High Bay Lights, with their signature single-point suspension design (via hook, chain, or conduit), drastically simplify this process.

A single worker can often handle the mounting and connection, significantly reducing labor time and installation costs. This “plug-and-play” approach means your new, energy-efficient lighting system is up and running faster, minimizing disruption to your daily operations.

However, the most significant long-term benefit comes from revolutionary maintenance simplicity. Unlike integrated fixtures where a single component failure spells a complete unit replacement, premium UFO High Bay Lights feature a modular design. Key components like the LED driver – the most common part to potentially fail – are often user-replaceable in the field without needing special tools.

Imagine a scenario: instead of renting a scissor lift, paying for labor, and replacing an entire fixture at a high cost, your maintenance staff can simply and safely swap out a driver from ground level in minutes. This modularity slashes maintenance costs, reduces spare part inventory, and, most importantly, keeps your facility brightly lit with minimal downtime.

By combining effortless installation with service-friendly modularity, UFO LED High Bay Lights deliver a powerful one-two punch against high Total Cost of Ownership, ensuring your investment pays dividends for years in convenience and savings.

8. IK Ratings: The Hidden Spec That Protects Your Lighting Investment from Impact

In demanding industrial environments like warehouses, manufacturing plants, and sports halls, lighting fixtures are frequently exposed to physical impacts – whether from forklifts, falling tools, or even sports equipment.

These incidents can lead not only to fixture damage but also to costly downtime, safety hazards, and frequent replacements. This is where the often-overlooked IK rating becomes critical.

The IK code (from IK00 to IK10) measures a fixture’s resistance to mechanical impact.

For most industrial settings, a minimum rating of IK08 is recommended – capable of withstanding an impact of 5 joules, equivalent to a 1.7 kg weight dropped from 0.3 meters. In high-risk zones such as loading bays or near heavy machinery, IK10 protection (20 joules of impact resistance) is essential to ensure long-term reliability.

UFO high bay lights excel in this area. Thanks to their robust die-cast aluminum housing and durable tempered glass or polycarbonate lenses, these fixtures typically achieve up to IK10 ratings – far surpassing the protection offered by conventional linear lighting. This makes them the ideal choice for harsh industrial applications where impact resistance is non-negotiable.

Don’t let hidden risks compromise your operations. Choose UFO high bay lights with high IK ratings to protect your investment and maintain uninterrupted performance.

9. Versatile Power: Wide Voltage Input and Surge Protection for Uninterrupted Operation

In complex industrial environments, a stable power supply is not always a given.

Grid fluctuations, voltage instability, and even instantaneous current surges can be invisible killers for lighting systems, leading to reduced performance, premature failure, and even production downtime. Therefore, selecting luminaires with superior electrical performance is crucial, primarily reflected in wide voltage input and robust built-in surge protection capabilities.

Wide voltage input is a core advantage of modern, high-quality UFO High Bay Lights. This feature allows the same luminaire model to adapt to varying grid standards across different regions and buildings, significantly simplifying procurement, inventory management, and installation processes.

There’s no need to stock multiple models for different voltage requirements, reducing the risk of installation errors or returns due to voltage mismatch. This enables true plug-and-play functionality and enhances project deployment flexibility.

However, merely adapting to a voltage range is not sufficient. Protection against transient overvoltages or current surges potentially present in industrial grids is equally important. This is where built-in surge protection proves its value.

High-quality UFO High Bay Lights integrate efficient surge protection circuits, capable of withstanding instantaneous impacts of several kilovolts or higher. This effectively shields the internal LED light source and precision driver from damage.

This additional layer of protection acts like “body armor” for the fixture, significantly enhancing its reliability and lifespan in harsh electrical environments, and minimizing maintenance costs and downtime caused by luminaire failure.

Wide voltage compatibility combined with robust surge protection forms the electrical foundation for the stable operation of UFO High Bay Lights.

They are no longer optional premium features but standard configurations for demanding industrial applications, safeguarding your return on investment and ensuring your lighting system operates continuously and efficiently under any power condition.

10. Peace of Mind: What a Strong Warranty and Support System Really Means

When investing in high-performance lighting like UFO LED high bays, a robust warranty and responsive manufacturer support aren’t just fine print – they are your ultimate assurance of quality, reliability, and long-term operational peace of mind. A substantial warranty period,

such as the 5-year coverage offered with our KD-HBD series, is far more than a marketing promise; it is a direct reflection of the manufacturer’s confidence in the product’s durability and performance under demanding industrial conditions.

This commitment means that every component – from the advanced thermal management system to the high-efficacy LEDs and robust IP65-rated housing – has been engineered to last, minimizing the risk of premature failure and unexpected downtime.

Beyond the warranty itself, accessible and knowledgeable technical support is crucial. In fast-paced industrial environments, every minute of downtime translates to lost productivity and revenue.

Choosing a supplier that offers localized, responsive support ensures that any issues – whether related to installation, compatibility, or performance – are resolved swiftly and effectively.

This proactive approach to customer care not only protects your initial investment but also enhances your total cost of ownership by reducing maintenance hassles and extending the luminaire’s operational life.

Ultimately, a strong warranty and support system build an essential bridge of trust between you and the manufacturer.

It signals a partnership dedicated to your success, ensuring that your transition to advanced UFO LED high bay lighting is seamless, sustainable, and secure for years to come.

When evaluating options, prioritize suppliers who stand firmly behind their products – because true value lies not just in the light you see today, but in the unwavering reliability you can count on tomorrow.

Make the Smart Switch to UFO LED High Bay Lights Today

In today’s competitive industrial landscape, lighting is far more than just visibility – it’s a critical factor impacting your operational costs, employee safety, and overall productivity.

As detailed through the ten key features, UFO LED High Bay Lights demonstrate exceptional performance:

- an outstanding efficacy of 150 lm/W ensures no energy is wasted;

- advanced thermal management guarantees long life and consistent output;

- precision optics direct light exactly where it’s needed;

- robust IP65 rating and high IK impact resistance withstand harsh environments;

- superior color temperature and high CRI enhance visual clarity and comfort;

- smart dimming compatibility paves the way for future savings;

- easy installation and modular maintenance significantly reduce the total cost of ownership;

- wide voltage input and built-in surge protection ensure reliable operation;

- finally, a strong 5-year warranty secures your investment.

These ten advantages do not work in isolation but synergize to create a comprehensive lighting solution that is efficient, reliable, economical, and future-proof.

Choosing UFO LED High Bay Lights means addressing all core concerns – energy efficiency, maintenance, light quality, and long-term ROI – in one strategic move towards sustainable operation and cost control.

Take Action Now and Embark on Your Efficient Lighting Journey!

- Get a Free Professional Service: Contact us now for a customized lighting layout design and a precise ROI calculation.

- Explore Our Product Range: Browse our complete series of UFO High Bay Lights to find the perfect model for your specifications.

- Deepen Your Knowledge: Download our Industrial Lighting White Paper to gain in-depth industry insights and best practices.

Don’t let outdated lighting continue to drain your profits. Make the smart switch today!