Introduction: The Pillars of Industrial LED Performance

Industrial lighting operates in a world of extremes. Facilities face relentless challenges: abrasive dust, pervasive moisture, mechanical vibrations, and severe thermal swings. In these unforgiving environments, lighting is a critical infrastructure component. The correct choice directly dictates plant safety, operational efficiency, and total cost of ownership. Standard fixtures frequently prove inadequate, succumbing to premature failure and performance decay.

The Coydon Lighting KD series stands apart. Engineered for endurance, the FLN/FLM LED floodlights and HBD UFO LED high bay lights deliver sustained, high-performance illumination. Their resilience is no accident. It is the direct result of a meticulously engineered partnership between two core elements: a superior aluminum structure and a high-performance polycarbonate lens. This synergy forms the foundation of their robust design.

This article delves into the engineering excellence of the KD series. We will examine how the strategic integration of materials and design translates into tangible benefits for the most demanding industrial applications. From unparalleled heat dissipation to impact-resistant optics, we uncover the pillars of professional-grade lighting.

1. The Critical Role of Material Science in Industrial Lighting

1.1. The Limitations of Conventional Fixtures in Demanding Environments

Industrial environments present unique lighting challenges that traditional technologies struggle to meet. Halogen and metal halide lamps, while once considered standard, now reveal multiple critical shortcomings in modern industrial applications. Their most apparent limitation lies in energy efficiency – these fixtures consume excessive electricity while delivering comparatively poor illumination output. The operational costs accumulate rapidly in facilities requiring extensive lighting coverage.

The thermal performance of conventional lighting poses another serious concern. These fixtures convert significant portions of electrical input into waste heat rather than usable light. This inefficient energy conversion not only represents wasted electricity but also creates operational challenges. The excessive heat accelerates component degradation, particularly affecting light output quality and fixture longevity. Lumen depreciation occurs at an accelerated pace, requiring more frequent replacements.

Physical durability presents yet another limitation. Glass enclosures, common in traditional fixtures, prove highly susceptible to breakage from accidental impacts or thermal stress. In busy industrial settings where tools and equipment are constantly in motion, this fragility translates to legitimate safety concerns and maintenance headaches. The risk of glass shattering necessitates immediate cleanup and replacement, potentially disrupting workflow.

Color rendering quality further compounds these issues. With typically low CRI ratings, traditional fixtures distort color perception in the workspace. This visual inaccuracy can impact numerous industrial processes where color differentiation matters – from quality control inspections to safety sign recognition. Workers may struggle to identify subtle color variations in materials or detect potential hazards under such lighting conditions.

The cumulative effect of these limitations results in unexpectedly high total cost of ownership. Beyond the obvious energy waste, facilities face recurring expenses for bulb replacements, maintenance labor, and production interruptions. When accounting for all these factors, the initially cheaper traditional fixtures often prove more expensive over their operational lifespan compared to modern alternatives.

1.2. Why Aluminum and Polycarbonate? An Introduction to Superior Materials

Contemporary LED technology overcomes traditional limitations through strategic material selection, with aluminum and polycarbonate emerging as the definitive choices for industrial applications. Aluminum stands out primarily for its exceptional thermal management capabilities. The metal’s innate thermal conductivity allows it to function as an integrated heat sink, efficiently drawing heat away from sensitive LED components. This proactive thermal control maintains optimal operating temperatures, directly contributing to extended lifespan and consistent performance.

Beyond thermal advantages, aluminum offers remarkable structural benefits. Its natural corrosion resistance makes it ideally suited for challenging industrial environments where moisture, chemicals, or temperature fluctuations are common. When enhanced through anodization, this corrosion resistance becomes even more pronounced. The material’s inherent strength provides reliable protection for internal electronics while maintaining relatively lightweight construction, simplifying installation processes.

Polycarbonate brings complementary advantages that address optical and safety requirements. Its impact resistance dramatically outperforms traditional glass, virtually eliminating concerns about broken lenses in industrial settings. This durability ensures long-term reliability even in environments where accidental impacts may occur. The material’s optical properties allow precise engineering of light distribution patterns, enabling manufacturers to create lenses that eliminate glare and ensure even illumination.

The optical stability of polycarbonate represents another significant advantage. Unlike some plastics that yellow or degrade when exposed to UV radiation, high-quality PC maintains its clarity throughout the fixture’s lifespan. This ensures consistent light quality and color transmission over years of operation. Furthermore, polycarbonate’s flexibility in manufacturing allows for custom optical designs tailored to specific application needs.

The combination of aluminum and polycarbonate creates a comprehensive protection system. Together, they form robust environmental seals that achieve high IP ratings, safeguarding internal components from dust, moisture, and other contaminants. This material synergy represents the current gold standard in industrial lighting design, delivering unmatched performance, safety, and reliability across diverse operating conditions while optimizing long-term cost efficiency.

2. A Deep Dive into the Aluminum Structure of KD Fixtures

2.1. The Integral Heat Sink: Mastering Thermal Management

LED performance directly correlates with thermal management effectiveness. Junction temperature critically determines both operational lifespan and light output quality. The KD series addresses this fundamental requirement through sophisticated aluminum engineering. Each fixture operates as a comprehensive thermal management system. The aluminum housing serves as the primary heat dissipation mechanism, efficiently transferring thermal energy.

Modern extrusion technology enables precisely engineered thermal designs. Manufacturers implement specialized fin configurations during the production process. These intricate fin structures dramatically increase the total available surface area. Enhanced surface exposure significantly improves heat transfer efficiency to surrounding air. Natural convection currents flow optimally between the strategically spaced fins.

This continuous thermal removal process ensures stable operation. Our KD-HBD UFO LED high bay light models demonstrate exceptional thermal performance characteristics. Their construction incorporates meticulously arranged cooling fins working in harmony with substantial aluminum mass. This synergistic approach maintains ideal operating temperatures even under demanding conditions.

The KD-FLN LED floodlight series employs equally advanced thermal strategies. Their extended profiles feature comprehensive finning patterns spanning the entire fixture length. This intelligent design guarantees uniform heat distribution across all sections, preventing localized thermal buildup and ensuring consistent performance.

Thermal Performance Advantages

Maintaining thermal consistency delivers numerous operational benefits. It preserves rated lumen output throughout the product lifespan. It ensures color temperature remains stable over extended periods. It guarantees consistent color rendering performance from installation onward. Most significantly, it extends operational lifespan well beyond conventional standards.

The aluminum extrusion process permits exacting thermal control. Engineering teams design complex internal channels that optimize heat conduction from LED boards. These channels simultaneously enhance overall structural integrity while facilitating efficient thermal transfer. Aluminum’s inherent thermal conductivity makes it the perfect material for high-performance LED applications.

Heat dissipates rapidly throughout the aluminum structure, moving systematically from warmer regions to cooler sections. This balanced distribution eliminates dangerous hot spots that compromise LED performance. The extensive surface area then radiates accumulated heat effectively into the environment, completing this sophisticated two-stage thermal management process.

2.2. Engineered for Resilience: Durability and Corrosion Resistance

Industrial environments demand extraordinary durability from lighting fixtures. The KD series meets these challenges through strategic material selection and advanced engineering. High-grade aluminum alloys provide exceptional structural strength, reliably withstanding physical impacts and persistent vibrational stresses. This robust protection extends comprehensively to sensitive internal electronic components.

Corrosion resistance receives equally meticulous engineering attention. Numerous industrial settings contain aggressively corrosive elements including high humidity, chemical vapors, and extreme temperature variations. Standard materials deteriorate rapidly under such conditions, but our solution involves comprehensive surface treatment protocols.

The aluminum undergoes specialized anodization processing that creates a thick, durable protective oxide layer. This coating bonds permanently at the molecular level with the base metal, delivering superior resistance to environmental degradation while enhancing overall aesthetic appeal.

Advanced Protection Systems

The anodized layer provides multiple protective advantages simultaneously. It effectively prevents oxidation and chemical corrosion while resisting scratching and abrasion damage. This comprehensive protection maintains optimal performance in the most challenging conditions, ensuring long-term operational reliability.

The material demonstrates remarkable resilience across diverse industrial environments including manufacturing facilities, warehouse complexes, chemical processing plants, and outdoor installations. The housing maintains structural integrity despite prolonged exposure to harsh conditions, significantly reducing maintenance requirements and associated costs.

2.3. Form Follows Function: Design Flexibility and Ease of Installation

Aluminum extrusion technology provides exceptional design flexibility that the KD series fully leverages. Integrated features streamline installation processes while enhancing performance. Mounting systems form seamlessly with main profiles, eliminating unnecessary assembly steps and potential failure points.

Cable management receives thorough engineering consideration. Dedicated conduit entries and wire channels are extruded directly into the housing, organizing electrical connections neatly and safely while contributing to achieving superior IP protection ratings.

The lens retention system exemplifies precision engineering with specially designed grooves that securely hold lenses while maintaining proper gasket compression. This ensures consistent environmental protection throughout the product’s operational lifespan.

Installation Efficiency Benefits

Weight optimization delivers significant practical advantages. Aluminum’s excellent strength-to-weight ratio enables robust yet lightweight construction that simplifies handling during installation while reducing structural support requirements.

The integrated design philosophy substantially reduces installation time through perfectly aligned mounting brackets, streamlined electrical connections, and minimal adjustment requirements. These factors collectively lower labor costs while ensuring reliable long-term performance.

Enhanced Thermal Engineering

The thermal management system incorporates additional sophisticated features. Thermally conductive pads interface between LED boards and aluminum housing, maximizing heat transfer efficiency. Computational fluid dynamics informed the fin design, optimizing airflow patterns for natural convection cooling.

The aluminum alloy composition was specifically formulated for thermal applications, containing trace elements that enhance heat dissipation capabilities. This material science innovation allows the KD series to maintain higher light output for longer durations compared to conventional designs.

3. The Polycarbonate Lens: Clarity, Protection and Control

3.1. Unbreakable Defense: Impact Resistance and Environmental Sealing

Polycarbonate lenses provide superior impact resistance. They significantly outperform traditional acrylic and glass alternatives. This durability proves crucial in demanding industrial environments. Accidental impacts from tools or equipment occur frequently. PC lenses withstand such events without cracking or shattering.

The material’s inherent strength ensures long-term reliability. It maintains structural integrity despite physical stress. This eliminates safety concerns associated with broken glass. It also reduces maintenance costs and replacement needs. Facilities avoid frequent lens replacements.

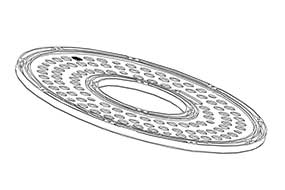

Environmental protection represents another critical advantage. The lenses form perfect seals with aluminum housings. This sealing is essential for achieving high IP ratings. Our KD-HBD UFO LED high bay lights achieve IP65 protection. The KD-FLN/FLM LED floodlights reach even higher IP66 standards.

These ratings guarantee complete dust prevention. They also protect against powerful water jets. Facilities can safely perform high-pressure cleaning. The lighting continues operating reliably throughout. This combination of impact and environmental resistance makes PC lenses ideal for industrial applications.

3.2. Precision Optics: Tailoring Light Distribution for Industrial Applications

Beam angle selection is fundamental to lighting efficacy. The KD series offers a comprehensive range of options for both LED floodlights and UFO LED high bay lights. Understanding these differences is key to optimal design.

Narrow Beam Angles (10°, 15°, 25°, 60°)

These concentrate light for long throw and precise application.

- LED Floodlights (10°, 15°, 25°): Ideal for long-distance projection and wall washing, creating uniform illumination on vertical surfaces.

- UFO LED high bay lights (60°): This is a classic narrow beam for high-bay applications. It is perfect for warehouses with very high ceilings (typically 10-15 meters), providing focused light onto narrow aisles and high-density storage racks, minimizing light spill into aisles.

Medium/Wide Beam Angles (90°, 120°)

These provide broad, uniform illumination for general area lighting.

- LED Floodlights (90°): Optimal for wide coverage in areas like logistics centers and parking lots.

- UFO LED high bay lights (90°, 120°): The most versatile choices for industrial high bays.

- 90°: A standard beam for ceilings 6-10 meters high, offering a good balance of intensity and spread for general manufacturing areas.

- 120°: An ultra-wide beam for lower ceilings (4-8 meters) or applications requiring extremely even light distribution with minimal shadows, such as assembly lines or packaging areas.

Asymmetric Beam Angles (65 x 25°, 130 x 30°)

These specialized beams create rectangular light patterns.

- LED Floodlights (65 x 25°, 130 x 30°): Engineered specifically for wall washing, efficiently distributing light evenly across vertical surfaces with minimal waste.

Optical Control Technology

Polycarbonate enables this precision through micro-prisms, frosted, or clear finishes. This technology eliminates glare, ensures light goes exactly where needed, and maximizes efficiency for every application.

4. The Coydon Lighting KD Series: A Synthesis of Performance and Value

4.1. Engineered Excellence: KD-HBD UFO LED High Bay Lights and KD-FLN/M LED Flood Lights

The Coydon Lighting KD series represents the pinnacle of industrial lighting innovation. These fixtures combine advanced engineering with practical application needs. The KD-HBD UFO LED high bay light delivers exceptional 150 lumens-per-watt performance. This outstanding efficiency is housed in a compact, durable UFO-shaped design. The fixture is specifically engineered for high-bay industrial environments.

Intelligent features enhance its energy-saving capabilities. Built-in microwave motion detection automatically adjusts lighting based on occupancy. The 1-10V dimming capability allows precise light level control. These smart functions optimize energy usage throughout operation. They provide additional savings beyond the already impressive efficiency.

The KD-FLN/M LED Flood Light series offers remarkable application flexibility. Multiple wattage options cater to various illumination requirements. Comprehensive beam angle selections ensure perfect light distribution. These lights serve diverse outdoor and industrial applications effectively. They provide reliable performance in demanding conditions.

The replacement specifications demonstrate superior efficiency. A 200W KD-HBD UFO LED high bay light replaces 400W metal halide fixtures. A 150W KD-FLN LED Flood Light substitutes 1000W halogen units. This substantial power reduction delivers immediate operational savings. The energy conservation translates directly to lower electricity costs.

4.2. Quantifiable Benefits: Energy Savings, Longevity, and Reduced TCO

The KD series delivers measurable financial advantages through multiple channels. Energy consumption reduction provides the most immediate benefit. Facilities typically achieve 50-70% power savings compared to traditional lighting. This substantial decrease directly lowers monthly electricity expenses. The cost reduction positively impacts operational budgets significantly.

Long-term value is guaranteed through exceptional product longevity. The robust construction ensures reliable performance over extended periods. The advanced thermal management system prevents premature degradation. This results in a operational lifespan exceeding 50,000 hours. The extended duration minimizes replacement frequency and associated costs.

The comprehensive 5-year warranty provides additional security. It covers manufacturing defects and performance issues. This protection reduces potential maintenance expenses substantially. Facilities benefit from predictable operating costs throughout the warranty period. The assurance supports long-term budgeting and financial planning.

Total Cost of Ownership analysis reveals the true economic advantage. While initial investment may be higher, long-term savings are substantial. The combination of reduced energy consumption and minimal maintenance creates significant value. Most projects achieve complete return on investment within 18-24 months. Subsequent years deliver pure operational savings and financial benefits.

4.3. Beyond the Product: Professional Support and Services

Coydon Lighting provides comprehensive solutions beyond quality products. Our professional services ensure optimal project outcomes from start to finish. We begin with thorough application analysis and technical consultation. Our experts evaluate specific requirements and environmental conditions. This detailed assessment guarantees perfect product selection and configuration.

We offer advanced Dialux lighting simulation reports for all major projects. These detailed computer analyses predict performance with remarkable accuracy. They visualize lighting distribution patterns before installation. The simulations verify illuminance levels and uniformity metrics. This proactive approach eliminates uncertainty and ensures perfect results.

Our technical team provides continuous support throughout project implementation. We assist with installation planning and product configuration. Technical guidance ensures optimal performance from commissioning onward. This comprehensive support continues throughout the product lifecycle. Our commitment extends long after the initial purchase.

We help clients achieve certification compliance for various standards. Our products meet international quality and safety requirements. The documentation facilitates smooth project approval processes. This additional service saves valuable time and resources. It ensures projects proceed without unnecessary delays or complications.

5. Your Partner in Professional Industrial Lighting

The Coydon Lighting KD series represents the culmination of intelligent design and engineering excellence. Through its advanced aluminum construction and precision polycarbonate lenses, this product line delivers unmatched performance that translates directly into operational benefits. The synergy between robust thermal management and superior optical control ensures exceptional reliability in the most demanding industrial environments.

Our fixtures are engineered to provide long-term value through energy efficiency and durability. The significant reduction in power consumption directly lowers operational costs. The extended product lifespan minimizes maintenance requirements and replacement expenses. These combined advantages result in a substantially improved total cost of ownership that benefits your bottom line.

Coydon Lighting stands as your dedicated partner in industrial illumination. We combine premium products with comprehensive technical support. Our team of lighting specialists possesses deep industry knowledge and application expertise. We understand the unique challenges faced by different industrial sectors. This insight allows us to provide tailored solutions for your specific requirements.

Take the Next Step Toward Optimal Lighting

Ready to transform your facility’s lighting and achieve substantial savings? Click the ‘Inquiry Now’ button to connect with our lighting specialists today. Share your project details and requirements with our team. We will provide customized product recommendations tailored to your space. You will receive a competitive quotation that reflects your specific needs.

We also prepare comprehensive Dialux simulation reports for your project. These detailed visualizations demonstrate lighting performance before installation. They ensure the proposed solution meets all your operational criteria. Let’s work together to build a brighter, more efficient future for your facility. Contact us today to begin your lighting transformation journey.

Conclusion: The Definitive Choice for Demanding Environments

In industrial lighting, superior performance is engineered from the ground up. The fundamental truth remains: materials and structural design ultimately determine performance ceilings. Through meticulous engineering, the Coydon Lighting KD series transforms this principle into tangible excellence. Its precision-crafted aluminum housing and resilient polycarbonate lens work in perfect synergy.

This combination delivers more than just illumination; it establishes a new standard for reliability. These fixtures are engineered to withstand the most challenging conditions while maintaining optimal efficiency. They represent not merely lighting tools, but durable industrial assets that provide long-term value. The proven performance and robust construction make the KD series the unequivocally intelligent choice. It is the definitive solution for professionals who prioritize quality, efficiency, and lasting performance in their projects.