Introduction: The Silent Revolution in Industrial Lighting

Have you ever stepped into a modern warehouse or factory and noticed those saucer-shaped lights suspended from the high ceilings? Their unique, UFO-like appearance is unmistakable. But have you ever wondered, why this specific shape? The answer lies at the heart of a silent revolution in industrial lighting.

For decades, spaces like these were dominated by the harsh, energy-intensive glow of Metal Halide lamps. The shift to LED technology was more than a simple bulb swap; it was a fundamental change in design philosophy. While everyone celebrates LEDs for their energy savings, the true challenge has always been managing the intense heat they generate within their compact bodies. This is where mere component upgrades fall short, and intelligent design takes center stage.

At Coydon Lighting, the iconic UFO form is not a stylistic gimmick. It is a form-follows-function masterpiece, meticulously engineered to tackle LED technology’s greatest adversary: heat. This sophisticated thermal management system is the unsung hero that directly dictates a fixture’s long-term lumen maintenance, operational lifespan, and ultimately, your Total Cost of Ownership. It is the crucial difference between a short-lived product and a long-term investment.

We are committed to moving beyond basic illumination. Through innovative engineering, we deliver optimal lighting solutions where performance, reliability, and efficiency truly matter. The UFO shape is our promise of superior design, built to endure.

1. The Critical Challenge - Taming the Heat in LED High Bay Lights

1.1. The Hidden Enemy: Junction Temperature

LEDs are famously called “cold light” sources because their light isn’t generated by heating a filament like incandescent bulbs. However, this label creates a dangerous misunderstanding. While the light itself may feel cool, LEDs actually generate significant heat at their core. This heat concentrates in a microscopic area: the semiconductor junction within the LED chip.

The temperature at this precise point, known as the “junction temperature,” represents the most critical parameter determining LED health and performance. When junction temperatures rise beyond safe limits, they trigger a devastating cascade of effects. Lumen output diminishes rapidly through accelerated lumen depreciation. The light’s color consistency suffers, shifting toward unpleasant blue or yellow tones that distort visual perception. Most critically, for every sustained 10°C increase beyond the rated temperature, the LED’s operational lifespan can be cut in half according to industry standards. In extreme scenarios, prolonged overheating leads to immediate, catastrophic failure. Multiple industry studies, including analyses in technical literature, confirm that inadequate heat dissipation remains the primary reason inexpensive LED fixtures fail prematurely, often before delivering any meaningful return on investment.

1.2. The Real Cost: Beyond Bulb Burnouts

The true consequences of poor thermal management extend far beyond the simple burnout of a single fixture. They create a domino effect of operational and financial burdens that impact entire facilities. Maintenance expenses represent the most visible cost, with fixture replacements in high-bay environments requiring specialized lifting equipment, certified technicians, and production downtime that disrupts workflow. Simultaneously, energy consumption increases progressively as overheating LEDs lose efficiency, forcing them to draw more power while producing diminishing light output.

These technical failures translate directly into safety hazards throughout the facility. Gradual lumen depreciation creates dark zones and uneven illumination that increase risks for workers operating machinery or navigating busy aisles. The cumulative financial impact transforms what initially appeared to be a cost-saving investment into a recurring expense nightmare, with damaged operational budgets and compromised workplace safety. The hidden costs of poor thermal design inevitably surpass any initial savings from cheaper fixtures.

1.3. The Design Failure: Inadequate Thermal Solutions

Why do conventional lighting solutions consistently fail to address this fundamental challenge? The answer lies in fundamentally inadequate thermal design approaches. Traditional fixtures relying on simple metal housings or minimally sized aluminum heat sinks prove completely insufficient for modern high-power LED applications. These outdated designs lack both the necessary surface area for effective heat dissipation and the sophisticated thermal pathway engineering required to rapidly draw heat away from sensitive electronic components.

As LED power densities continue increasing, the thermal management challenge intensifies accordingly. Basic metal enclosures that sufficed for traditional lighting technologies become overwhelmed when confronted with the concentrated heat generation of high-lumen LED arrays. Without purpose-engineered cooling solutions, these conventional designs essentially trap heat against the very components they should protect, creating a thermal bottleneck that systematically degrades performance and shortens operational life. The limitations become apparent through visible performance degradation within surprisingly short timeframes, demonstrating that advanced thermal management isn’t an optional enhancement but an essential requirement for professional-grade LED lighting systems.

2. Deconstructing the UFO - A Masterclass in Engineering Design

2.1. The Aerodynamic Heat Sink: More Than Just Fins

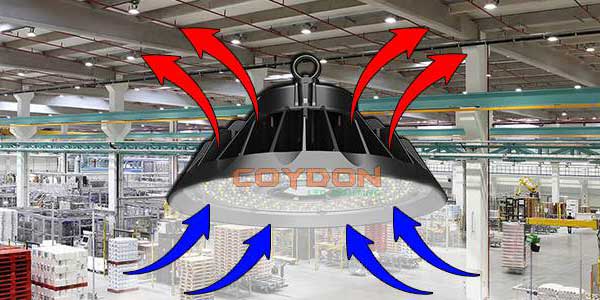

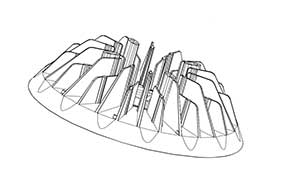

The distinctive UFO shape of Coydon Lighting’s LED High Bay lights represents a perfect fusion of form and thermal engineering. The entire fixture body functions as a massive, integrated heat sink meticulously crafted from die-cast aluminum. This fundamental design principle transforms the complete structure into a highly efficient, active thermal management system rather than just a protective cover.

The iconic saucer-like form is scientifically engineered to maximize surface area for optimal heat dissipation. Concentric, precision-molded fin-like rings adorn both the top and bottom surfaces, creating an extensive landscape for effective heat exchange with the surrounding air. This specific geometry serves a crucial aerodynamic purpose by systematically disrupting stagnant boundary layers of air. It actively promotes continuous convective airflow across the entire fixture surface, enabling heat to transfer efficiently from the aluminum body into the atmosphere. The advanced die-cast manufacturing process creates a seamless, monolithic structure that eliminates thermal interface resistance common in multi-part assemblies. This ensures an unobstructed thermal pathway for heat to travel directly from high-temperature LED chips to the expansive external cooling fins, maintaining optimal junction temperatures and ensuring maximum LED performance and longevity.

2.2. Material Matters: The Role of High-Grade Aluminum

Material selection proves absolutely fundamental to achieving superior thermal performance in LED lighting systems. Aluminum consistently emerges as the premier choice for high-performance heat sinks due to its exceptional combination of physical and thermal properties. The metal’s outstanding thermal conductivity enables rapid heat absorption and distribution throughout the entire structure, effectively preventing dangerous localized hot spots that can degrade LED chips. This characteristic proves particularly crucial for maintaining color consistency and maximizing lumen output over the fixture’s operational lifetime.

Beyond its thermal advantages, aluminum provides significant practical benefits for high-bay installations. Its remarkable strength-to-weight ratio minimizes structural stress on ceiling supports while simplifying handling during installation. The material’s inherent corrosion resistance ensures long-term reliability even in challenging industrial environments containing moisture or chemical vapors. Coydon Lighting specifically utilizes high-grade aluminum alloys that guarantee consistent material purity and optimal thermal conduction properties. This unwavering commitment to material excellence, clearly reflected in our product specifications, forms the essential foundation supporting our entire thermal management philosophy. It enables the sophisticated UFO design to deliver sustained cooling performance throughout decades of continuous operation.

2.3. Passive Cooling Superiority: The Key to Maintenance-Free Operation

Coydon Lighting’s UFO LED high bay lights exemplify the engineering superiority of advanced passive cooling systems. These luminaires achieve exceptional thermal performance through intelligent design alone, completely eliminating dependence on active cooling components like internal fans. This fundamental approach delivers truly maintenance-free operation that industrial users require. The passive system guarantees completely silent performance while consuming zero additional energy for thermal management, creating perfect harmony between operational efficiency and reliability.

The deliberate exclusion of moving parts provides overwhelming advantages in industrial environments. Cooling fans represent common failure points in conventional LED fixtures—their mechanical bearings inevitably wear out, electric motors eventually fail, and blades rapidly accumulate dust and debris in typical warehouse or factory settings. A single fan failure triggers immediate LED overheating and premature fixture degradation. Coydon’s purely passive thermal solution completely eradicates these vulnerabilities by design. It delivers unwavering long-term reliability that translates into genuine set-and-forget operation, making our fixtures ideally suited for difficult-to-access high-bay applications where reliability directly impacts operational continuity and maintenance budgets.

2.4. Structural Integrity and Environmental Protection

The compact, unitary construction of the UFO design inherently delivers superior structural integrity compared to traditional lighting assemblies. The robust die-cast aluminum composition provides exceptional resistance to mechanical vibrations and minor impacts, offering crucial protection in demanding environments like manufacturing facilities, assembly plants, and locations with heavy machinery operation. This inherent ruggedness ensures the fixture housing and its sensitive internal components remain securely protected throughout years of service in challenging conditions.

Furthermore, the seamless, monolithic nature of the housing directly enables the achievement of stringent IP65 environmental protection ratings. This certification verifies complete protection against dust ingress and safeguards against low-pressure water jets from any direction, making the fixtures suitable for diverse environments including warehouses requiring regular cleaning, food processing facilities, and other locations with moisture exposure. The impeccable seal integrity prevents harmful contaminants like abrasive dust particles and corrosive moisture from penetrating the enclosure. This comprehensive protection strategy effectively shields sensitive internal components – particularly the LED driver and electrical connections – significantly enhancing both operational safety and the fixture’s dependable performance throughout its extended service life in demanding industrial applications.

3. The Direct Benefits - How Coydon's UFO Design Translates to User Value

3.1. Sustained Lumens and Unmatched Longevity

The advanced thermal management in Coydon’s UFO LED high bay lights directly enables exceptional performance consistency. Our fixtures maintain a high luminous efficacy of 150 lumens per watt throughout their lifespan, not just at the beginning. Superior heat dissipation is the key to this performance. By maintaining low junction temperatures, the LED chips experience minimal lumen depreciation. This means the bright, uniform illumination you experience on day one remains virtually unchanged for years.

This reliability is backed by a robust 5-Year Warranty. This confidence stems from our engineered solution to the primary cause of LED failure. The extended lifespan, typically exceeding 50,000 hours, drastically reduces replacement frequency and associated costs. This longevity is the cornerstone of lowering your Total Cost of Ownership. You invest not just in light, but in decades of dependable operation, minimizing both maintenance interruptions and long-term capital expenditure.

3.2. Peak Energy Efficiency and Maximum ROI

LEDs operate at their most efficient state when kept cool. Coydon’s superior heat dissipation ensures the 150 lm/W efficacy rating is a real-world, sustained achievement, not just a laboratory figure. This translates directly into maximum energy savings. The efficiency gain is stark when compared to traditional lighting. For instance, our 200W UFO LED High Bay Light can directly replace a 400W Metal Halide fixture, delivering equivalent or superior light levels while consuming half the electricity.

This results in dramatic cost savings. A single replacement can save approximately 200W per hour. Over 5,000 annual operating hours, this saves 1,000 kWh per fixture. These savings compound significantly across an entire facility. Furthermore, our optional microwave motion sensors and 0-10V dimming capabilities synergize perfectly with the efficient core design. These features allow lights to operate at reduced power or turn off when areas are unoccupied. The robust thermal design ensures stable performance even with frequent switching and dimming, enabling unparalleled energy conservation without compromising reliability or lifespan.

3.3. Optical Precision: Perfect Light Where You Need It

The circular “UFO” platform provides an ideal optical canvas for precise light control. Unlike linear or bulky traditional fixtures, the symmetrical shape allows for optimal arrangement of LEDs and secondary optics. Coydon Lighting offers beam angles of 60°, 90°, and 120° to cater to diverse application needs. A 60° beam creates a focused pool of light ideal for high-bay aisles, while a 120° beam provides widespread illumination for open areas.

This precise optical engineering ensures light is directed exactly where it is needed, eliminating wasted spill light and “light pollution” in the upper reaches of a facility. This increases utilization efficiency, meaning you need fewer lumens from the fixture to achieve the same usable illuminance on the work surface. In contrast, traditional Metal Halide lamps are omnidirectional, requiring large, inefficient reflectors to direct light downward – a process that inherently absorbs and wastes a substantial portion of the generated light. Coydon’s solution delivers superior visual comfort and task lighting efficiency directly by design.

4. Beyond the Theory - Coydon Lighting in Action

4.1. The Coydon Lighting Promise: Quality in Every Detail

Our commitment to excellence extends beyond thermal engineering to every component. We integrate OSRAM LED chips, a global leader in lighting technology, to guarantee exceptional color consistency, high lumen output, and long-term reliability from the light source itself. This ensures every fixture delivers the performance we promise.

The built-in LED driver features a wide voltage input (AC 90V-305V), providing exceptional operational stability. It automatically adapts to voltage fluctuations common in industrial grids, ensuring consistent performance and protection against power irregularities. This makes our fixtures robust and versatile for global applications. Furthermore, the fixture achieves an IP65 rating, certifying complete protection against dust ingress and low-pressure water jets. This rugged construction ensures reliable operation in demanding environments such as warehouses, manufacturing plants, and damp locations, safeguarding the investment against harsh conditions.

4.2. From Specification to Illumination: Our Support Services

We believe your investment should be backed by certainty. That’s why we offer a complimentary professional Dialux lighting simulation report before you purchase. This service goes beyond simple product specification, providing a data-driven preview of your space’s illumination. We model your specific layout to predict light levels, uniformity, and overall performance, ensuring the proposed solution perfectly matches your requirements and avoids costly over-lighting or under-lighting.

Our expert technical support team is an integral part of our service. We provide personalized consultation to help you select the optimal wattage, beam angle, and mounting height for your unique space and tasks. This ensures you achieve the perfect lighting solution, maximizing both energy efficiency and visual comfort. With Coydon Lighting, you gain more than a product; you gain a trusted partner dedicated to illuminating your success from planning to installation.

Conclusion: The Intelligent Choice for Demanding Environments

The Coydon Lighting UFO LED High Bay light embodies a perfect synthesis of intelligent engineering and practical design. Its iconic form is not merely aesthetic but represents a dedicated thermal management system that directly addresses the fundamental challenge of LED performance. This engineering-first approach delivers undeniable core value: exceptional longevity, sustained high efficiency, and unwavering optical performance throughout its extended service life.

By choosing Coydon Lighting, you select more than just a lighting product. You invest in a reliable, high-efficiency solution that guarantees a superior return on investment. Our fixtures are engineered to provide consistent, high-quality illumination while significantly reducing operational costs and maintenance demands. For any commercial or industrial environment where performance and reliability are non-negotiable, Coydon Lighting stands as the clear, intelligent choice for a brighter, more efficient future.

Illuminate Your Space with Confidence

Ready to experience how superior thermal engineering translates to real-world performance and savings? The proof is in the illumination. Stop compromising with lighting solutions that degrade over time.

Click the ‘Inquiry Now’ button below to take the first step. Receive a personalized quote tailored to your specific needs and unlock your FREE, professional Dialux simulation report. This detailed analysis will show you exactly how our UFO LED High Bay lights will perform in your unique space before you make any commitment.

Do not settle for uncertainty. Contact Coydon Lighting today. Let our experts help you design a lighting system that is as reliable, efficient, and high-performing as your operation demands. Illuminate your space with the confidence that only proven engineering can provide.