1. Introduction: The Hidden Threat to Your Outdoor Lighting Investment

Your outdoor lighting investment faces constant environmental threats. LED high bay lights without proper protection degrade quickly. Water infiltration causes short circuits and corrosion. Dust accumulation reduces light output and causes overheating. Extreme temperature fluctuations stress electronic components. These failures happen gradually but impact operations significantly.

Industry data reveals alarming statistics about inadequate lighting protection. Facilities using non-rated fixtures report 35% higher maintenance costs annually. The Lighting Research Center found water damage causes 28% of all outdoor lighting failures. Each failure requires 2-3 hours of maintenance labor plus replacement costs. Unplanned downtime affects productivity and safety simultaneously.

Consider this real scenario. A distribution center used standard fixtures in their loading dock area. Within 18 months, 40% of their lights failed due to rain and dust exposure. They faced $15,000 in emergency repairs plus productivity losses. Their experience demonstrates why proper protection matters fundamentally for outdoor applications.

The solution exists in international protection standards. Ingress Protection ratings provide clear guidelines for environmental resilience. Among these ratings, IP65 stands out for outdoor LED high bay light applications. This specific combination of dust and water protection transforms lighting durability completely.

1.1 Understanding the IP65 Advantage

IP65-rated fixtures offer comprehensive protection where standard lights fail. They withstand harsh weather conditions effectively. They maintain consistent performance through seasonal changes. They reduce maintenance frequency dramatically. They extend operational lifespan significantly. They provide reliable illumination when needed most.

Facilities upgrading to IP65-rated lighting report immediate improvements. Maintenance costs typically decrease by 60-70% in the first year. Energy savings increase due to sustained efficiency. Safety improves with reliable illumination. Productivity benefits from consistent lighting quality. The return on investment becomes apparent quickly.

The fundamental question remains unanswered for many decision-makers. What exactly does IP65 mean for outdoor LED high bay lights? How does this rating provide such substantial benefits? Why should this specification become your minimum standard? Understanding these answers transforms lighting from an expense to a strategic investment.

Choosing the right protection level requires informed decisions. IP65 represents the optimal balance for most outdoor applications. It provides adequate protection without unnecessary costs. It meets international testing standards rigorously. It delivers proven performance in real-world conditions. It represents the new benchmark for reliable outdoor illumination.

2. What is an IP Rating? Decoding the Ingress Protection Code

An IP Rating is a globally recognized standard. It classifies the level of protection provided by electrical enclosures. The International Electrotechnical Commission established this system. Their standard IEC 60529 defines testing procedures clearly. This code appears as “IP” followed by two digits. It provides objective data about environmental resilience.

The first digit indicates protection against solid objects. This includes dust, tools, and human contact. The scale ranges from 0 to 6 precisely. A rating of 0 means no protection exists. A rating of 6 represents complete dust tightness. Each number corresponds to specific test conditions. Understanding this scale ensures proper equipment selection.

The second digit represents liquid ingress protection. It measures resistance to water exposure. The scale ranges from 0 to 9 inclusively. Higher numbers indicate better water resistance. This testing involves controlled water exposure. Conditions become progressively more challenging. The rating reflects successful test completion.

2.1 Common Misconceptions Clarified

Many people misunderstand IP rating terminology. “Waterproof” suggests complete impermeability. This term lacks precise technical definition. “Water-resistant” indicates limited protection. IP ratings provide specific performance data. They describe proven laboratory test results.

IP65 does not mean submersible protection. It protects against low-pressure water jets. Complete immersion requires IP67 or IP68 ratings. Understanding this distinction prevents costly mistakes. It ensures appropriate product selection.

Another misconception involves dust protection. Some assume all enclosures resist dust naturally. Only IP5X or IP6X ratings guarantee dust protection. Lower ratings offer limited or no protection. Dust accumulation causes multiple problems. It reduces thermal performance significantly. It can create electrical safety hazards too.

Manufacturers must test products rigorously. Independent laboratories conduct standardized tests. They follow IEC 60529 methodology exactly. Products receive ratings only after passing tests. This verification process ensures reliability. It provides confidence in product performance.

2.2 Practical Application Understanding

IP ratings help compare products objectively. They eliminate marketing ambiguity completely. Facility managers can specify requirements precisely. Contractors can select appropriate products confidently. The system creates common language worldwide.

Different environments demand different IP ratings. Indoor offices might need IP20 protection. Outdoor areas typically require IP65 minimum. Washdown areas need IP66 or IP67 ratings. Understanding these requirements prevents problems.

The IP rating system continues evolving. New environmental challenges emerge regularly. The standard adapts to address these challenges. It remains relevant across industries globally. From consumer electronics to industrial lighting. Everyone benefits from this clear classification system.

3. IP65 Explained: The Gold Standard for Outdoor LED High Bay Lights

IP65 represents the ideal protection balance. It combines maximum dust protection with substantial water resistance. This specific combination meets most outdoor lighting needs perfectly. The rating provides concrete performance guarantees. Manufacturers must prove compliance through standardized testing. This verification process ensures consistent quality.

Outdoor LED high bay lights face multiple environmental challenges simultaneously. They encounter dust storms and heavy rainfall. They withstand temperature extremes and humidity changes. IP65 addresses these combined threats effectively. It creates a sealed environment for sensitive electronics. This protection extends product lifespan dramatically.

3.1 What Does “6” Mean? Dust-Tight Protection

The first digit “6” indicates complete dust protection. This represents the highest solid particle rating available. It means no dust ingress occurs under test conditions. The enclosure prevents all dust penetration completely. Even fine particulate matter cannot enter the fixture.

Dust protection prevents multiple operational problems. Accumulated dust reduces light output significantly. It creates thermal insulation on heat sinks. This causes LED overheating and premature failure. Dust can also create electrical conduction paths. This leads to short circuits and component damage.

Industrial environments generate substantial airborne particles. Manufacturing creates metal shavings and plastic dust. Warehouses circulate packaging materials and fibers. Construction sites produce concrete and wood particles. Ports and logistics centers have road dust and exhaust residues. All these require IP6X protection.

The testing for IP6X involves specific procedures. Test dust consists of fine talcum powder. It circulates in a sealed test chamber for eight hours. The enclosure must prevent any dust entry completely. Even microscopic particles cannot penetrate successfully. This ensures real-world dust protection reliability.

3.2 What Does “5” Mean? Resistance to Low-Pressure Water Jets

The second digit “5” indicates water jet protection. It means resistance to low-pressure water from any direction. Test nozzles spray water at specific flow rates. The enclosure withstands this exposure without water ingress. This protection level handles common outdoor conditions.

Rain protection represents the primary application. Outdoor fixtures face vertical and wind-driven rain. Snow and ice melting create water exposure too. Sprinkler systems and cleaning procedures involve water jets. IP65 ensures these activities don’t damage lighting fixtures.

The testing specification defines precise parameters. Nozzle diameter measures 6.3 millimeters exactly. Water pressure reaches 30 kPa at minimum distance. Flow rate equals 12.5 liters per minute. Testing duration continues for three minutes minimum. The enclosure rotates during testing for full coverage.

Important limitations exist for IP65 protection. It does not cover high-pressure washing systems. Industrial cleaning often uses stronger water jets. It does not permit any water immersion whatsoever. Temporary submersion requires IP67 rating instead. Permanent submersion needs IP68 protection.

3.3 Why IP65, Not Just “Weatherproof”?

Marketing terms lack standardized definitions. “Weatherproof” means different things to different manufacturers. Some use it for basic rain protection only. Others imply comprehensive environmental resistance. This ambiguity creates confusion and risk.

IP65 provides laboratory-verified performance data. It follows International Electrotechnical Commission standards. Independent testing confirms compliance objectively. The rating appears only after successful completion. This process eliminates marketing exaggeration.

Facility managers need reliable specifications. They base purchasing decisions on concrete data. Maintenance schedules depend on performance guarantees. Safety considerations require proven protection levels. IP65 delivers this certainty consistently.

Comparing products becomes straightforward with IP ratings. Different manufacturers’ IP65 products offer equivalent protection. This standardization simplifies procurement processes. It enables accurate cost-benefit analysis too. Decision-makers can focus on other important features.

The construction industry recognizes IP65 universally. Electrical codes reference IP ratings frequently. Engineering specifications include IP requirements regularly. Contractors understand and implement these standards daily. This common understanding prevents installation errors.

4. Why IP65 is Non-Negotiable for Outdoor LED High Bay Lights

Choosing lighting protection requires careful consideration. IP65 represents more than just technical specification. It becomes a fundamental requirement for reliable operations. Outdoor LED high bay lights operate in exposed locations constantly. Their performance directly impacts facility safety and productivity. Compromising on protection creates multiple risk factors.

Industrial facilities face increasing operational demands. Lighting must perform reliably under all conditions. Unexpected failures create safety hazards immediately. They disrupt workflows and increase operational costs. IP65 provides assurance against these problems systematically. It transforms lighting from potential liability to reliable asset.

4.1 Protection Against Environmental Hazards

Outdoor environments present diverse challenges daily. Water exposure occurs in multiple forms consistently. Rain varies from gentle drizzle to torrential downpour. Snow accumulation then melting creates prolonged moisture. Hail storms present impact and water penetration risks. Coastal areas add salt spray corrosion concerns too.

Dust and particulate matter cause gradual damage. Fine dust infiltrates unprotected fixtures slowly. It accumulates on optical surfaces and electronics. Sand and grit create abrasive wear on surfaces. Industrial pollutants include chemical residues often. These accelerate corrosion and component degradation significantly.

Temperature fluctuations stress materials continually. Daily and seasonal changes cause expansion and contraction. This mechanical stress weakens seals over time. Humidity variations affect electrical connections directly. Condensation forms inside inadequately sealed fixtures. This creates ideal conditions for corrosion development.

Biological factors also impact unprotected lighting. Insects seek warmth inside fixtures naturally. Their presence blocks light and creates residues. Mold and mildew grow in moist environments readily. Bird droppings contain corrosive compounds frequently. All these require proper sealing for prevention.

4.2 Enhancing Performance And Longevity

Light output stability depends on cleanliness. Dust accumulation reduces lumen output progressively. Water ingress creates optical surface damage permanently. Both factors combine to diminish illumination quality. IP65 maintains optimal lighting conditions consistently. This ensures planned illumination levels remain constant.

Component protection extends operational lifespan dramatically. LED drivers contain sensitive electronic components. Dust causes overheating and insulation breakdown. Water creates short circuits and corrosion damage. Both lead to premature failure inevitably. Proper sealing prevents these failure mechanisms completely.

Internal heat management requires clean surfaces. Dust acts as thermal insulation on heat sinks. This reduces cooling efficiency substantially. LEDs operate at higher temperatures consequently. Their lifespan decreases according to thermal stress. IP65 maintains optimal thermal performance consistently.

Case Study Comparison Data

A manufacturing facility tested different fixture types. They installed both IP65 and standard fixtures simultaneously. The environment included dust and occasional water exposure. Results showed significant performance differences clearly.

IP65 fixtures maintained 95% lumen output after two years. Standard fixtures dropped to 78% output in same period. Maintenance requirements differed substantially too. IP65 fixtures needed only annual cleaning. Standard fixtures required quarterly maintenance minimum. Total cost of ownership showed 40% savings with IP65.

Failure rates demonstrated even greater contrasts. IP65 fixtures experienced 2% failure rate annually. Standard fixtures showed 15% failure rate consistently. This translated to significant operational disruptions. Production delays occurred during fixture replacements frequently.

Energy consumption remained stable with IP65 fixtures. Standard fixtures showed increasing power demand gradually. Dust accumulation changed thermal characteristics apparently. Drivers compensated by drawing more current consequently. This increased energy costs by 8% over two years.

4.3 Safety And Compliance

Electrical safety requires complete moisture exclusion. Water and electricity create dangerous combinations always. IP65 prevents water contact with live components effectively. This eliminates electrocution risks completely. It also prevents short circuit incidents reliably.

Fire prevention depends on proper component protection. Dust accumulation creates potential ignition sources. Electrical arcing can ignite combustible materials. Overheating components may start fires too. IP65 eliminates these fire hazards systematically. This protects both property and personnel safety.

Regulatory compliance demands specific protection levels. OSHA regulations address workplace lighting requirements. They mandate adequate protection for environmental conditions. NFPA standards cover electrical installation safety. They reference IP ratings for outdoor applications specifically.

International standards provide additional guidance. IEC specifications define testing methodologies precisely. They ensure consistent protection across manufacturers. Local building codes incorporate these standards frequently. Compliance avoids legal liabilities and insurance issues.

Insurance considerations favor properly rated equipment. Many policies require appropriate environmental protection. Claims may be denied for inadequate fixture ratings. Risk assessment includes lighting protection levels typically. Proper ratings demonstrate due diligence effectively.

Industry certifications provide independent verification. Third-party testing confirms protection claims objectively. This builds confidence in product specifications completely. It also simplifies procurement approval processes significantly. Documentation supports maintenance and compliance audits.

5. Coydon Lighting’s IP65 UFO LED High Bay Lights: Engineered for Extreme Conditions

100 Watt

KD-HBD-W100-1

Ø248mm X 129mm

150 Watt

KD-HBD-W150-1

Ø295mm X 140mm

200 Watt / 240 Watt

KD-HBD-W200-1 / KD-HBD-W240-1

Ø320mm X 154mm

| Input Voltage: | AC 90V – 305V | |

| Colour Temperature: | 3000K / 4500K / 6000K | |

| Color Rendering Index: | 80+ | |

| LED Type: | LED SMD 2835 ( OSRAM ) | |

| IP Grade: | IP65 | |

| Material: | Aluminium + PC Lens | |

| Luminous Efficiency: | 150 Lumens per watt | |

| Beam Angle: | 60° / 90° / 120° | |

| Warranty: | 5 Years | |

| Mounting Height: | 100 Watt: 15–20 ft (4.5–6 m) 150 Watt: 20–30 ft (6–9 m) 200 Watt: 30–40 ft (9–12 m) 240 Watt: 40–50 ft (12–15 m) |

Coydon Lighting specializes in industrial lighting solutions. Our IP65 UFO LED high bay lights represent engineering excellence. They combine advanced protection with superior performance. Each fixture undergoes rigorous quality testing. We design products for real-world industrial challenges. Our solutions deliver measurable operational improvements.

The KD-HBD series embodies our technical expertise. These fixtures meet demanding environmental requirements perfectly. They maintain performance in harsh conditions consistently. Our engineering team focuses on reliability and efficiency. We understand industrial lighting challenges thoroughly. Our products reflect this deep industry knowledge.

5.1 Product Highlights: KD-HBD Series

Lighting efficiency reaches exceptional levels in our series. Each fixture delivers 150 lumens per watt consistently. This represents industry-leading energy efficiency standards. Facilities reduce energy consumption by over 50% typically. The savings translate directly to lower operational costs.

Intelligent control features provide operational flexibility. Microwave sensors detect motion automatically. They adjust lighting levels based on occupancy patterns. This eliminates energy waste in unoccupied areas. 1-10V dimming enables precise brightness control. Users can adjust lighting for specific tasks easily.

Power replacement capabilities offer immediate benefits. Our 200W UFO LED high bay light replace 400W metal halide lights effectively. This cuts energy consumption by half immediately. Light quality improves significantly with better color rendering. The transition requires minimal electrical modifications too.

Structural design ensures long-term reliability. Aluminum heat sinks provide optimal thermal management. They maintain LED temperatures within safe ranges constantly. Tempered glass lenses offer superior durability. They withstand impact and temperature extremes effectively. Reinforced seals maintain IP65 protection throughout product life.

Additional Technical Specifications

The fixtures feature high-quality LED chips. They provide consistent color temperature output. Color rendering index exceeds 80 typically. This ensures accurate visual perception in workspaces. Light distribution patterns optimize workspace illumination.

Electrical components meet international standards. Drivers carry CE and UL certifications. They operate within wide voltage ranges reliably. Power factor correction exceeds 0.9 consistently. This reduces energy waste and improves grid efficiency.

Installation flexibility enhances application possibilities. Multiple mounting options accommodate different ceiling types. Adjustable suspension kits simplify height adjustments. The fixtures work with various electrical systems seamlessly. This reduces installation time and complexity significantly.

Maintenance requirements remain minimal consistently. The sealed design prevents internal contamination. External surfaces resist dust accumulation effectively. Cleaning requires only occasional wiping normally. This reduces long-term maintenance costs substantially.

5.2 Real-World Application: Project Case Study

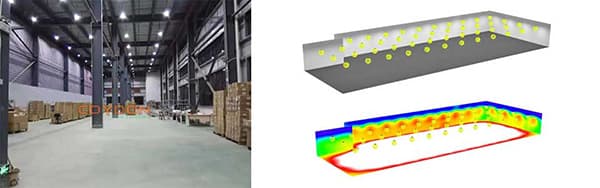

The calculation report: UFO LED high bay lights 150 watt x 46 piece ( Project 02 )

Our recent warehouse project demonstrates practical benefits. The facility required lighting for storage operations. They needed consistent illumination for inventory management. Safety considerations demanded reliable lighting throughout.

We installed 46 UFO LED high bay lights strategically. The layout followed detailed lighting calculations precisely. Mounting height reached 7 meters above floor level. The fixtures distributed light evenly across the workspace.

Measurement results confirmed performance expectations. Average illuminance reached 338 lux on workplanes. This exceeded industry standards for warehouse operations. Uniformity ratios achieved optimal levels throughout. Minimum illuminance reached 131 lux in all areas.

Energy efficiency metrics showed significant improvements. Connected load measured 2.90 watts per square meter. This represented substantial reduction from previous systems. Specific power consumption reached 0.86 W/m²/100 lux. These numbers demonstrate exceptional energy efficiency.

The client reported multiple operational benefits. Lighting quality improved visual comfort immediately. Employees reported reduced eye strain during shifts. Inventory accuracy increased due to better visibility. Safety incident rates decreased noticeably too.

Financial and Operational Outcomes

Energy consumption decreased by 62% annually. This translated to $18,500 in yearly savings directly. Maintenance costs reduced by 75% compared to previous systems. The facility eliminated quarterly cleaning requirements completely.

Lighting performance remained consistent over time. After twelve months, lumen maintenance exceeded 95%. Color temperature stability maintained optimal levels. The client reported zero fixture failures during this period.

Return on investment calculations showed positive results. Payback period reached only 1.8 years typically. Total cost of ownership decreased by 40% over five years. These financial metrics justified the investment completely.

5.3 Dialux Simulation: See the Light Before You Buy

Professional lighting planning requires accurate visualization. Dialux simulation provides this capability perfectly. Our team creates detailed lighting simulations for clients. These show expected results before installation begins.

The simulation process starts with space analysis. We collect room dimensions and surface reflectances. Lighting requirements get defined based on activities. Our software then calculates optimal fixture placement.

Visual outputs include multiple representation formats. False color renderings show illuminance distribution clearly. 3D models demonstrate lighting effects realistically. Point-by-point calculations provide precise data tables.

Clients receive comprehensive simulation reports. These include all technical specifications and results. Performance metrics show expected energy consumption. Maintenance predictions help plan operational schedules.

Simulation Benefits and Applications

Planning accuracy improves significantly with simulations. Clients can evaluate different layouts easily. They compare various fixture options effectively. This prevents costly installation mistakes completely.

Budget forecasting becomes more reliable with simulations. Energy savings predictions gain accuracy substantially. Maintenance cost estimates improve significantly too. Total cost of ownership calculations become more precise.

Regulatory compliance verification happens through simulations. Lighting levels meet industry standards precisely. Energy codes get satisfied automatically. Safety requirements receive proper consideration always.

Our simulation service remains free for qualified projects. Clients receive professional lighting designs without cost. This demonstrates our commitment to customer success fully. It also ensures optimal lighting solutions consistently.

6. How to Choose the Right IP Rating for Your Facility

Selecting the optimal IP rating is a strategic decision. It balances protection needs with budget considerations wisely. Understanding rating differences prevents costly mistakes effectively. This guide provides practical selection methodology clearly.

6.1 Understanding IP Rating Differences: A Practical Comparison

IP ratings vary significantly in protection levels. IP44 offers basic splash and dust protection only. It suits covered outdoor areas with minimal exposure. IP65 provides complete dust tightness plus water jet resistance. This covers most outdoor industrial applications perfectly. IP67 adds temporary immersion protection capability. It serves flood-prone or washdown environments specifically.

Each rating addresses different risk profiles appropriately. Using IP44 where IP65 is needed causes failures. Choosing IP67 for simple outdoor use wastes resources. Matching the rating to actual conditions is crucial. Consider both current and potential future exposures carefully.

Comparison Table for Quick Reference

| Rating | Dust Protection | Water Protection | Best For |

| IP44 | Limited ingress | Splashes only | Indoor workshops, covered canopies |

| IP65 | Dust-tight | Low-pressure jets | Warehouses, parking lots, building exteriors |

| IP67 | Dust-tight | Temporary immersion | Food processing, chemical plants, pool areas |

6.2 Self-Assessment Guide: Evaluate Your Facility's Needs

Begin with dust environment assessment thoroughly. Observe airborne particle levels during operations. Note if processes generate fine particulates regularly. Consider seasonal variations like pollen or sand storms. High dust environments demand IP6X protection absolutely.

Water exposure analysis requires careful observation. Determine if areas receive direct rainfall exposure. Check if cleaning involves water spray or jets. Assess potential for flooding or water accumulation. Temporary water contact needs higher ratings obviously.

Temperature and corrosion factors influence materials. Extreme temperatures affect seal performance significantly. Chemical fumes require special protective coatings. Salt environments need corrosion-resistant materials. These considerations impact product selection directly.

Practical Self-Evaluation Steps

Document your facility conditions systematically. Take clear photographs of installation areas. Note dimensions and mounting heights precisely. Record existing lighting levels if possible. This information helps professional assessment greatly.

Consider operational patterns and schedules too. Areas with frequent washdown need higher ratings. Spaces with occasional cleaning require less protection. Understanding usage patterns ensures appropriate selection.

6.3 Professional Support: Coydon Lighting's Free Remote Consultation

International clients benefit from our remote services. We provide expert guidance without geographical limitations. Our engineers analyze your facility conditions digitally. This ensures appropriate product recommendations consistently.

The consultation process begins simply. Share facility photos and videos through our portal. Provide dimensional drawings or layout plans digitally. Describe operational conditions and requirements clearly. Our team processes this information professionally.

Virtual lighting simulation creates accurate previews. We show expected illumination levels visually. Energy consumption calculations appear precisely. Performance predictions help decision-making effectively. This eliminates guesswork completely.

Receive personalized product recommendation reports. These include technical specifications comprehensively. Installation guidance comes with each recommendation. Maintenance requirements get outlined clearly too. Ongoing support remains available always.

Contact our technical team today conveniently. Share your facility information through our online form. Receive professional recommendations within 48 hours typically. Transform your lighting with confidence completely.

7. Beyond IP65: Additional Features That Matter

IP65 provides essential environmental protection always. However, some facilities require additional special features. These capabilities address specific operational challenges effectively. Understanding these options ensures optimal lighting solutions.

Industrial environments present unique conditions frequently. Standard fixtures may not perform adequately sometimes. Specialized features overcome these limitations successfully. They extend fixture lifespan in extreme conditions significantly.

7.1 High Temperature Tolerance

Certain environments generate extreme heat consistently. Boiler rooms and foundries reach high temperatures regularly. Commercial kitchens experience sustained thermal exposure. Standard LED fixtures degrade rapidly under such conditions.

High-temperature fixtures use specialized components extensively. Thermal management systems become more robust significantly. Heat sinks feature advanced aluminum alloys typically. Drivers operate reliably at elevated temperatures consistently. These fixtures withstand up to 60°C ambient temperature typically.

Materials selection becomes critical for heat resistance. High-temperature wires and cables get used exclusively. Thermal compound applications improve heat transfer effectively. Special seals maintain integrity despite thermal cycling reliably.

7.2 Corrosion-Resistant Coatings

Chemical environments require additional protection always. Manufacturing plants emit corrosive fumes frequently. Coastal locations face salt spray exposure constantly. Food processing involves acidic cleaning solutions regularly.

Protective coatings create durable barriers effectively. Epoxy powder coatings provide chemical resistance reliably. Anodized aluminum surfaces resist oxidation successfully. Stainless steel components prevent rust formation completely. These features extend product life in harsh conditions significantly.

Special attention focuses on fastener protection specifically. Coated screws and bolts resist chemical attack effectively. Plated mounting hardware maintains structural integrity reliably. This prevents fastener failure in corrosive environments completely.

7.3 Intelligent Control Systems

Modern lighting demands smart energy management. Intelligent controls optimize energy consumption effectively. They adapt lighting to actual usage patterns intelligently. This reduces operational costs substantially consistently.

Microwave sensors detect occupancy accurately. They adjust lighting levels based on presence automatically. Scheduled dimming follows operational hours precisely. Daylight harvesting utilizes natural light effectively. These strategies reduce energy waste significantly.

Networked systems enable centralized management conveniently. Facility managers monitor all fixtures remotely easily. Usage data helps optimize operational schedules effectively. Maintenance alerts prevent unexpected failures successfully.

Integration capabilities provide additional flexibility. Systems connect with building management seamlessly. They support various communication protocols widely. This ensures compatibility with existing infrastructure perfectly.

Advanced control strategies deliver maximum savings. Time-based controls follow operational patterns accurately. Task tuning adjusts lighting for specific activities precisely. Personal control empowers individual users effectively. These approaches minimize energy consumption optimally.

8. Conclusion: Invest in Protection, Reap the Rewards

The IP65 rating represents more than technical specification. It embodies a commitment to operational excellence always. Proper environmental protection transforms lighting investments completely. It changes fixtures from recurring expenses to lasting assets.

IP65 delivers measurable returns consistently. Reliability increases dramatically with proper sealing. Safety improves through moisture and dust exclusion. Return on investment grows with extended lifespan. These benefits justify the initial investment completely.

Choose lighting based on proven performance data. Laboratory testing ensures real-world reliability. Certified ratings provide confidence in product capabilities. This approach prevents costly operational disruptions effectively.

Coydon Lighting stands behind every product fully. We manufacture fixtures with rigorous quality standards. Our engineering team understands industrial challenges deeply. We provide solutions that perform in demanding conditions consistently.

Our commitment extends beyond product delivery always. Technical support remains available throughout product life. Customization options address specific requirements effectively. Complete service ensures customer satisfaction completely.

Invest in protection that delivers lasting value. Choose fixtures that withstand environmental challenges reliably. Trust ratings that represent proven performance always. Partner with experts who understand your needs thoroughly.

Contact Coydon Lighting for your next project conveniently. Experience the difference proper protection makes significantly. Transform your facility lighting with confidence completely.

Call to Action: Light Up Your Space with Confidence

Your perfect lighting solution awaits discovery now. Take the first step toward superior illumination today. Transform your facility with reliable, efficient lighting technology. Experience the Coydon Lighting difference personally.

Click the “Inquiry Now” button immediately. Begin your lighting transformation journey today. Our technical team responds within 24 hours typically. Professional guidance ensures optimal solutions consistently.

Request your free Dialux simulation report conveniently. See your lighting plan come to life visually. Verify performance before making investments completely. This eliminates uncertainty from decision-making effectively.

Obtain detailed product specifications easily. Study technical data and performance metrics thoroughly. Review case studies from similar facilities conveniently. Understand real-world application benefits clearly.

Discuss customized solutions with our experts directly. Explore motion sensor integration possibilities. Consider dimming control system options. Address special environmental requirements effectively. Create lighting perfectly suited to your needs.

Schedule your professional assessment today. Share your facility information through our secure portal. Receive personalized recommendations promptly. Make informed decisions with confidence always.

Contact Coydon Lighting without delay now. Join satisfied clients worldwide successfully. Illuminate your space with excellence today.