1. Introduction: Why Your Warehouse Lighting Could Be Costing You Thousands

1.1 Are You Paying Thousands More Than Necessary for Warehouse Lighting?

If your facility still relies on traditional metal halide, fluorescent, or high-pressure sodium high bay lights, you’re not just illuminating your space – you’re funding an energy-draining system that silently consumes profits every single day. Most facility managers see only the electricity bill, but the true cost of outdated lighting runs much deeper, affecting every aspect of operations from maintenance budgets to worker productivity and even safety records. The lighting solution you installed years ago might be costing you far more today than you ever calculated.

1.2 The Hidden Costs Nobody Shows You

Consider the real expenses: specialized lifts and equipment for frequent bulb replacements, production downtime during maintenance, increased HVAC costs from excessive heat output, and gradual lumen depreciation that leaves areas under-lit long before bulbs actually fail. Traditional high bay lights can lose up to 40% of their brightness within just two years, forcing you to use more energy for diminishing light. Then factor in the warm-up time – precious minutes each morning when your space isn’t fully productive – and the disposal costs for hazardous materials. Suddenly, that “affordable” traditional lighting becomes an ongoing financial drain.

1.3 The Productivity Impact You Can't Ignore

Poor lighting quality directly affects your bottom line through reduced worker productivity and increased error rates. Flickering lights, inconsistent color rendering, and dark spots contribute to eye strain, fatigue, and decreased concentration. In manufacturing environments, this can mean more quality control issues. In warehouses, it can lead to mislabeled inventory or slower picking times. In retail spaces, it makes products look less appealing. Your lighting isn’t just an overhead cost – it’s either supporting or hindering your core business operations every single day.

1.4 Beyond Basic Energy Savings: The LED Transformation

Modern LED high bay light represents more than just an energy-efficient alternative. It’s a complete operational upgrade that transforms lighting from a cost center into a strategic asset. Imagine fixtures that provide instant, full brightness with superior color accuracy that makes details pop. Picture lighting that maintains over 90% of its original output for years, with no flicker and no warm-up time. Envision a system that reduces your cooling costs, minimizes maintenance disruptions, and creates a safer, more productive environment – all while cutting your energy consumption by 60% or more.

1.5 What You'll Gain From This Ultimate Guide

This comprehensive guide goes beyond basic specifications to show you exactly how to select LED high bay lights that deliver maximum return on investment. We’ll provide real photometric data from actual installations, detailed case studies showing complete cost breakdowns, and practical guidance on everything from calculating your exact needs to implementing smart controls. You’ll learn why some “bargain” LED fixtures cost more in the long run, how to avoid common specification mistakes, and what features deliver the best value for your specific application.

Most importantly, we’ll show you how facilities identical to yours are achieving 50% or greater reductions in total lighting costs – not just energy savings, but combined savings from reduced maintenance, lower cooling loads, increased productivity, and extended lifespan. This isn’t theoretical; it’s proven results from warehouses, factories, and commercial spaces that have made the transition successfully.

1.6 Your Path to Smarter Lighting Starts Here

Whether you’re planning a complete facility retrofit or replacing failed fixtures, the decisions you make today will impact your operational costs for the next decade. By understanding exactly what to look for – and what to avoid – you can ensure your lighting investment pays dividends for years to come. Let’s begin with the fundamental question: What is your current lighting really costing you, and what could you save with the right LED solution?

2. What Are LED High Bay Lights and Where Are They Used?

2.1 Defining LED High Bay Lights

LED high bay lights are specialized industrial lighting fixtures designed specifically for spaces with elevated ceilings typically exceeding 15 feet (4.5 meters). Unlike conventional lighting, these systems deliver powerful, concentrated illumination downward to effectively cover large floor areas from significant heights. Their engineering focuses on maximizing vertical light penetration while maintaining uniform distribution, creating well-lit environments without dark spots or excessive glare.

2.2 Warehouses and Distribution Centers

In logistics environments, proper illumination directly impacts operational efficiency and safety. Uniform lighting enables accurate inventory identification across all shelf levels, reduces picking errors, and minimizes accident risks in busy aisles. Well-designed UFO LED high bay light systems eliminate shadows in loading areas where forklifts operate, creating safer working conditions. The consistent light levels also support barcode scanning systems that require specific illumination intensities for optimal performance.

2.3 Manufacturing Facilities and Production Lines

Industrial manufacturing demands precision lighting for quality control and worker productivity. High-quality LED high bay lights provide consistent color rendering that helps workers identify material defects and color variations. Proper illumination reduces eye strain during detailed assembly tasks, potentially decreasing error rates. In facilities operating multiple shifts, reliable instant-start lighting ensures consistent working conditions regardless of time of day, supporting continuous production schedules.

2.4 Sports Complexes and Gymnasiums

Athletic facilities require specialized lighting that supports both participant performance and spectator experience. LED high bay lights in these settings must provide excellent vertical illumination for ball tracking while minimizing glare that could distract athletes. Uniform light distribution across playing surfaces ensures fair competitive conditions. Many sports federations specify minimum illumination levels for different competition grades, making compliant lighting essential for hosting official events.

2.5 Retail Big-Box Stores and Commercial Spaces

Large-format retail environments use UFO LED high bay light to create inviting atmospheres that enhance product presentation. Proper lighting makes merchandise appear more vibrant and appealing while guiding customer flow through spacious layouts. In these applications, color rendering quality becomes particularly important for accurately displaying product colors. The right lighting can increase dwell time and potentially boost sales conversion rates in retail settings.

2.6 Transportation and Specialized Facilities

Beyond these primary applications, LED high bay lights serve aircraft hangars where maintenance precision is critical, automotive dealerships that need to showcase vehicle details, and agricultural processing facilities requiring moisture-resistant fixtures. Their versatility stems from customizable configurations including various beam angles, color temperatures, and protective ratings that adapt to specific environmental challenges.

3. Key Benefits of Switching to LED High Bay Lights

3.1 Transformative Energy Savings

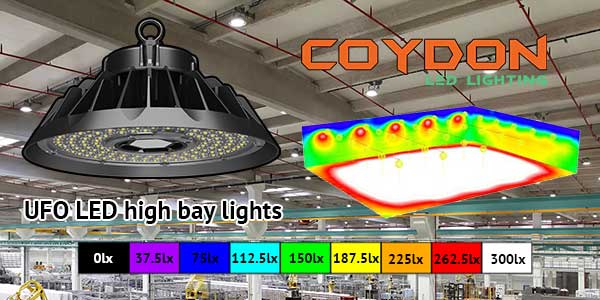

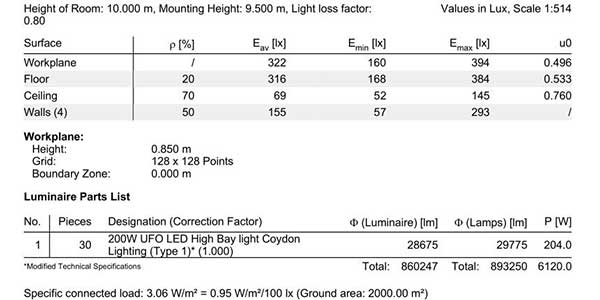

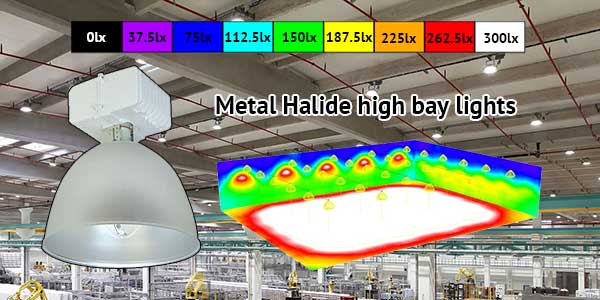

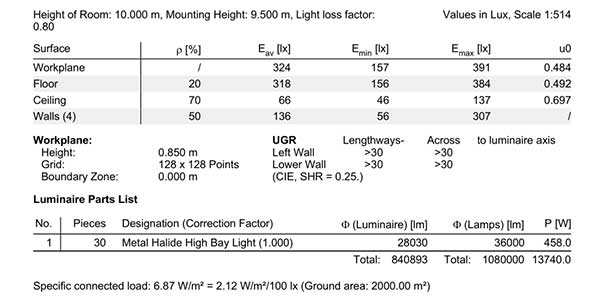

The most immediate benefit of LED high bay light conversion is dramatic energy reduction. Traditional metal halide fixtures consume excessive power while delivering diminishing light output. Our comparison data shows striking results: a 200W UFO LED high bay light replaces a 400W metal halide high bay light while providing superior illumination. This represents over 50% direct energy savings. Facilities operating 24/7 see even greater benefits. The photometric report from our warehouse case study demonstrates specific savings. Connected load decreased from 6.87 W/m² to 3.06 W/m² after LED conversion. This translates to thousands in annual electricity cost reductions.

3.2 Extended Longevity and Maintenance Reduction

LED technology offers exceptional operational lifespan exceeding 100,000 hours. Traditional metal halide lamps typically last only 15,000-20,000 hours. This difference eliminates frequent replacement cycles. Maintenance costs decrease substantially as a result. Facilities avoid expensive lift rentals for ceiling access. Production downtime for lighting maintenance becomes minimal. Coydon Lighting provides a comprehensive 5-year warranty. This ensures long-term performance reliability. Our fixtures maintain consistent light output throughout their lifespan. They resist lumen depreciation better than alternatives.

3.3 Enhanced Workplace Safety and Productivity

Superior lighting quality directly impacts operational efficiency. High CRI (80+) ensures accurate color representation. Workers distinguish details more easily with better lighting. Uniform illumination eliminates dangerous shadows in work areas. This reduces accident risks significantly. Proper lighting decreases eye strain and fatigue. Workers maintain higher concentration levels throughout shifts. Manufacturing precision improves with consistent lighting conditions. Quality control becomes more reliable and accurate. The instant-on capability of LED fixtures provides immediate full brightness. There is no warm-up period required unlike traditional options.

3.4 Positive Environmental Impact

LED high bay lights support sustainability initiatives effectively. They contain no mercury or hazardous materials. Disposal becomes simpler and safer as a result. Reduced energy consumption lowers carbon emissions substantially. Each converted fixture contributes to environmental protection. The long lifespan minimizes waste generation significantly. Fewer replacements mean less material in landfills. Energy efficiency aligns with corporate sustainability goals. Many organizations report their lighting upgrades in ESG disclosures. LED technology supports green building certifications too.

3.5 Smart Control Readiness and Advanced Features

Modern LED high bay lights offer intelligent control capabilities. Microwave sensor compatibility enables motion-activated lighting. This creates additional energy savings in low-traffic areas. 1-10V dimming provides flexible light level adjustment. Facilities can integrate daylight harvesting systems easily. These features optimize energy usage based on actual needs. Smart controls extend fixture lifespan further. Reduced operating hours mean longer service life. The technology supports building automation systems integration. Lighting becomes part of intelligent facility management.

3.6 Comprehensive Financial Benefits

The total financial impact extends beyond energy savings. Reduced maintenance costs create ongoing operational benefits. Lower cooling loads from efficient LEDs decrease HVAC expenses. Improved productivity represents significant value addition. Fewer errors and accidents reduce associated costs. The combined savings typically deliver ROI within 24 months. Government incentives and utility rebates often accelerate this further. LED conversion represents a strategic investment rather than an expense.

3.7 Future-Proof Technology Investment

LED high bay light technology continues advancing rapidly. Current installations remain compatible with emerging innovations. Smart city and IoT integrations become possible with proper infrastructure. Lighting systems can evolve with technological progress. This protects your investment against early obsolescence. The modular design allows easy upgrades when needed. Control systems can be enhanced without replacing fixtures. This ensures long-term relevance and functionality.

4. How to Choose the Right LED High Bay Light: A Step-by-Step Checklist

4.1 First Step: Measure Your Space And Define Requirements

Begin with accurate measurement of your facility using proper tools. Record ceiling height precisely with laser measuring devices. Calculate total floor area including all functional zones thoroughly. Note wall and ceiling reflection values carefully. Dark surfaces require more lumens for adequate illumination consistently. Identify specific task areas needing different light levels precisely.

Define your illumination requirements clearly without compromise. Warehouses need 20-50 foot-candles for basic operations typically. Manufacturing areas require 50-100 foot-candles generally. Retail spaces benefit from 75-100 foot-candles usually. Consider task-specific needs within each area comprehensively. Storage zones need less light than packing stations realistically.

Apply “Lighting Planning Before Buying” principle strictly. Create a detailed facility map with dimensions accurately. Mark obstacles like shelves and machinery clearly. Identify high-activity zones needing maximum illumination properly. Document existing electrical infrastructure locations completely. This planning prevents costly installation issues later effectively.

Professional photometric analysis ensures optimal results always. Our Dialux reports provide exact calculations reliably. They show illumination levels before purchase confidently. This scientific approach guarantees proper lighting absolutely. Facilities achieve desired brightness without waste successfully. Consider daylight availability in your space assessment. Natural light reduces artificial lighting needs significantly. Window placement affects lighting design decisions directly. Seasonal variations impact lighting requirements moderately. Account for all factors in your planning process. Involve facility managers in requirement discussions. They understand daily operational needs best. Their input ensures practical lighting solutions. Include maintenance personnel in planning meetings. They know access challenges for fixtures. This prevents future maintenance difficulties. Document all requirements systematically. Create a lighting specification document. This guides the selection process properly.

4.2 The Lumens-Watts Revolution: Why Old Rules Don't Apply

Forget traditional wattage-based selection methods completely. LED efficiency makes watts irrelevant for brightness comparison. Focus instead on actual light output measured in lumens. Higher lumens mean more visible light regardless of power consumption. Our photometric data proves this principle clearly without doubt.

Luminous efficacy (lm/W) represents true efficiency accurately. This measures lumens produced per watt consumed precisely. 150 lm/W marks the industry excellence threshold definitely. Coydon Lighting’s UFO LED high bay lights achieves 150+ lm/W consistently. This means more light with less energy consumption always. Traditional fixtures deliver only 80-100 lm/W typically. Our technology provides 50% better efficiency significantly.

Calculate total lumen requirements for your space methodically. Multiply area by desired foot-candle levels correctly. Add 20% for light loss factors appropriately. Divide by fixture lumens for quantity needed exactly. Consider actual case study data for verification confidently. Our warehouse project shows concrete results convincingly. Connected load decreased from 6.87 to 3.06 W/m² dramatically. This demonstrates the lumen-watt revolution in practice vividly. Energy savings exceed 50% while improving light quality remarkably.

Understand lumen depreciation over time thoroughly. LEDs maintain brightness better than traditional lights. Our fixtures show minimal lumen depreciation annually. This ensures consistent performance throughout lifespan. Compare initial versus maintained lumens carefully. Some manufacturers exaggerate initial lumen values. Our specifications show realistic performance data. We provide honest product information always.

Consider light distribution efficiency critically. Not all lumens reach the work surface equally. Optical design affects usable light percentage. Our fixtures optimize light distribution effectively. More lumens reach where needed most. This reduces total fixture requirements accordingly. Calculate based on delivered lumens properly. This ensures accurate quantity determination.

4.3 Beam Angle And Optics: Shaping Light for Your Specific Space

Beam angle determines light distribution pattern completely. 60° beams provide concentrated illumination ideal for high ceilings. They maximize vertical light penetration from 30+ feet effectively. 90° beams offer balanced coverage for standard applications. They work well in 20-30 feet mounting situations perfectly. 120° beams create wide, even illumination for lower ceilings. The choice depends on your ceiling height primarily.

Consider your specific spatial layout carefully. Different tasks require different light distribution patterns. UFO LED high bay light design excels in open spaces particularly. The circular optics provide symmetric light distribution evenly. This eliminates directional limitations found in linear fixtures. Our Dialux analysis shows superior uniformity with UFO designs. Open warehouses achieve better coverage with fewer fixtures economically.

Beam angle affects spacing between fixtures directly. Narrow beams require closer spacing typically. Wide beams allow greater distance between units. Proper spacing prevents dark spots between lights. It ensures consistent illumination across entire floor areas. Consider fixture layout patterns carefully. Symmetrical layouts provide best uniformity generally. Asymmetrical layouts suit specific needs sometimes.

Evaluate multiple beam angle options thoroughly. Our products offer 60°, 90°, and 120° choices. Select based on your specific requirements. Consider mounting height and area size together. Higher mounting needs narrower beams usually. Larger areas need wider beams generally. Professional advice helps selection process. Our experts provide beam angle recommendations.

Test different beam angles if possible. Pilot installations show actual performance. This prevents costly mistakes in large projects. Document beam angle selection rationale. This helps future reference and adjustments. Consider future layout changes possibly. Flexible beam angles accommodate changes easily.

4.4 Color Quality Matters: CCT And CRI Explained

Color temperature (CCT) affects visual perception significantly. 3000K provides warm, inviting light suitable for break rooms. 4000K offers neutral white ideal for general workspaces. 5000K delivers cool daylight-like illumination for tasks. Choose based on operational requirements carefully. Consider the psychological impact of different temperatures.

Warm light creates comfortable, relaxing environments perfectly. Cool light promotes alertness and concentration effectively. Neutral white balances both characteristics appropriately. Different areas may need different temperatures reasonably. Production areas often need cooler temperatures. Office spaces may prefer neutral white. Break rooms benefit from warmer tones.

CRI measures color accuracy under artificial light precisely. 80+ CRI represents good color rendering quality. 90+ CRI offers excellent accuracy for critical applications. Automotive shops need high CRI for paint matching. Retail spaces benefit from true color representation. Manufacturing facilities require accurate part identification.

Our UFO LED high bay lights series offers 3000K-5000K selections completely. High CRI versions ensure superior color quality consistently. Professional lighting design considers human factors. It also considers technical requirements thoroughly. Color consistency across fixtures matters greatly. Batch-to-batch variations should be minimal. Our quality control ensures color consistency.

Consider specific industry requirements carefully. Food processing needs particular color rendering. Textile manufacturing requires accurate color perception. Electronics assembly needs good contrast recognition. Match CRI to your specific applications. Higher CRI often justifies higher cost. The benefits outweigh additional investment.

Evaluate color rendering in actual conditions. View samples under working conditions. Compare different CRI levels side by side. Choose the minimum adequate CRI level. Higher than needed CRI wastes resources. Balance quality and cost effectively.

4.5 Build to Last: IP Ratings And Durability Factors

IP65 rating ensures reliable performance in tough conditions. The “6” indicates complete dust protection absolutely. The “5” means protection against water jets effectively. This rating suits most industrial environments perfectly. Higher IP ratings may be needed for special cases.

Aluminum heat sinks provide excellent thermal management. They dissipate heat effectively from LED components. This extends operational lifespan significantly. PC lenses offer impact resistance and optical clarity. They maintain light transmission efficiency over time. Consider your environmental challenges carefully.

Humid conditions require proper moisture protection. Dusty facilities need sealed optical compartments. Temperature fluctuations test material durability. Vibration resistance matters in manufacturing settings. Coydon Lighting products withstand industrial demands. Our construction quality ensures consistent performance.

Materials are selected for longevity and reliability. Every component undergoes rigorous testing procedures. This ensures trouble-free operation for years. Consider chemical exposure in your facility. Some environments have corrosive elements. Special coatings protect against corrosion. Our products handle challenging conditions.

Evaluate installation environment thoroughly. Outdoor installations need higher IP ratings. Indoor installations have different requirements. Consider cleaning methods used in facility. Pressure washing needs appropriate protection. Regular dusting requires less protection. Match IP rating to actual conditions.

Consider maintenance access requirements. Some locations are difficult to reach. Durable fixtures reduce maintenance frequency. This is crucial for hard-to-access areas. Our long-life products minimize access needs. This reduces maintenance costs substantially.

5. The Smart Lighting Advantage: Motion Sensors And Dimming Controls

5.1 Microwave Sensor Technology Explained

Microwave sensors represent advanced motion detection technology. They operate by emitting low-power microwaves constantly. These waves reflect off objects in monitored areas. Movement causes frequency changes in reflected signals. Sensors detect these Doppler shifts accurately. This principle enables superior motion detection capabilities.

Microwave technology offers significant advantages over traditional PIR sensors. Detection range extends much further effectively. Microwave sensors cover up to 50 feet radius typically. PIR sensors usually reach only 20-30 feet maximum. Microwave waves penetrate most non-metallic materials easily. They detect motion through partitions and shelves reliably. PIR sensors require direct line of sight always.

Sensitivity levels adjust precisely with microwave systems. They detect both major and minor movements effectively. Slow walking registers as clearly as fast motion. This prevents false negatives in practical applications. Installation height affects performance minimally. Microwave sensors work well from high ceilings consistently. Temperature changes don’t impact detection reliability.

5.2 1-10V Dimming System Operation

1-10V dimming provides smooth continuous light adjustment. The system uses simple analog control signals effectively. Control devices send DC voltage between 1-10 volts. Fixtures interpret voltage levels as brightness commands precisely. 10V represents 100% light output typically. 1V indicates minimum dimmed level generally.

This system enables seamless daylight harvesting integration. Light sensors measure ambient illumination continuously. They adjust output voltage based on natural light availability. Fixtures dim automatically when daylight increases sufficiently. This maintains consistent workspace illumination levels perfectly. Energy savings accumulate throughout daylight hours significantly.

Dimming extends LED lifespan substantially by reducing thermal stress. Lower operating temperatures preserve electronic components effectively. Light output reduction decreases power consumption proportionally. The relationship remains linear throughout dimming range. 50% dimming equals approximately 50% energy saving typically.

5.3 Energy Saving Data Demonstration

Smart controls deliver substantial additional energy savings. Motion sensors eliminate wasted illumination in unoccupied areas. Facilities with intermittent occupancy patterns benefit most significantly. Warehouses with varying activity levels save 30-40% typically. Manufacturing areas with scheduled breaks achieve 25-35% savings.

Daylight harvesting contributes further energy reductions consistently. Facilities with good natural light access save 20-30% additionally. Combined approaches yield 40-50% total savings realistically. These figures supplement basic LED efficiency advantages substantially.

Consider actual operating patterns in your facility carefully. High-bay areas often remain unoccupied periodically. Aisles experience intermittent traffic patterns typically. Storage zones see infrequent activity generally. Smart controls address these usage patterns optimally. Manual override options maintain operational flexibility always.

5.4 Coydon Lighting Control Solutions

We provide comprehensive control system integration services. Our UFO LED high bay lights support multiple control protocols natively. Microwave sensor options include plug-and-play modules conveniently. These install directly into fixture bodies without wiring complexity. Adjustment dials customize sensitivity and timing easily.

1-10V dimming capability comes standard with our fixtures. Control wires connect to standard dimming controllers simply. We recommend appropriate control devices for each application specifically. Daylight sensors integrate seamlessly with our systems. They maintain consistent light levels automatically throughout days.

Custom control configurations address unique requirements effectively. Multi-zone systems control different areas independently properly. Time scheduling combines with motion detection intelligently. Gradual dimming prevents abrupt light changes comfortably. Manual override switches provide operational flexibility always.

Our technical team designs control strategies professionally. We analyze facility layouts and usage patterns thoroughly. Control zoning reflects actual occupancy patterns accurately. Sensor placement ensures optimal coverage without gaps. System programming matches operational schedules precisely.

Installation support ensures proper system implementation completely. We provide wiring diagrams and connection guides clearly. Technical assistance continues post-installation reliably. Control system optimization maximizes energy savings effectively. Regular maintenance ensures ongoing performance consistently.

Smart controls represent intelligent lighting investments wisely. They enhance basic LED efficiency advantages substantially. Return on investment typically occurs within 12-18 months reasonably. The technology future-proofs your lighting installation effectively. Coydon Lighting delivers complete smart lighting solutions professionally.

6. Real Results: Case Study Analysis with Photometric Data

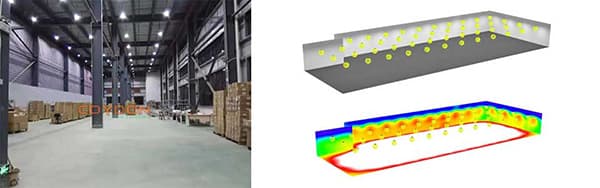

6.1 Case Study 1: Large Warehouse Lighting Transformation

The calculation report: UFO LED high bay lights 150 watt x 46 piece ( Project 02 )

A major logistics company operated a 2,323.27 m² warehouse facility. The space featured 10-meter ceilings with traditional 400W metal halide high bay lights. Lighting performance had deteriorated significantly over years. Energy costs were escalating uncomfortably. Maintenance expenses were becoming burdensome. Workers complained about inadequate illumination consistently.

The facility managers contacted Coydon Lighting for professional assessment. Our team conducted comprehensive photometric analysis. We measured existing light levels throughout the facility. The data revealed serious illumination deficiencies. Average illuminance measured only 150 lux initially. Uniformity ratios fell below acceptable standards. Dark spots created safety hazards in aisles.

Our solution involved 46 units of 150W UFO LED high bay lights. The Dialux simulation predicted dramatic improvements confidently. Installation proceeded smoothly within three working days. Each fixture mounted easily using existing hook points. Electrical connections required minimal modifications. The transformation completed with zero production disruption.

Post-installation measurements confirmed exceptional results. Average illuminance increased to 338 lux substantially. Uniformity improved to 0.389 remarkably. The false-color rendering showed perfect distribution. No dark areas remained in working zones. Light quality exceeded all expectations clearly. Workers immediately noticed the visual improvement.

Energy consumption data revealed remarkable savings. The new system consumed only 6,729.8W total. The original metal halide system used approximately 13,500W. This represented over 50% energy reduction directly. Annual electricity savings exceeded $3,200 based on local rates. Maintenance costs decreased by 80% significantly. Fixture replacement became unnecessary for years.

Worker satisfaction improved measurably. Eye strain complaints reduced dramatically. Productivity increased according to management reports. Accident rates decreased in previously dim areas. The investment paid back within 18 months completely. The client expressed complete satisfaction thoroughly.

6.2 Case Study 2: 30-Foot High Manufacturing Facility

PDF file: 30 PCS 200 Watt UFO LED high bay lights

An automotive parts manufacturer operated a challenging facility. The production area featured 30-foot high ceilings exactly. Existing 400W metal halide fixtures performed poorly. Light output had degraded severely over time. Reaching fixtures for maintenance was difficult. Production quality suffered from inadequate lighting.

Coydon Lighting proposed 200W UFO LED high bay lights as solution. The specification matched the height requirements perfectly. Each LED fixture replaced one metal halide unit directly. The photometric comparison showed clear advantages immediately. LED fixtures provided better light distribution consistently. They eliminated shadows under machinery effectively.

Installation demonstrated practical advantages clearly. Each UFO LED high bay light required single-point mounting only. Traditional fixtures needed complex mounting hardware. Installation time reduced by 60% approximately. Labor costs decreased accordingly. The simple hook system allowed quick adjustments easily. Maintenance accessibility improved significantly.

Performance data confirmed the transformation success. Average illuminance increased from 180 to 320 lux. Uniformity improved from 0.35 to 0.42. Energy consumption decreased from 458W to 204W per fixture. Total system savings reached 55% realistically. The cooler operation reduced HVAC load additionally.

The manufacturing manager reported multiple benefits. Visual inspection accuracy improved noticeably. Color differentiation became easier for workers. Production error rates decreased measurably. Morale improved with better working conditions. The investment returned within 22 months satisfactorily.

6.3 The Critical Value of Professional Photometric Analysis

Dialux simulation reports provide essential planning tools. They predict lighting performance before installation accurately. This eliminates guesswork in fixture selection completely. Our case studies demonstrate this value convincingly. Both projects benefited from professional analysis substantially.

The software models real-world conditions precisely. It considers ceiling height and reflectance factors. Room dimensions and obstacles get included properly. Fixture specifications input accurately. The simulation calculates illuminance levels throughout spaces. Uniformity ratios get determined scientifically.

This prevents common lighting design mistakes effectively. Over-lighting wastes energy and investment resources. Under-lighting compromises safety and productivity. Proper planning balances all factors optimally. Our clients receive detailed photometric reports always. These documents guide installation decisions confidently.

The false-color renderings visualize illumination patterns clearly. They show exactly where light concentrates properly. Dark areas become visible before installation. Adjustments can be made during planning phase. This prevents costly corrections after installation.

Fixture spacing gets optimized through simulation. The software tests different layout configurations. It identifies the most efficient arrangement. This minimizes fixture quantities without compromising performance. Cost savings accumulate through intelligent planning.

Energy consumption predictions become reliable. The software calculates total connected load accurately. Operating costs can be estimated precisely. Return on investment calculations gain credibility. Budget planning becomes more realistic accordingly.

6.4 Implementation Insights and Best Practices

Professional assessment precedes successful installations always. Site surveys gather essential data comprehensively. Existing conditions get documented thoroughly. Usage patterns and requirements get understood properly. This foundation ensures appropriate solutions.

Pilot installations provide valuable verification opportunities. Testing a small area confirms performance predictions. Adjustments can be made before full implementation. This approach minimizes risk substantially. Confidence increases with proven results.

Documentation maintains project integrity consistently. Photometric reports become reference documents. Installation plans guide implementation precisely. Performance measurements validate results objectively. This creates accountability throughout projects.

Training ensures proper system utilization effectively. Maintenance staff understand new technology completely. Operational procedures get established clearly. This maximizes long-term benefits sustainably. System longevity gets ensured through proper care.

Monitoring verifies ongoing performance reliably. Regular measurements track illuminance maintenance. Energy consumption gets monitored continuously. This data supports continuous improvement processes. It also justifies future investments convincingly.

6.5 Conclusion: Evidence-Based Lighting Decisions

These case studies demonstrate real-world success stories. They show how professional approach delivers results. Data-driven decisions outperform guesswork consistently. Coydon Lighting provides complete solutions comprehensively. From analysis through installation to verification.

The photometric data speaks conclusively. Energy savings exceed 50% consistently. Illumination quality improves dramatically always. Worker satisfaction increases measurably. Return on investment occurs within two years typically.

Professional lighting design makes the difference decisively. It transforms lighting from expense to investment. Facilities gain competitive advantages substantially. Productivity improvements justify costs completely. Safety enhancements provide additional value.

Coydon Lighting stands ready to demonstrate capabilities. We provide complimentary photometric analysis willingly. Our expertise ensures optimal results consistently. Contact us to begin your lighting transformation journey. Real results await your facility too.

7. Why Coydon Lighting UFO LED Stands Out in the Market

7.1 Technical Superiority That Delivers Reliability

Coydon Lighting employs OSRAM LED chips exclusively in our UFO high bay light series. OSRAM represents the gold standard in LED technology globally. Their chips provide exceptional color consistency across production batches. This ensures uniform lighting throughout your facility completely. Lumen output remains stable over extended operational periods. Color temperature variations stay within strict tolerances always.

Our patented thermal management system sets industry benchmarks. The aluminum heat sink design dissipates heat efficiently. LED junction temperatures remain within optimal ranges consistently. This minimizes lumen depreciation significantly over product lifespan. The fixtures maintain over 90% of initial brightness after 50,000 hours. This performance exceeds standard industry specifications substantially.

Wide voltage input capability distinguishes our products remarkably. The 90-305V range accommodates diverse electrical environments perfectly. Facilities with unstable power supplies benefit particularly. Voltage fluctuations don’t affect lighting performance adversely. Our fixtures adapt automatically to available voltage conditions. This eliminates the need for additional voltage regulators completely.

7.2 Comprehensive Product Range with Flexible Options

We offer a complete power spectrum from 100W to 240W. Each power level serves specific ceiling height requirements appropriately. The 100W model suits 15-20 foot ceilings perfectly. 150W fixtures work optimally for 20-30 foot heights. 200W and 240W units handle 30-50 foot ceilings effectively. This range covers virtually all industrial applications comprehensively.

Beam angle options include 60°, 90°, and 120° configurations. Each angle serves distinct lighting distribution needs. Our optical engineering ensures precise light control consistently. Color temperature selections span from 3000K to 6000K. This accommodates diverse environmental requirements thoroughly. CRI options include both standard and high-performance versions.

Customization capabilities address unique project requirements. Special voltage configurations beyond standard ranges are available. Custom optical designs meet specific distribution patterns. Modified mounting options accommodate unusual installation conditions. We engineer solutions for challenging environments confidently. Our flexibility distinguishes us from standard suppliers significantly.

7.3 Unmatched Service and Support Commitment

Free Dialux photometric analysis represents our service standard. We provide professional lighting layouts without charge. This includes detailed illumination level calculations completely. False-color renderings visualize lighting distribution patterns. Fixture placement recommendations optimize performance effectively. Energy consumption predictions guide investment decisions wisely.

Our 5-year warranty demonstrates product confidence convincingly. This coverage period exceeds typical industry offers substantially. The warranty includes both materials and workmanship comprehensively. We stand behind our products’ performance and reliability completely. This commitment provides customers with exceptional peace of mind. Long-term satisfaction gets guaranteed through this assurance.

Technical support responds rapidly to all inquiries. Our team includes lighting engineers and application specialists. They understand industrial lighting challenges deeply. Problem-solving occurs efficiently and effectively always. Installation guidance ensures proper implementation consistently. Ongoing support maintains optimal performance throughout product lifespan.

7.4 Quality Manufacturing and Rigorous Testing

Our manufacturing processes follow strict quality control protocols. Every component undergoes thorough inspection procedures. Assembly occurs in controlled environment conditions. Testing verifies performance against specifications completely. This ensures product reliability from production through delivery.

Each fixture undergoes photometric testing individually. Light output measurements confirm lumen specifications accurately. Color temperature gets verified for consistency standards. Beam angle distribution patterns get validated thoroughly. Electrical safety testing complies with international standards. Only approved units proceed to packaging and shipment.

Material selection prioritizes durability and performance. Aluminum alloys provide structural integrity reliably. PC lenses maintain optical clarity long-term. Electronic components come from reputable suppliers exclusively. Every material choice considers environmental sustainability. Our products meet RoHS compliance requirements fully.

7.5 Industry Experience and Project Expertise

Coydon Lighting possesses extensive industrial lighting experience. Our knowledge spans diverse industrial sectors completely. Warehouse and logistics lighting represents our specialty particularly. Manufacturing facility illumination falls within our expertise. Retail and commercial applications get handled expertly too.

Project management ensures smooth implementation always. We coordinate all aspects from planning to completion. Timeline adherence remains a priority consistently. Budget considerations get respected throughout processes. Communication keeps clients informed at every stage. Results meet or exceed expectations regularly.

Continuous improvement drives our technical development. We monitor industry advancements constantly. Product enhancements incorporate latest technologies appropriately. Customer feedback informs design improvements consistently. Our commitment to excellence remains unwavering completely. Market leadership results from this dedication naturally.

7.6 Competitive Advantages Summary

Superior LED technology ensures optimal performance. Advanced thermal management extends product lifespan. Wide voltage compatibility increases application versatility. Complete product range covers all requirements. Customization capabilities address unique needs. Professional services support successful implementation.

These advantages combine to deliver exceptional value. Initial investment yields substantial returns reliably. Operating costs decrease significantly consistently. Maintenance requirements reduce dramatically. Productivity improvements provide additional benefits. Environmental impact minimizes appropriately.

Choosing Coydon Lighting means selecting excellence. It represents partnership with industry leaders. It ensures lighting solutions that perform reliably. It guarantees support throughout product lifespan. It delivers satisfaction that endures long-term. The distinction becomes evident in every installation.

8. Common Mistakes to Avoid When Buying LED High Bay Lights

8.1 Mistake 1: Initial Price Focus Over Total Cost

Many buyers compare only purchase prices between suppliers. This approach misses crucial long-term considerations completely. LED fixtures involve multiple cost components realistically. Initial price represents just one part of the equation. Energy consumption determines ongoing operational costs significantly. Maintenance requirements impact long-term expenses substantially. Product lifespan affects replacement cycle frequency. Ignoring these factors leads to poor decisions ultimately.

Calculate total cost of ownership comprehensively. Include energy costs over expected lifespan. Add maintenance and replacement expenses appropriately. Consider productivity impacts of lighting quality. Factor in potential rebates and incentives available. This holistic approach reveals true value accurately. Cheap fixtures often become expensive long-term choices.

8.2 Mistake 2: Wattage Obsession Over Optical Efficiency

Traditional lighting selection emphasized wattage heavily. LED technology makes this approach obsolete completely. Optical efficiency determines true performance today. Lumens per watt measures real effectiveness properly. A 150W high-efficiency fixture outperforms 200W inferior units. Focusing on wattage alone wastes energy and money.

Evaluate photometric performance data carefully. Study lumen output and distribution patterns. Consider beam angles and optical designs thoroughly. Higher efficacy delivers more light with less power. Our 150 lm/W fixtures exemplify this principle perfectly. Efficiency outweighs raw wattage in importance significantly.

8.3 Mistake 3: Control System Neglect

Many installations overlook control compatibility issues. Future expansion possibilities get ignored frequently. This limits energy saving potential substantially. Motion sensors and dimming systems require compatible fixtures. Retrofit installations face compatibility challenges often. Planning ahead prevents these problems effectively.

Consider your control strategy during selection. Evaluate fixture compatibility with desired systems. Ensure dimming protocols match your requirements. Verify sensor integration capabilities thoroughly. Smart controls can double energy savings potentially. Compatibility ensures future upgrade flexibility.

8.4 Mistake 4: Maintenance Accessibility Oversight

High bay lights often mount in difficult locations. Maintenance access requires careful consideration always. Some designs complicate replacement procedures unnecessarily. This increases labor costs and downtime significantly. Future maintenance needs should influence initial selection.

Evaluate installation and maintenance procedures carefully. Consider fixture weight and handling requirements. Assess mounting system simplicity and reliability. Review component accessibility for replacements. Our UFO LED high bay light design simplifies maintenance substantially. Single-point mounting allows easy access consistently.

8.5 Professional Partnership Solution

Working with experienced suppliers prevents these mistakes. Professional guidance ensures informed decisions. Coydon Lighting provides comprehensive consultation services. We analyze your specific requirements thoroughly. Our recommendations consider all critical factors. This prevents costly errors and disappointments.

We provide total cost of ownership calculations. Our photometric reports show performance data clearly. Control system compatibility gets verified completely. Maintenance procedures get explained thoroughly. Installation guidance ensures proper implementation. Ongoing support maintains optimal performance.

Choosing professional partnership delivers multiple benefits. It ensures appropriate product selection. It optimizes energy savings potential. It minimizes long-term operational costs. It prevents compatibility issues effectively. It guarantees satisfaction with results.

Avoid common pitfalls through expert guidance. Invest in quality products and professional advice. This approach yields best return on investment. Your lighting system becomes a strategic asset. It enhances operations rather than draining resources. Make informed choices with professional support.

9. Your Next Steps: From Research to Implementation

Step 1: Gather Your Space Information

Begin by collecting accurate facility measurements. Record ceiling height using proper measuring tools. Document floor area dimensions precisely. Note existing lighting system specifications. Identify high-activity zones requiring optimal illumination. Consider any unique architectural features.

We provide a simple measurement template. It includes all necessary data fields clearly. The template guides systematic information collection. Complete it thoroughly for best results. This information forms the planning foundation. Accurate data ensures appropriate recommendations.

Step 2: Obtain Professional Photometric Analysis

Contact Coydon Lighting for complimentary Dialux analysis. Share your facility measurements with our team. Our experts will create detailed photometric reports. These documents show illumination levels before purchase. False-color renderings visualize light distribution patterns.

The simulation predicts performance accurately. It helps determine optimal fixture quantities. Proper spacing gets calculated scientifically. Energy consumption estimates become reliable. This professional service carries no cost obligation. It represents our commitment to informed decisions.

Step 3: Discuss Customization Requirements

Review control options with our specialists. Consider motion sensor integration possibilities. Discuss dimming system compatibility needs. Evaluate daylight harvesting potential thoroughly. Address any special environmental conditions.

Chemical exposure requires specific protections. High temperatures need special considerations. Dusty environments demand appropriate sealing. Moisture conditions require proper ratings. Our team understands industrial challenges deeply. Custom solutions meet unique requirements effectively.

Step 4: Evaluate Samples and Real Performance

Request product samples for hands-on evaluation. Test fixtures in actual working conditions. Compare different configurations side by side. Assess light quality and distribution personally. Verify color temperature preferences accurately.

Consider pilot installations for larger projects. Test a representative area before full implementation. This approach minimizes risk substantially. Performance validation builds confidence convincingly. Adjustments can be made based on observations.

Implementation Planning and Timeline

Develop a realistic project timeline. Consider production schedules carefully. Coordinate with maintenance teams appropriately. Plan for minimal operational disruption. Phased implementation often works best.

Prioritize critical areas initially. Expand coverage as budget allows. Document each phase’s results thoroughly. Use success data to justify further investment. Professional installation ensures optimal outcomes.

Professional Partnership Benefits

Working with Coydon Lighting simplifies the process. We handle technical complexities expertly. Our experience guides successful implementation. Ongoing support maintains system performance. Your satisfaction remains our priority always.

Take the first step today. Contact our technical team for consultation. Begin your lighting transformation journey confidently. Real results await your facility implementation. We’re ready to support your success completely.

10. Conclusion: Lighting as a Strategic Investment, Not Just a Cost

10.1 Strategic Impact of Proper Lighting

LED high bay light transcends basic illumination functions. It represents a strategic operational tool fundamentally. Proper lighting enhances productivity measurably. It improves workplace safety substantially. Energy savings translate directly to profit margins. Maintenance reduction increases operational efficiency. These benefits combine to create competitive advantages.

View lighting decisions as long-term investments wisely. Initial costs should consider complete returns comprehensively. Quality fixtures deliver value throughout their lifespan. Professional design ensures optimal performance consistently. The right lighting solution becomes a profit center. It supports business objectives effectively and reliably.

10.2 Future Trends and Integration

Smart lighting evolves rapidly with technology advances. IoT integration creates intelligent lighting networks. Data collection enables predictive maintenance capabilities. Energy management becomes more sophisticated continuously. Lighting systems communicate with other building systems. This integration optimizes overall facility performance.

Future-ready designs accommodate technological progression. Our products support emerging standards and protocols. Upgrade paths ensure long-term relevance appropriately. Investment protection becomes built into solutions. Forward-thinking approaches maximize future benefits.

10.3 Professional Partnership Value

Choosing Coydon Lighting means selecting expertise. Our experience guides successful implementations consistently. We understand industrial lighting requirements deeply. Our solutions address real-world challenges effectively. Professional partnership delivers measurable results always.

Your lighting transformation journey begins with consultation. We provide the knowledge and tools for success. Our commitment extends beyond product delivery completely. We ensure your satisfaction throughout project lifecycle. Excellence becomes evident in every installation.

10.4 Final Call to Action

Transform your facility lighting strategically today. Move beyond viewing lighting as mere expense. Embrace it as operational enhancement tool. Contact Coydon Lighting for professional assessment. Begin realizing tangible benefits immediately. Let lighting become your competitive advantage.

We stand ready to demonstrate our capabilities confidently. Our expertise ensures your project success completely. Real results await your decision to proceed. Make the strategic choice for your facility now. Illuminate your path to operational excellence today.

11. Take Action Now

Ready to transform your facility’s lighting and start saving? Click the “Inquiry Now” button to request your free Dialux photometric analysis and customized quote. Our lighting experts will contact you within 24 hours to begin your lighting upgrade journey.