Light Up Your Understanding: Ditch Wattage Myths, Embrace the Lumen Revolution

For decades, a simple rule dictated lighting choices: higher wattage meant brighter light. This belief, forged in the era of incandescent and metal halide lamps, is now a costly relic. If you’re still selecting high bay lights based on watts alone, you are unquestionably pouring money and energy down the drain. The truth is stark and transformative: a modern 200W LED high bay Light can effortlessly outperform a traditional 400W metal halide high bay light. It delivers superior, crisper brightness while slashing energy consumption by over 50%. The era of wattage as a true brightness indicator is conclusively over.

Welcome to the intelligent age of illumination, where lumens reign supreme. This fundamental shift is not mere technical jargon; it is the essential key to unlocking unprecedented operational savings, enhanced reliability, and superior lighting quality for your warehouse, factory, or gymnasium. Confusion between watts and lumens leads to poor investments and inefficient spaces. At Coydon Lighting, we specialize in cutting through this complexity. We guide industrial and commercial leaders away from these outdated metrics and toward genuinely efficient, high-performance LED lighting solutions engineered for real-world demands and long-term value. Let’s illuminate the critical facts and shed clear light on how to make smart, future-proof decisions for your specific environment. Understanding this difference is the first, most crucial step toward a brighter, more sustainable bottom line.

Part 1: Lumens vs. Watts – What Are They And Why Are They No Longer the Same?

To navigate the modern lighting landscape effectively, we must first dismantle the old paradigm. For over a century, “wattage” was the universal shorthand for brightness. This simple equation, however, has become a dangerous misconception in the age of LED technology, leading to confusion, overspending, and underperformance. Understanding the distinct roles of watts and lumens is not just academic – it’s the financial and operational foundation of any smart lighting upgrade. Let’s break down these critical terms to rebuild your knowledge base on solid, accurate ground.

1.1 Watts (W): The Energy Consumer, Not a Brightness Guarantee

A watt (W) is fundamentally a unit of electrical power. It measures the rate of energy consumption – how much electricity a device uses per second. Think of it like the fuel consumption of a car engine (e.g., liters per 100km). In traditional incandescent bulbs, there was a predictable, linear relationship: a 60W bulb was always brighter than a 40W bulb. This consistency made wattage a convenient, if imprecise, proxy for brightness across decades. This historical accident cemented watts in the public mind as the primary lighting metric.

This relationship completely shatters with LED technology. LEDs are fundamentally more efficient at converting electricity into light. Therefore, wattage now tells you only about a fixture’s appetite for electricity, not its output of light. You can find a 20W LED fixture that is vastly brighter than a 100W incandescent. Choosing based on wattage alone in the LED era is like shopping for a truck based only on its fuel tank size, ignoring its actual hauling capacity. It’s a sure path to either an under-lit space or an unnecessarily high energy bill.

1.2 Lumens (lm): The True Measure of Light Output

This is where lumens (lm) become your most important metric. Lumens measure luminous flux – the total quantity of visible light emitted by a source, as perceived by the human eye. In simple terms, lumens equal brightness. The higher the lumen value, the brighter the light appears. When specifying lighting for a space, your core question should shift from “How many watts?” to “How many lumens do I need on my work surface?”

This focus on output rather than input is revolutionary. It allows for direct, apples-to-apples comparisons between different lighting technologies. Whether it’s an old metal halide, a fluorescent tube, or a modern UFO LED high bay light, if they each produce 20,000 lumens, they deliver the same fundamental amount of light to your space. Lumens provide the objective standard that wattage can no longer offer, putting you firmly in control of your lighting results.

1.3 The Key Breakthrough: Efficacy (lm/W)

Now that we understand watts (input) and lumens (output) separately, we can combine them into the most critical performance metric for modern lighting: luminous efficacy, expressed as lumens per watt (lm/W). This is your lighting efficiency score. It calculates how effectively a fixture converts electrical energy (watts) into visible light (lumens). The formula is simple: Efficacy (lm/W) = Total Lumens / Total Watts.

A higher lm/W rating means more light for less power. For example:

- An old 400W metal halide producing 24,000 lumens has an efficacy of only 60 lm/W.

- A Coydon Lighting 200W UFO high bay light producing 30,000 lumens boasts an efficacy of 150 lm/W.

This single number powerfully links performance to your bottom line. High efficacy (like the 150 lm/W of our lights) directly translates to drastic energy savings, lower utility costs, and a reduced carbon footprint. It is the ultimate quantifier of a lighting product’s technological advancement and economic value, making it the first specification you should check when evaluating any LED high bay light.

Part 2: How to Calculate Your Exact Lumen Requirements

Knowing the theory is one thing; applying it to your unique space is where the real value is unlocked. Determining the correct lumen requirement is a systematic, three-step process that anyone can follow. This section provides the practical, actionable guide to move from concept to a concrete lighting plan. By mastering these steps, you gain the confidence to specify lighting that meets your operational needs without wasting energy or money.

2.1 Step 1: Define Your Space Type And Required Illuminance

The process begins not with lumens, but with Illuminance. Illuminance is the amount of light falling on a surface. It’s measured in foot-candles (fc) in the imperial system or lux (lx) in the metric system (1 fc ≈ 10.76 lx). This is the target brightness level you need at the workplane—typically 0.8 meters (30 inches) above the floor. Different tasks and environments require different levels. Industry bodies like the IES (Illuminating Engineering Society) provide guidelines. Here’s a simplified reference table:

| Application / Space Type | Recommended Illuminance Level |

| Storage Warehouses (bulk, inactive) | 10 – 30 foot-candles |

| General Warehousing (assembly, packing) | 20 – 50 foot-candles |

| Manufacturing / Workshops (detailed tasks) | 50 – 100 foot-candles |

| Gymnasiums / Sports Halls (recreational) | 30 – 50 foot-candles |

| Retail Spaces / Showrooms (merchandising) | 40 – 80 foot-candles |

| Automotive Repair Garages | 50 – 100 foot-candles |

Example: A general storage warehouse might only need 20 fc for safe navigation, while a precision assembly line could require 75 fc for quality control.

2.2 Step 2: Account for Ceiling Height – The Most Critical Variable

Ceiling height dramatically impacts how light travels and spreads. A fixture producing 20,000 lumens mounted at 40 feet will appear much dimmer on the floor than the same fixture mounted at 20 feet. Therefore, after choosing your target illuminance, you must adjust for mounting height. Think of it as needing a more powerful projector for a larger screen. As a general rule of thumb, higher ceilings require fixtures with higher lumen outputs to achieve the same foot-candle level on the work surface.

The following chart provides a starting point for the typical lumen output required per fixture based on mounting height for general industrial/warehouse applications (targeting ~30 fc):

| Mounting Height | Recommended Lumen Output per Fixture |

| 15 – 20 feet (4.5 – 6 m) | 15,000 – 25,000 lumens |

| 20 – 30 feet (6 – 9 m) | 25,000 – 35,000 lumens |

| 30 – 40 feet (9 – 12 m) | 35,000 – 45,000+ lumens |

Crucial Note: Selecting a fixture with too low a lumen output for your height will result in dark, uneven pools of light. Conversely, an overpowered fixture wastes energy and can cause uncomfortable glare. This height-based lumen guide is essential for initial fixture selection.

2.3 Step 3: Apply the Formula to Calculate Total Lumens

Now, you have the two key pieces of information: the brightness needed per square foot (illuminance) and the size of your area. Combine them using this fundamental lighting calculation formula:

Total Lumens Required = Area (in sq. ft.) × Target Illuminance (in foot-candles)

Practical Example: Let’s calculate for a 10,000 sq. ft. warehouse used for general storage and some packing work. We’ll choose a mid-range illuminance target of 25 foot-candles.

- Area: 10,000 sq. ft.

- Target Illuminance: 25 fc

- Calculation: 10,000 sq. ft. × 25 fc = 250,000 Total Lumens Required

This number (250,000 lumens) is the total light output needed to adequately illuminate the entire floor space. The final step is to divide this total by the lumen output of your chosen fixture to determine how many fixtures you need. If you choose a high-efficiency UFO LED high bay light from Coydon Lighting rated at 30,000 lumens, you would need approximately: 250,000 lm / 30,000 lm per fixture = 9 fixtures.

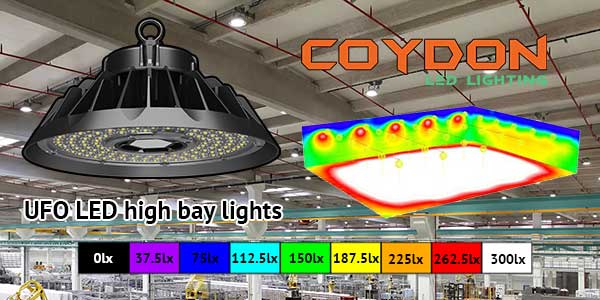

2.4 Professional Upgrade: Why You Need a Dialux Photometric Report

The three-step manual calculation is an excellent starting point. However, real-world spaces are complex. They have aisles, racking, machinery, and walls of varying reflectivity. Manual calculations assume perfect, uniform conditions and cannot account for light distribution patterns, beam angles, or shadowing. This is where guesswork can lead to expensive mistakes – either in over-lighting or creating hazardous dark spots.

A professional Dialux photometric simulation report eliminates all uncertainty. Think of it as a “flight simulator” for your lighting project. Using advanced software, a lighting designer inputs your exact room dimensions, ceiling height, reflectance values, and desired illuminance. They then digitally place specific fixtures (like our Coydon UFO high bay lights) into the model.

The software generates a precise report showing:

- Exact Foot-Candle/Lux Levels: A color-coded floor plan showing illuminance at every point.

- Light Uniformity Ratios: Proving the light is even, without harsh contrasts.

- Fixture Placement And Spacing: The optimal layout to achieve the target with the fewest fixtures.

- 3D Visualizations And False-Color Renderings: See the expected result before purchasing a single light.

This service is not a luxury; it is a standard part of a professional lighting design. At Coydon Lighting, we provide complimentary Dialux photometric analysis for all serious projects. We transform your space data into a clear, actionable plan – like the detailed reports showcased earlier in this article – guaranteeing performance, maximizing savings, and ensuring your complete confidence in the final installation. Don’t leave your lighting to chance; let data and professional design illuminate the perfect solution.

Part 3: Beyond Lumens And Watts – Other Critical Parameters Decoded

While lumens, watts, and efficacy form the performance core, truly exceptional lighting requires a holistic approach. Specifying the right color, distribution, durability, and control transforms a simple illumination task into a strategic asset that enhances productivity, safety, and operational efficiency. At Coydon Lighting, we engineer our UFO LED High Bay Lights with these comprehensive parameters in mind, ensuring they deliver not just light, but the right light for your specific challenge.

3.1 Color Temperature (CCT): Setting the Right Ambiance

Measured in Kelvin (K), Color Correlated Temperature (CCT) describes the visual “warmth” or “coolness” of white light. It’s crucial for creating the desired atmosphere and supporting specific tasks. Unlike brightness, this is a qualitative choice that affects mood and visual clarity.

- 3000K (Warm White): Emits a soft, yellowish light similar to traditional incandescent bulbs. It creates a cozy, relaxed atmosphere. Best for environments where comfort is key, such as restaurant dining areas, hotel lobbies, or premium retail spaces within a larger facility. Our fixtures offer this option for such specialized zones.

- 4500K (Neutral White): Provides a clean, balanced white light. It minimizes eye strain while maintaining good visual acuity and alertness. Best for a wide range of general industrial and commercial applications, offices, and workshops where accurate color perception is moderately important.

- 5000K / 6000K (Cool White / Daylight): Delivers a crisp, bright, bluish-white light that mimics natural midday sun. This spectrum maximizes contrast, sharpens focus, and promotes alertness. Best for warehouses, manufacturing floors, gymnasiums, sports arenas, and any detailed task area (like inspection stations) where high visibility and reduced visual fatigue are paramount. Most Coydon industrial UFO LED high bay lights are optimized for 5000K-6000K to boost productivity.

3.2 Color Rendering Index (CRI): Seeing True Colors

CRI measures a light source’s ability to reveal the true, authentic colors of objects compared to natural sunlight, which has a perfect CRI of 100. A low CRI light can make colors look dull, washed out, or distorted, leading to errors in quality control, product selection, or safety (e.g., misreading wire colors or warning labels).

- CRI 80+ (Good): Suitable for most general industrial and warehouse environments. It provides adequate color distinction for routine tasks, navigation, and general work. All Coydon UFO LED High Bay Lights feature a CRI of 80+, ensuring reliable basic color fidelity.

- CRI 90+ (Excellent): Essential for applications where color accuracy is critical. This includes retail clothing stores, automotive paint shops, art studios, printing facilities, food processing inspection lines, and detailed electronics assembly. For these needs, we offer high-CRI variants to ensure products look their best and defects are easily spotted.

3.3 Beam Angle: Controlling the Shape of Light

The beam angle determines how light is distributed from the fixture. Choosing the correct beam angle is vital for achieving uniform coverage and avoiding dark spots or wasted light.

- 60° Beam Angle (Narrow): Concentrates light into a tighter, more intense circle directly beneath the fixture. Ideal for very high ceilings (over 40 ft / 12 m) or for spotlighting specific areas (e.g., a workbench within a larger space). It ensures light reaches the floor effectively from great heights.

- 90° Beam Angle (Medium/General): The most versatile and common choice. It offers a balanced spread, providing strong central illumination with good peripheral coverage. Ideal for standard warehouse and industrial ceilings between 20-35 ft (6-10.5 m).

- 120° Beam Angle (Wide): Creates a very broad, diffuse light pattern with less peak intensity directly underneath. Ideal for lower mounting heights (15-22 ft / 4.5-6.7 m) or in open areas where maximizing coverage from fewer fixtures is the goal, ensuring seamless blending between adjacent lights.

Coydon UFO LED high bay lights are available in these key beam angles, allowing you to tailor the light distribution precisely to your ceiling height and layout for optimal uniformity and efficiency.

3.4 IP Rating And Build: The Guarantee of Durability

Industrial environments are tough – filled with dust, moisture, vibration, and temperature swings. An IP (Ingress Protection) rating certifies a fixture’s resilience. Our standard rating is IP65.

- ‘6’ (Solid Particle Protection): Dust-tight. No ingress of dust; complete protection against contact. Critical for warehouses where dust accumulation can block optics and cause overheating.

- ‘5’ (Liquid Protection): Protected against low-pressure water jets from any direction. Safeguards against humidity, occasional splashing, and vigorous cleaning. This robust construction, featuring an aluminum housing and high-strength PC lens, ensures our lights withstand harsh conditions for years, minimizing maintenance and replacement costs.

3.5 Smart Controls: Microwave Sensors And 1-10V Dimming

The ultimate step in lighting efficiency moves beyond the fixture itself to intelligent control. Integrating sensors and dimmers can unlock an additional 30-60% in energy savings on top of the inherent efficiency of LED technology.

- Microwave (Radar) Occupancy Sensors: These sensors detect even the slightest motion through walls and obstructions, making them far more reliable than traditional PIR sensors in industrial settings. Lights automatically turn on when an area is occupied and off (or dim to a safety level) after a preset delay when vacant. Perfect for storage aisles, loading bays, and break rooms with intermittent use.

- 1-10V Dimming: This standard protocol allows for smooth, continuous dimming of the light output from 100% down to a minimum level (often 10-20%). It can be paired with daylight sensors to automatically reduce artificial light when ample sunlight is present. It also allows for manual scene-setting – e.g., full brightness for work hours and reduced levels for cleaning or security patrols.

By offering these smart features as configurable options, Coydon Lighting provides a future-proof solution. You can implement a basic, highly efficient system today and easily add sophisticated controls later, continuously driving down your operational costs and enhancing the adaptability of your space.

Part 4: Case Study – How a 200W UFO LED High Bay Light Perfectly Replaces a 400W Metal Halide High Bay Light

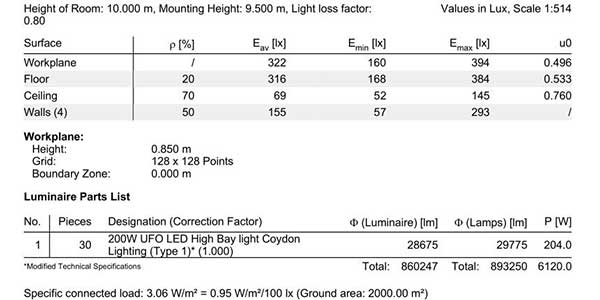

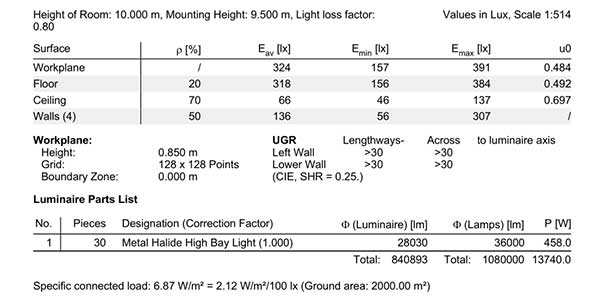

PDF file: 30 PCS 200 Watt UFO LED high bay lights

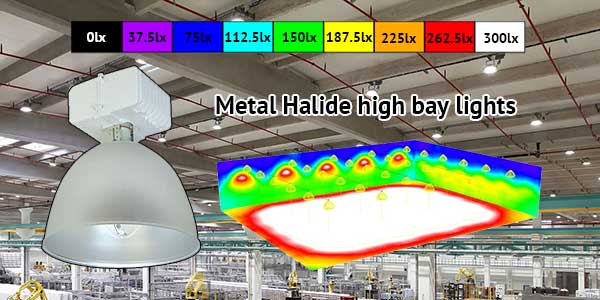

Theory and specifications are compelling, but nothing proves value like a real-world, data-driven comparison. Let’s move from concept to concrete numbers by examining a typical industrial lighting upgrade. We will analyze a side-by-side photometric simulation that provides an undeniable, apples-to-apples comparison between old technology and the Coydon Lighting solution. Prepare to see the dramatic transformation in black and white.

4.1 Scenario Setup: A 2000 sq.m, 10-Meter-High Warehouse

Imagine a standard industrial warehouse, a common challenge for facility managers worldwide. This space measures 50 meters long by 40 meters wide, providing 2000 square meters of floor area. The ceiling height is 10 meters, with a working plane (where light matters most) set at 0.85 meters above the floor. The walls have a standard 50% reflectance, and the space is used for general storage and logistics. The goal is to achieve safe, uniform, and productive illumination across the entire floor.

4.2 The Traditional Baseline: 30 x 400W Metal Halide High Bay Lights

For years, the standard solution for such a space was Metal Halide (MH) technology. In our simulation, this involves installing 30 traditional 400W MH high bay lights, suspended at 9.5 meters and spaced in a regular grid. On paper, this seems adequate. However, the operational reality reveals significant drawbacks that silently drain resources:

- Massive Energy Appetite: Each fixture consumes 458W (including ballast losses), leading to a total connected load of 13,740W.

- Poor Efficiency: Each lamp produces approximately 28,030 lumens, resulting in a low luminous efficacy of only ~61 lm/W. Most energy is wasted as heat.

- Rapid Lumen Depreciation: MH lamps experience severe light loss over time, often dropping to 50-60% of initial output halfway through their lifespan. The space becomes progressively darker.

- Operational Delays: They require a 5-15 minute warm-up period to reach full brightness and cannot restrike immediately if switched off.

- High Heat Output: The fixtures generate intense heat, increasing cooling costs in climate-controlled environments.

- Frequent Maintenance: With a typical lifespan of 10,000-15,000 hours, these lamps require frequent, costly replacements, especially at high mounting heights.

4.3 The Coydon Lighting Solution: 30 x 200W UFO LED High Bay Lights

Now, let’s replace every single 400W MH fixture with a Coydon 200W UFO LED High Bay Light. The number of fixtures (30) and their exact mounting locations remain identical for a perfect retrofit comparison. The results, derived directly from our provided Dialux simulation reports, speak for themselves:

- Dramatically Reduced Consumption: Each Coydon LED fixture uses only 204W, slashing the total system load to 6,120W.

- Superior Light And Efficiency: Each fixture delivers 28,675 lumens, boasting a high efficacy of ~141 lm/W (150 lm/W typical). This means more usable light per watt consumed.

- Instant, Reliable Performance: LEDs provide 100% brightness immediately upon switching on, with no warm-up or restrike delay.

- Exceptional Longevity And Stability: With a rated lifespan of 50,000+ hours and minimal lumen depreciation (L70), the light output remains consistent and bright for years.

- Minimal Heat Emission: LEDs run cool, eliminating added thermal load on HVAC systems.

4.4 The Result: A Transformation in Numbers and Quality

The direct comparison between the two systems in the same simulated space yields a powerful summary of benefits:

| Performance Metric | 30x 400W Metal Halide High Bay Lights | 30x 200W Coydon UFO LED High Bay Lights | Improvement / Saving |

| Total System Power | 13,740 Watts | 6,120 Watts | 55.5% Reduction |

| Average Workplane Illuminance | 324 Lux | 322 Lux | Equivalent Performance |

| Light Uniformity (u0) | 0.484 | 0.496 | More Even Light Spread |

| Estimated Annual Energy Cost | $9,618 | $4,284 | $5,334 Annual Saving |

| Replacement Cycle | Every 1-2 Years | Every 5-10+ Years | ~80% Maintenance Reduction |

| Carbon Footprint | ~61,500 kg CO₂e | ~27,400 kg CO₂e | ~55% Reduction |

Calculation Assumption: 16 hours/day, 6 days/week, 52 weeks/year, at an electricity rate of $0.11/kWh.

Conclusion: This case study proves that upgrading to Coydon’s 200W UFO LED high bay light is not merely a “like-for-like” swap – it’s a massive technological leap. You maintain excellent light levels (even slightly improving uniformity) while cutting your lighting energy bill by more than half. The savings are immediate and substantial, paying for the new system itself in a short timeframe. When you factor in the drastic reduction in maintenance labor, lift rentals, and lamp purchases, the total cost of ownership plummets. This is the undeniable power of choosing the right LED technology: superior light, radical savings, and a smarter, more sustainable operation.

Part 5: How to Select Your Ideal Coydon UFO LED High Bay Light?

Now that you understand the science, the savings, and the superiority of modern LED technology, the final step is translating that knowledge into the perfect product choice for your facility. Selecting the right Coydon UFO High Bay is a simple, three-step process focused on your specific needs. This guide will help you navigate our product range with confidence, ensuring you invest in a solution that delivers maximum performance and return on investment from day one.

5.1 Step 1: Match Power to Your Ceiling Height And Area

The most critical selection factor is your mounting height. Choosing the correct wattage ensures optimal light intensity on your work surface without over- or under-lighting. Based on our high-efficacy design (150 lm/W), here is your straightforward selection guide:

- 100W Model: Engineered for mounting heights between 15-20 feet (4.5 – 6 meters). This is the ideal solution for smaller workshops, loading bays, automotive garages, or specific zones within a larger facility that require focused, efficient illumination.

- 150W Model: The versatile workhorse designed for 20-30 feet (6 – 9 meters). This power range is perfect for the majority of standard warehouses, manufacturing cells, and retail backrooms, providing the ideal balance of wide coverage and high-intensity light.

- 200W And 240W Models: Our high-output champions for 30-50 feet (9 – 15 meters). These fixtures are built for large-scale industrial plants, distribution centers with high ceilings, aircraft hangars, gymnasiums, and sports arenas where powerful, far-reaching illumination is non-negotiable.

Simply measure your ceiling height and refer to this guide to identify your starting point.

5.2 Step 2: Customize Your Smart And Optical Configuration

With your base wattage selected, you can now tailor the fixture to your operational workflow and energy-saving goals. Coydon lights are designed for adaptability.

- Optical Precision (Beam Angle): Specify the beam angle that matches your layout. Choose 60° for high-bay focusing, 90° for standard industrial use, or 120° for wide-area coverage at lower heights. The right angle ensures perfect uniformity.

- Intelligent Control (Add-On Options): Future-proof your investment by opting for integrated microwave occupancy sensors for automatic on/off control in low-traffic areas. Select 1-10V dimmable drivers to enable daylight harvesting or manual light level adjustments. These smart features can drive your energy savings even beyond the base 50-60% reduction.

5.3 Step 3: The Assurance of Quality – Why Choose Coydon Lighting?

Your final decision hinges on trust and proven value. Here is what sets a Coydon solution apart and guarantees your long-term satisfaction:

- Unmatched Efficiency: With industry-leading efficacy of 150 lumens per watt, you are guaranteed the brightest light for the lowest possible energy cost.

- Long-Term Reliability And Warranty: Built with premium OSRAM SMD 2835 LEDs and robust aluminum housings, our fixtures are designed for industrial durability. We back this with a comprehensive 5-Year Warranty for complete peace of mind.

- Professional Support, Not Just a Product: We provide complimentary, professional Dialux photometric design services. Our experts will create a custom lighting layout for your exact space, eliminating guesswork and guaranteeing results before you buy.

- Direct Expert Access: From initial consultation to after-sales support, you work directly with our knowledgeable team dedicated to industrial lighting solutions.

Your path to superior lighting is clear. Identify your required wattage, consider your smart control needs, and partner with a company that provides the technology, the guarantee, and the support to ensure your project’s success.

Conclusion: Act Now to Illuminate Your Efficient Future

The journey from outdated lighting to modern, intelligent illumination is not just possible – it’s imperative for any forward-thinking operation. We’ve dismantled the old myth of wattage, armed you with the critical knowledge of lumens and efficacy, and provided a clear roadmap from calculation to product selection. The data is undeniable, the savings are quantifiable, and the technology is proven. The only question that remains is when you will choose to stop overpaying for light and start investing in performance.

6.1 The Core Takeaway: Forget Watts, Focus on Lumens, Choose Efficacy

Let this be your new mantra. Wattage is a measure of cost; lumens are a measure of result; and efficacy (lm/W) is the powerful link that defines true value. By prioritizing high-efficacy fixtures like Coydon’s 150 lm/W UFO LED High Bay Lights, you directly command brighter, more uniform light for your space while dramatically cutting your energy consumption and operational expenses. This shift in perspective is the single most impactful decision you can make for your facility’s lighting.

6.2 Your Next Step: Claim Your Free Photometric Plan And Custom Quote

Stop wasting money and energy on guesswork! The clearest path to an optimal lighting system is to let our experts handle the details for you. By clicking the “Inquiry Now” button below and providing your basic space information, you will unlock a professional, no-obligation proposal that includes:

- A complimentary, detailed Dialux photometric simulation report for your exact facility.

- Customized product configuration advice tailored to your height, layout, and operational needs.

- A transparent and competitive quotation for your complete project.

Don’t let another month of high utility bills and subpar lighting pass by. Take control of your environment and your budget today. Contact Coydon Lighting now, and let us prove how intelligently designed lighting can transform your space and your bottom line.

100 Watt

KD-HBD-W100-1

Ø248mm X 129mm

150 Watt

KD-HBD-W150-1

Ø295mm X 140mm

200 Watt / 240 Watt

KD-HBD-W200-1 / KD-HBD-W240-1

Ø320mm X 154mm

| Input Voltage: | AC 90V – 305V | |

| Colour Temperature: | 3000K / 4500K / 6000K | |

| Color Rendering Index: | 80+ | |

| LED Type: | LED SMD 2835 ( OSRAM ) | |

| IP Grade: | IP65 | |

| Material: | Aluminium + PC Lens | |

| Luminous Efficiency: | 150 Lumens per watt | |

| Beam Angle: | 60° / 90° / 120° | |

| Warranty: | 5 Years | |

| Mounting Height: | 100 Watt: 15–20 ft (4.5–6 m) 150 Watt: 20–30 ft (6–9 m) 200 Watt: 30–40 ft (9–12 m) 240 Watt: 40–50 ft (12–15 m) |