1. The High Cost of Outdated Lighting

Picture a warehouse manager. She reviews the monthly Profit and Loss Statement. The energy cost line is alarmingly high. On the floor, workers report headaches. The light is dim and uneven. A metal halide bulb just exploded. Maintenance is deploying a lift for replacement. Production in that aisle stops. This is not a rare event. It happens monthly. This is the real cost of outdated lighting.

1.1 A Silent Profit Killer

Your lighting system might be eating your profits. Lighting accounts for 25-40% of industrial energy use. Old lights are energy hogs. They draw far more power than needed. Metal halide and fluorescent lamps are inefficient. They waste electricity as heat. They also degrade quickly. Light output can drop by over 30% in months. You pay for full brightness but receive much less.

1.2 The Maintenance Burden

Legacy lights demand constant care. Their average lifespan is short. Metal halide lasts 6,000 to 15,000 hours. Frequent burn-outs are guaranteed. Replacing them is costly and disruptive. It requires special equipment and labor. It creates safety risks and downtime. Ballasts and starters also fail. This adds more parts and labor costs. The cycle never seems to end.

1.3 Hidden Operational Penalties

Poor lighting has hidden costs. It creates shadows and dark spots. This reduces visibility for workers. It increases the risk of accidents and errors. Eye strain and fatigue lower morale and productivity. Flickering lights are a major distraction. Slow start-up times waste valuable minutes. Inconsistent color rendering affects quality control. These factors directly hurt your operational efficiency.

1.4 The Environmental and Compliance Toll

Outdated lights carry other burdens. Many contain hazardous mercury. Proper disposal is complex and expensive. They generate excessive heat. This increases your building’s cooling load. Their high energy use means a larger carbon footprint. Modern regulations may also phase them out. Staying compliant becomes harder and costlier.

This cycle is clear. High energy use drains finances. Constant maintenance drains resources. Poor light quality drains performance. Together, they form a trap that holds your business back. You need a solution that breaks all these chains at once. The answer is not an incremental fix. It requires a technological leap forward.

That leap is LED High Bay Light. This is not merely a new bulb. It is a complete system upgrade. It directly attacks the core of every problem listed above. It transforms a persistent cost center into a durable source of savings and reliability. The future of industrial lighting is not about replacement. It is about reinvention.

2. Understanding the Lighting Revolution

Lighting is not a minor detail. It is the backbone of industrial and commercial spaces. For decades, facility managers relied on two main technologies. They used metal halide high bay lights and fluorescent lights. These lights served a purpose. However, they come with significant limitations. These limitations are now unacceptable. A revolution has occurred in lighting technology. LED high bay lights are at the forefront of this change. To appreciate the new, we must first understand the old.

2.1 What Are LED High Bay Lights? The Basics of Overhead Illumination

LED High bay light describes lights installed in spaces with high ceilings. These ceilings are typically 15 feet or higher. The primary goal is to deliver bright, uniform light downward. This illuminates large floor areas effectively. Common applications are easy to find. They include warehouses and distribution centers. Manufacturing plants and assembly lines use them. Gymnasiums, sports arenas, and aircraft hangars also rely on them. Even large retail stores require this type of lighting.

For years, two technologies dominated this field. Metal halide high bay lights were the industry standard. They produce light by creating an electric arc through a gas mixture. This mixture includes mercury and metal halides. Fluorescent lights were the other common choice. They generate light by exciting mercury vapor with electricity. This causes a phosphor coating inside the tube to glow. Both systems were considered advanced in their time. They provided more light than old incandescent bulbs. Yet, they operate on fundamentally inefficient principles. These principles lead to high costs and poor performance over time.

2.2 Metal Halide And Fluorescent: Why Are They Now Obsolete?

Metal halide high bay lights and fluorescent lights are legacy technologies. Their flaws are well-documented. They create ongoing operational headaches.

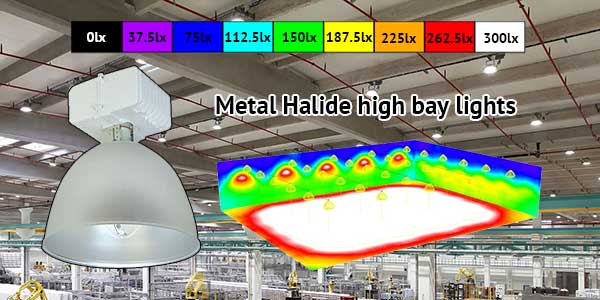

The Case Against Metal Halide High Bay Lights:

Metal halide high bay lights are notoriously inefficient. A typical 400W Metal halide high bay light wastes a huge amount of energy. Much of its power is converted into heat, not light. They have an extremely long warm-up period. They can take 5 to 15 minutes to reach full brightness. If turned off, they require a cool-down period before restarting. Their light output degrades rapidly. It can lose over 40% of its initial lumens within two years. They contain hazardous materials like mercury. This makes disposal complicated and costly. Their omnidirectional light requires large reflectors. Much light is lost inside the fixture itself.

The Case Against Fluorescent Lights:

Fluorescent tubes, like T5HO or T8, are more efficient than MH. However, they are no match for modern LEDs. Their efficiency still falls short. They also contain mercury, posing an environmental hazard. Performance is highly temperature-sensitive. In cold environments, light output and start time suffer greatly. Their lifespan is limited by frequent switching. The ballasts required for operation are another point of failure. They add cost and require maintenance. Light quality is often harsh and can flicker.

Preliminary Comparison Data: Metal Halide High Bay Lights vs. UFO LED High Bay Lights

PDF file: 30 PCS 200 Watt UFO LED high bay lights

The performance gap is immense. Compare a 400W metal halide high bay light directly to its modern LED replacement. The metal halide high bay light system consumes 458 watts of total power. It provides initial bright light. However, this light degrades rapidly. Its useful lifespan is very short. It averages only 15,000 hours of operation. Frequent replacement is a guaranteed cost.

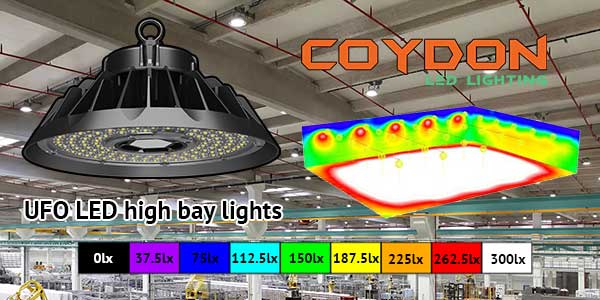

Now, examine the 200W LED high bay light alternative. This light uses less than half the total power. It delivers equal or often superior illumination. The light quality is consistent and does not fade quickly. Its operational lifespan is exceptionally long. It typically lasts between 50,000 and 100,000 hours. This represents a 3x to 6x increase in longevity.

The financial impact is direct and substantial. Energy consumption is more than halved. This slashes the monthly utility bill. The need for bulb replacements nearly disappears. Maintenance labor and downtime are drastically reduced. The total cost of ownership for LED is far lower. The data leaves no room for doubt. Metal halide technology is obsolete.

3. Why LED High Bay Lights Are the Superior Choice

The transition to LED is more than an upgrade. It is a strategic leap forward. This technology delivers across every critical performance metric. It surpasses old lighting in efficiency, longevity, quality, and control. Let’s explore why LED high bay lights are the definitive superior choice.

3.1 Core Advantages: Holistic Performance Beyond Tradition

LED high bay lights represent a fundamental improvement. They excel not in one area, but in all. The first core advantage is exceptional energy efficiency. LEDs convert a high percentage of electricity into visible light. Very little energy is wasted as heat. This direct efficiency slashes power consumption immediately. Operational costs drop from day one.

The second core advantage is extraordinary lifespan. LED lights are designed to last for decades. They do not have filaments or gases that burn out. Their light output diminishes very slowly over time. This longevity eliminates frequent relamping cycles. It dramatically reduces maintenance costs and disruptions. Your facility gains predictable, reliable illumination.

Superior light quality is the third core advantage. LEDs offer excellent color rendering. Colors appear more vivid and true under their light. They provide a range of color temperatures. You can choose warm or cool white light as needed. LED light is also inherently directional. It can be precisely aimed where it is needed. This reduces glare and light spill. It creates a more comfortable and productive visual environment.

The fourth core advantage is unmatched control flexibility. LED technology is digital and solid-state. It integrates seamlessly with modern control systems. This includes dimming, motion sensors, and daylight harvesting. You can adjust light levels based on occupancy or time. This further optimizes energy savings. It also allows for smart building integration. Your lighting becomes an intelligent, responsive asset.

In summary, LED technology provides a complete solution. It combines radical efficiency with unprecedented durability. It pairs brilliant light quality with intelligent controllability. This holistic performance profile is unmatched. It delivers immediate and long-term value. No single feature tells the whole story. The synergy of all these advantages does.

3.2 Energy Efficiency Comparison: Saving Power Saves Money

The energy advantage of LED is not minor. It is transformative. A direct comparison makes this clear. Consider replacing a standard 400W metal halide high bay. It typically consumes 458 watts including ballast loss. A modern 200W UFO LED high bay light can directly replace it. Our Coydon Lighting 200W model uses only 204 watts. It delivers equal or greater light output.

This represents an immediate power reduction. You save 254 watts per fixture. That is over 55% less energy used. The savings compound quickly across a facility. Imagine a warehouse with 100 such fixtures. The total power saving is 25,400 watts. That is 25.4 kilowatts of continuous demand removed.

Real-World Savings Calculation

Let’s translate this into annual cost savings. Assume each fixture operates 12 hours per day. This is common in single-shift operations. Electricity costs $0.12 per kilowatt-hour. The calculation is straightforward. Each LED fixture saves 2.254 kWh daily. Annual savings per fixture reach 823 kWh. For 100 fixtures, annual savings are 82,300 kWh.

The financial result is powerful. This equals $9,876 saved per year. The savings are even greater for 24/7 operations. They can exceed $20,000 annually. This does not include reduced cooling costs. LEDs emit far less heat than metal halide lamps. Your HVAC system works less. This creates additional indirect savings.

The Precision of Professional Analysis

Every facility is unique. Lighting layout and usage patterns vary. Generic calculations provide strong estimates. However, precise planning requires professional tools. Coydon Lighting provides detailed Dialux simulation reports. These reports model your exact space.

They account for ceiling height and reflectivity. They consider specific fixture placement and spacing. The simulation predicts exact illuminance levels. Most importantly, it provides accurate energy consumption forecasts. You receive a clear, data-driven savings projection. This removes all guesswork from your investment decision.

In summary, the energy math is compelling. A 200W UFO LED high bay light directly replaces a 400W metal halide high bay light. It cuts energy use by more than half. The annual savings are substantial and predictable. A professional Dialux report confirms your specific return. This makes the financial case for LED conversion undeniable.

3.3 Longevity and Durability: Less Maintenance, More Uptime

The lifespan of a lighting system matters greatly. It dictates maintenance schedules and costs. Traditional metal halide lamps fail quickly. They average only 15,000 hours of operation. In a facility running 12 hours daily, this means replacement every 3.4 years. Frequent failure is a guaranteed operational burden.

LED high bay lights redefine longevity. Our fixtures offer a rated life of 50,000 to 100,000 hours. This is 3 to 6 times longer than metal halide. In the same 12-hour daily operation, an LED lasts 11 to 22 years. The difference is not incremental. It is transformative for facility management.

Built to Last: The Durability Advantage

Long life stems from robust design. LED technology has no fragile filaments. There is no glass envelope to break. Our Coydon UFO LED high bay lights use durable materials. The housing is high-grade aluminum. This ensures excellent heat dissipation. It also provides strong impact resistance.

The fixtures carry an IP65 rating. This means they are dust-tight. They are also protected against water jets. This durability suits harsh industrial environments. There are no toxic materials like mercury inside. This eliminates hazardous disposal concerns. The solid-state design withstands vibration. It is ideal for facilities with heavy machinery.

The Real Cost of Maintenance

Maintenance costs extend far beyond bulb prices. Replacing a metal halide lamp is complex. It often requires a scissor lift or boom lift. This involves rental costs and operator labor. The process creates safety risks. It also causes significant downtime. Production in the area must often stop.

These costs multiply with frequent replacements. A single lift rental can exceed $300 per day. Technician labor adds more expense. Lost productivity is another major cost. This cycle repeats every few years for metal halide. It becomes a predictable drain on resources.

LED technology slashes these costs dramatically. The multi-year lifespan eliminates most replacements. No special lifting equipment is routinely needed. Maintenance labor is reduced to occasional cleaning. There is no production disruption for relamping. This provides continuous operational uptime.

The financial impact is substantial. Consider a facility with high ceilings. It may avoid 3 to 5 full replacement cycles over 15 years. This saves thousands in lift rentals and labor. It prevents countless hours of lost productivity. The reliability of LED lighting is a strategic asset. It ensures your operations run smoothly without interruption.

3.4 Light Quality and Visual Comfort: Brighter, More Uniform, Safer

Light quality directly impacts performance. It affects worker safety and accuracy. It influences overall productivity. Traditional lighting often fails in this area. Metal halide high bay light degrades and shifts color. Fluorescent lighting can flicker and hum. LED technology solves these issues completely. It delivers superior visual performance.

Color Accuracy and Adaptability

True color rendering is crucial. Our Coydon LED high bay lights feature a CRI over 80. This is a high Color Rendering Index. It means colors appear vibrant and accurate. Details are sharp and clear under this light. This is vital for quality control tasks. It helps in identifying parts and materials. It improves overall visual clarity.

We offer three color temperature options. You can choose 3000K, 4500K, or 6000K. Warm 3000K light is calming and inviting. It suits retail areas or break rooms. Neutral 4500K light is balanced and natural. It is ideal for general warehouse work. Cool 6000K light is crisp and energizing. It is perfect for detailed assembly tasks. This flexibility adapts light to your needs.

Visual Comfort and Operational Performance

Flicker-free light is essential for comfort. Our LEDs provide steady, constant illumination. There is no visible flicker or strobing. This reduces eye strain and headaches. Workers feel less fatigue over long shifts. Instant start-up is another key benefit. The lights reach full brightness immediately. There is no warm-up delay required.

Directional lighting offers major advantages. LEDs emit light in a specific pattern. Our fixtures use precise optics. They focus light downward onto the work area. This minimizes wasted upward light. It also reduces glare for workers. The light goes exactly where it is needed.

This directional control cuts light pollution. It prevents stray light from spilling out. This is important for facilities with shift work. It helps maintain dark skies at night. Uniform light distribution is also achieved. There are no dark spots or bright hotspots. The entire floor receives even illumination.

Safety and Precision Enhancement

Better light means a safer workplace. Hazards are more visible and identifiable. Shadows that hide trip points are reduced. Accurate color rendering aids in safety labeling. Warning signs appear clearer and brighter. This contributes directly to accident prevention.

The cumulative effect is significant. Workers perform tasks with greater ease. They make fewer errors due to poor visibility. Morale improves in a well-lit environment. Operational efficiency rises as a result. The investment in quality light pays dividends daily. It creates a superior working environment for all.

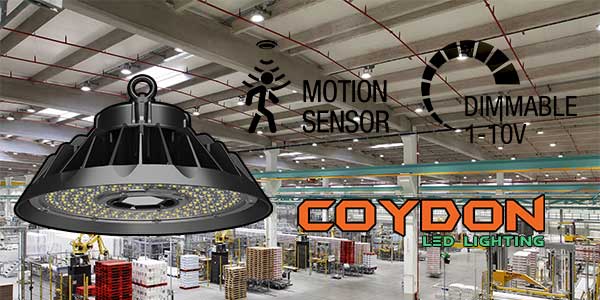

3.5 Smart Control and Future-Ready Design

Modern lighting does more than illuminate. It interacts intelligently with its environment. LED technology enables this capability perfectly. Our Coydon high bay lights offer advanced control features. These include microwave sensors and 1-10V dimming. This transforms lighting from a static cost into a dynamic asset.

Advanced Control Capabilities

Microwave sensor technology is highly effective. It detects even subtle motion through materials. This is ideal for dusty or cluttered warehouses. The sensor can trigger lights automatically. They turn on when someone enters an area. They turn off after the area is vacant. This eliminates wasted energy in unused spaces.

1-10V dimming provides precise light level control. You can adjust brightness manually or automatically. This is perfect for areas with variable tasks. It also works with daylight harvesting systems. Lights dim when natural light is sufficient. This saves energy without sacrificing visibility. The combination of these tools is powerful.

Seamless System Integration

Our fixtures are designed for easy integration. They connect smoothly with building management systems. This includes modern BMS and IoT platforms. You can create centralized lighting control. Schedules and settings are managed from one point. Real-time monitoring is also possible. You see energy use and fixture status instantly.

Integration supports advanced strategies. Lights can be grouped into zones. Each zone has its own control logic. This allows for granular energy management. It also enables scenario-based lighting. Different light levels suit different activities. The system adapts to your operational rhythms.

Additional Energy Savings from Controls

Smart controls deliver substantial extra savings. Consider a storage area with sporadic use. Traditional lights might stay on for 12 hours. With occupancy sensors, usage drops drastically. Lights may only operate 2 hours daily. This saves over 80% of lighting energy there.

Daylight harvesting adds more savings. Perimeter areas near windows benefit most. Lights dim automatically on sunny days. This can cut energy use by 20-40%. Dimming also extends fixture lifespan. It reduces thermal stress on LED components. This further lowers long-term maintenance costs.

The cumulative impact is significant. Smart controls can reduce total lighting energy by 30-50%. This is on top of the inherent LED efficiency. The payback period for controls is often short. They future-proof your lighting investment. Your system remains adaptable and efficient for years.

Adopting smart controls is a strategic decision. It maximizes the return on your LED upgrade. It also creates a more responsive work environment. Your facility operates with greater intelligence and economy. This is the true potential of modern high bay lighting.

4. Make the Switch with Coydon Lighting

Your lighting upgrade is a critical investment. The right partner determines its success. Technical specifications matter greatly. Reliable support and service matter more. Coydon Lighting is a proven leader in both areas. We offer a complete solution for your facility. Our approach combines superior products with dedicated partnership. We ensure your project achieves all its goals.

4.1 Why Choose Coydon Lighting?

Our product performance is outstanding. We achieve 150 lumens per watt efficiency. This industry-leading figure maximizes energy savings. We use premium OSRAM LED components. This ensures consistent color and long life. Our fixtures are built with durable materials. They withstand demanding industrial environments. A strong 5-year warranty protects your investment fully. This reflects our confidence in quality.

Our service begins with expert planning. We provide free professional Dialux simulations. This creates an optimized lighting layout for your space. We develop custom solutions for unique challenges. Our team supports you through the entire process. We help with specification and installation planning. Ongoing technical support is always available. We are a true partner for your success.

Our company commitment is clear. We deliver exceptional quality and reliability. Your operational success is our primary goal. We help reduce costs and improve safety. We enhance productivity through better lighting. Choose Coydon Lighting for a superior result. Let us build a brighter future for your facility together.

4.2 How to Start Your Lighting Upgrade Project?

Beginning your upgrade is simple and risk-free. We guide you through a clear three-step process. This ensures a smooth transition to superior lighting. Our structured approach minimizes disruption to your operations. You gain full visibility at each stage.

Step 1: Contact Us for a Free Dialux Report.

Reach out to our lighting specialists today. Share basic details about your facility. We analyze your current layout and needs. Our team creates a detailed Dialux simulation report. This free report shows your new lighting plan. It includes precise illuminance levels and energy savings.

Step 2: Custom Design and Quotation.

We present the optimized lighting layout. We discuss any specific requirements you have. Our experts tailor the final solution for you. You receive a comprehensive project quotation. It includes all products and service costs. The proposal is clear with no hidden fees.

Step 3: Professional Installation and Support.

Our certified partners handle the installation. They ensure a fast and tidy process. Your operations experience minimal downtime. We provide thorough post-installation support. This includes system verification and staff training. Our team remains available for future assistance.

4.3 Act Now, Illuminate Your Future!

The perfect time for action is today. Energy costs continue rising globally. This trend increases your operational expenses monthly. Utility rebates and incentive programs are available now. However, these financial benefits have limited funding. They often expire without warning. Delaying your decision has a real cost.

Secure your savings and advantages immediately. Click the “Inquiry Now” button on our website. This starts your free, no-obligation consultation. Our lighting experts will contact you promptly. We will discuss your specific project needs. You will receive your personalized Dialux report quickly.

We commit to a rapid and responsive process. You will get a detailed reply within 24 hours. Our team is ready to help you move forward. Do not let this opportunity for savings pass by. Transform your lighting and your bottom line today. Contact Coydon Lighting now for a brighter tomorrow.

5. Conclusion: Illuminate an Efficient, Safe, and Sustainable Future

The industrial lighting revolution is here. LED high bay lights are now the undisputed standard. This transition is driven by powerful, undeniable forces. Economic pressure demands lower operating costs. Environmental responsibility requires sustainable choices. Operational excellence needs reliable, high-quality illumination. The move away from outdated metal halide and fluorescent systems is not just advisable – it is essential for competitive, future-ready businesses. Continuing with legacy lighting means accepting unnecessary costs, risks, and limitations.

Choosing Coydon Lighting as your partner ensures a successful transition. We offer more than superior products with industry-leading 150 lumens-per-watt efficiency and robust 5-year warranties. We provide a comprehensive partnership built on expertise and commitment. Our free Dialux simulation delivers a precise, data-backed roadmap for your project. Our customized solutions address your facility’s unique challenges. Our dedicated support guides you from initial consultation through installation and beyond. We stand behind every project with a promise of quality, reliability, and your ultimate success.

Do not let obsolete technology constrain your business growth. Outdated lighting silently drains profitability and impedes safety and morale. Upgrading to Coydon LED high bay lights is a direct investment in operational superiority. It delivers immediate and long-term returns through radical energy savings, eliminated maintenance burdens, and enhanced productivity. The time for analysis is over; the time for action is now. Seize this opportunity to transform a core operational element into a source of lasting advantage.

Reach out to Coydon Lighting today to start your journey. Click ‘Inquiry Now’ for your free, no-obligation consultation and Dialux report. Our experts will contact you within 24 hours to map out your brighter, more efficient, and more profitable future. Illuminate your path forward. Let’s build it together.