Did you know that outdated high bay lights can waste up to 40% of energy while leaving dark corners in your warehouse? A 60m×24m factory slashed its annual electricity bill by $2578 simply by switching to 24 UFO LED lights. If your facility still uses metal halide or fluorescent lamps, you’re paying for inefficiency.

But the problem isn’t just energy waste. Poor lighting impacts productivity and safety. A study by the U.S. Department of Energy found that optimized LED lighting reduced workplace errors by 30% and accident rates by 25%. Imagine what this could mean for your assembly lines or inventory management.

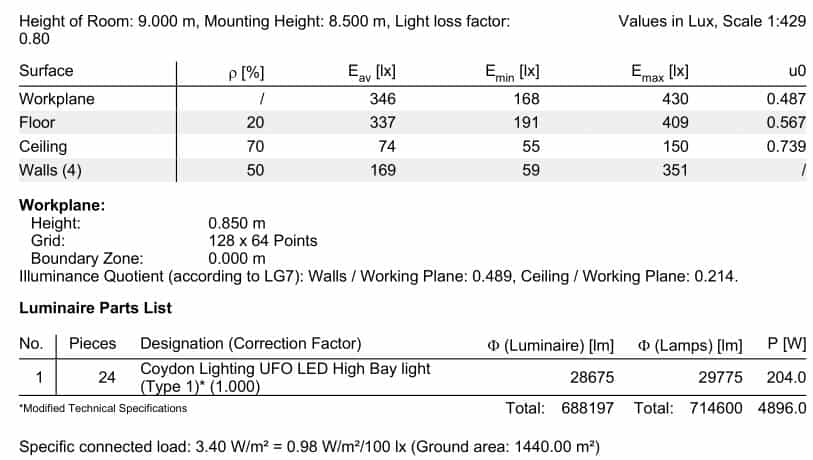

The magic number 150Lm/W means every watt of electricity converts to bright, uniform light. For example, a 150W UFO LED (like the KD-HBD-W150-1) delivers 28675 lumens – enough to illuminate a 50㎡ area at 500 lux. Paired with a 120° beam angle, it eliminates shadows even in 9m-high facilities.

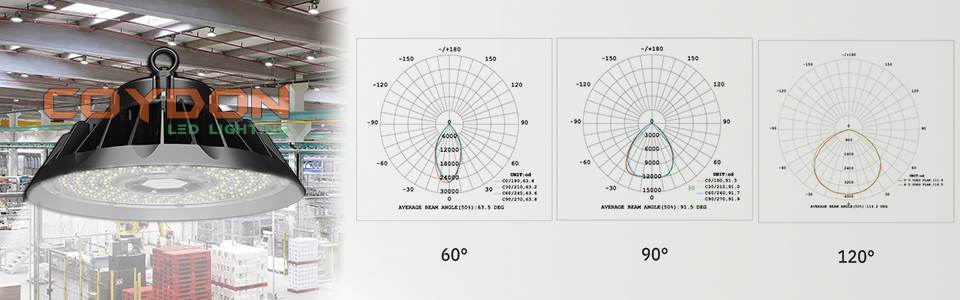

But how does beam angle affect your layout?

- 60°: Ideal for tall racks (12m+) needing focused light.

- 90°: Balanced coverage for aisles and machinery.

- 120°: Best for open spaces like warehouses.

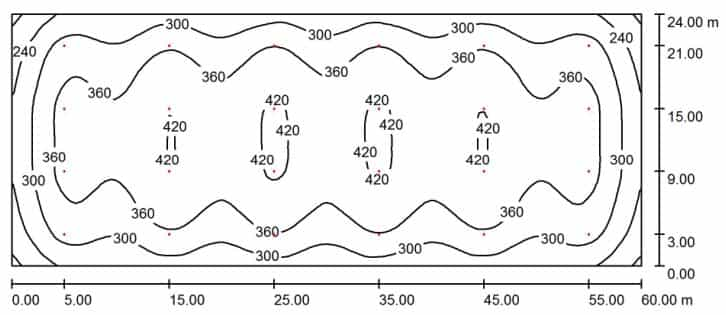

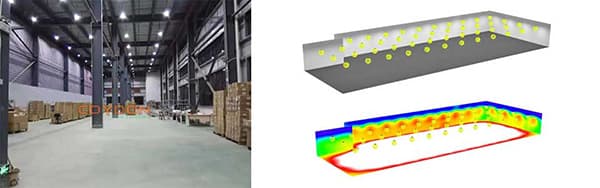

How 24 Lights Transformed a 1440㎡ Warehouse

In a real case from the Dialux report, 24 UFO LED high bays achieved:

- 346 lux average illuminance on workplanes (meeting industrial standards).

- $0.98 energy cost per m²/100 lux—3x cheaper than traditional lighting.

- Zero maintenance for 5 years thanks to IP65-rated durability.

Get a Custom Plan in 3 Clicks

- Step 1: Tell Us Your Space

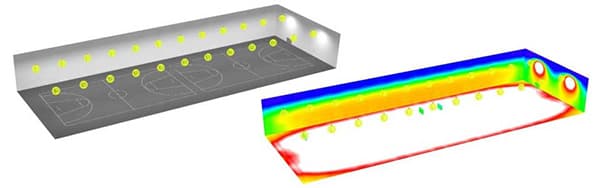

Just share your room dimensions and desired brightness (e.g., 300/500/800 lux). No need to understand lumens or beam angles – we handle the rest. - Step 2: Receive a Free 3D Lighting Simulation

Within 24 hours, our engineers will send you:

A Dialux-generated light distribution map showing no dark zones.

Energy savings forecast (e.g., “Save $2500/year”).

Installation blueprint with mounting heights and spacing. - Step 3: One-Click Order and 5-Year Support

Approved the plan? We ship globally with installation guides. Plus, enjoy lifetime technical consultations.

Beyond Lighting: Sustainability and Smart Controls

Modern UFO LED high bays aren’t just about brightness – they’re part of a smarter ecosystem:

- Motion Sensors: Lights dim to 20% when no activity is detected, saving an extra 15% energy.

- DALI Controls: Adjust groups of lights via a central system for shift-based lighting.

- Solar Integration: Pair with rooftop panels for net-zero energy consumption.

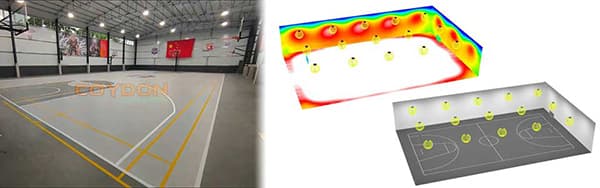

Project 01: Professional Lighting Solution for Outdoor Basketball Court

Project 02: High-Efficiency LED Warehouse Lighting System – 338 Lux Uniformity

Project 03: Outdoor Basketball Court Lighting Solution

FAQs: Answering Your Top Concerns

Q: How long does installation take?

A: Most projects finish in 2-3 days. We provide labeled cables and step-by-step videos.

Q: Can I reuse existing electrical lines?

A: Yes! UFO LEDs use 50% less power, so existing infrastructure is often sufficient.

Q: What if my facility has irregular shapes?

A: Our Dialux simulations account for pillars, mezzanines, and uneven ceilings.

Conclusion: Lighting Should Be Simple – Let Us Prove It

Why waste time on complex formulas when experts can deliver a turnkey solution? Click below to upload your floor plan, and get a free lighting design + sample report today.

Why Choose Us?

✅ Zero Risk: Free design with no obligation.

✅ Proven results: reducing costs and increasing efficiency for more than 100 customers over the years.

✅ Carbon Neutral Partners: We offset emissions from shipping and manufacturing.

🔍 Limited Offer: First 50 inquiries get a FREE Dialux template!

Don’t hesitate, click “Inquiry Now” to contact us.