1. Introduction: Revolutionizing Industrial Lighting with Unmatched Stability

Picture this scene: during a critical late-night shift, a massive industrial warehouse continues its relentless operation. Forklifts rumble through the aisles, workers meticulously assemble precision components – the entire workflow hinges on one fundamental element: stable, high-quality lighting. The moment this lighting falters, productivity plummets, safety risks multiply, and operational errors proliferate. Now, imagine the overhead fixtures beginning to flicker without clear cause.

This is no minor inconvenience, but a symptom of a profound systemic flaw. Voltage fluctuations, triggered by the cycling on and off of heavy machinery, persistently undermine the stability of traditional lighting systems. Aging metal halide fixtures exacerbate the issue: they are notorious for their staggering energy consumption, inefficient heat dissipation, and demand for frequent bulb replacements coupled with exorbitant maintenance costs. Every flicker of light translates to wasted energy, unnecessary expenditure, and a dual threat to both corporate profitability and worker safety.

This persistent challenge, plaguing factories, distribution centers, and logistics hubs worldwide, now meets its definitive solution. Coydon Lighting’s newly launched KD Series UFO LED High Bay Light is engineered precisely to eradicate these chronic issues. At the heart of its revolutionary design lies the 90V-305V ultra-wide voltage input technology. This groundbreaking feature guarantees consistently stable, flicker-free illumination, completely immune to grid voltage fluctuations. As the ultimate solution in industrial lighting, it not only ensures exceptional performance but also significantly reduces operational costs, infusing your operations with dependable lighting power – finally enabling a decisive break from the limitations of the traditional industrial lighting era.

2. The High Cost of Sticking with Traditional Lighting

Continuing to operate with traditional metal halide lighting represents a significant and unnecessary financial burden for modern industrial facilities. The conventional 400W metal halide high bay fixture exemplifies this problem through its numerous operational deficiencies.

2.1. Five Critical Deficiencies of Metal Halide Technology

- Extreme Energy Inefficiency: These lamps convert most electrical energy into heat rather than visible light. This wasted energy not only increases electricity consumption but also creates additional cooling costs for the facility.

- Rapid Lumen Depreciation: Metal halide lamps lose more than 50% of their initial light output long before complete failure. This progressive dimming creates increasingly darker work environments that compromise both safety and operational precision.

- Extended Warm-Up Requirements: Each activation requires 10-15 minutes to reach full illumination intensity. This delay disrupts workflow continuity and consumes energy without providing usable light during the warm-up period.

- Voltage Sensitivity Issues: The performance of these lamps is highly susceptible to power fluctuations. This sensitivity leads to unpredictable performance and premature failures, requiring unscheduled maintenance interventions.

- Frequent Maintenance Demands: The combination of these deficiencies results in frequent lamp replacements and consistent maintenance attention. This drives up operational costs through both replacement parts and dedicated labor hours.

2.2. The Compelling LED Alternative

Modern LED technology presents a dramatically superior solution. The comparison is striking: a single 200W KD UFO LED High Bay Light effectively replaces a 400W traditional metal halide fixture while delivering equivalent or superior illumination. This direct replacement immediately reduces energy consumption by over 50% while eliminating all characteristic weaknesses of metal halide lighting.

The transition to LED technology represents more than just a lamp replacement – it constitutes a strategic operational upgrade. Facilities benefit from instant illumination, consistent light output throughout the lifespan, immunity to voltage fluctuations, and dramatically reduced maintenance requirements. The long-term financial advantages become increasingly evident through sustained energy savings and eliminated replacement cycles.

3. Deep Dive: Engineering Excellence of the KD Series

The Coydon KD Series represents a fundamental re-engineering of industrial lighting principles. Every component is precision-engineered to deliver exceptional performance that directly addresses modern facilities’ most pressing challenges. This technical excellence translates into tangible operational benefits across five key dimensions.

3.1. Conquer Voltage Fluctuations: The 90V-305V AC Advantage

Industrial facilities face constant power quality challenges that conventional lighting cannot handle. Voltage drops during equipment startup and spikes during shutdown create visible flickering in traditional fixtures. The KD Series eliminates this problem completely through its revolutionary 90V-305V ultra-wide voltage input capability. This advanced electrical design automatically compensates for grid instability, maintaining perfect illumination consistency regardless of power fluctuations. The technology proves particularly valuable in regions with underdeveloped electrical infrastructure and facilities operating heavy machinery. Manufacturing plants with large motors and welding equipment benefit from this unprecedented stability. The wide voltage range also simplifies global procurement and logistics, allowing companies to standardize on a single product for all international operations without concern for local grid variations.

3.2. Superior Light Quality and Efficiency: 150 LPW and Beyond

The KD Series achieves an exceptional 150 lumens per watt (LPW) efficacy through advanced optical and thermal engineering. This measurement indicates how effectively electricity converts into visible light, with higher values representing better performance. At 150 LPW, the fixtures produce significantly more illumination per watt than conventional alternatives while consuming substantially less energy. This high-efficiency performance comes from premium OSRAM SMD 2835 LEDs, renowned for their consistent light output and extended operational lifespan. These professional-grade components deliver a Color Rendering Index (CRI) of 80+, ensuring colors appear natural and accurate rather than washed out or distorted. This superior color quality reduces eye strain during detailed inspection tasks and improves overall visual comfort. The combination of high efficacy and quality components creates a lighting solution that maintains excellent performance throughout its extended service life.

3.3. Built to Last: Robust IP65 Aluminum and PC Construction

Industrial environments present some of the most demanding conditions for lighting fixtures. The KD Series meets these challenges through its rugged IP65-rated construction that provides complete protection against environmental contaminants. The high-grade aluminum housing serves dual purposes, offering exceptional durability while functioning as an efficient heat dissipation system. This thermal management is crucial for maintaining LED performance and longevity, as it prevents the temperature buildup that causes premature light degradation. The polycarbonate lens adds another layer of protection with its exceptional impact resistance and optical clarity. This material combination ensures reliable operation in environments containing dust, moisture, and accidental impacts. Food processing facilities, agricultural operations, and manufacturing plants with washdown requirements particularly benefit from this robust construction. The fixtures withstand conditions that would quickly degrade lesser lighting products.

3.4. Customizable Lighting: Beam Angles and CCT for Every Scenario

Different industrial applications require specifically tailored lighting characteristics for optimal performance. The KD Series addresses this need through multiple beam angle and color temperature options. The available 60°, 90°, and 120° beam angles enable precise light distribution matching for various ceiling heights and layout configurations. High-bay storage facilities over 40 feet typically benefit from the concentrated 60° beam that delivers maximum light to the floor level. Standard manufacturing areas with 20-30 foot ceilings achieve ideal coverage with the versatile 90° option. Lower-ceilinged spaces like workshops and assembly areas receive uniform illumination from the widespread 120° distribution. The available color temperatures (3000K, 4500K, 6000K) further enhance application-specific optimization. Warm 3000K creates a comfortable atmosphere in break areas, neutral 4500K provides balanced illumination for general manufacturing, while cool 6000K promotes alertness in high-precision work zones.

3.5. Smart and Responsive: Microwave Sensor and 1-10V Dimming

Modern industrial lighting must provide not just illumination but intelligent control capabilities. The KD Series offers integrated microwave sensor technology and 1-10V dimming interfaces for sophisticated energy management. The microwave motion detection system offers significant advantages over traditional infrared sensors, detecting movement through non-metallic materials and around obstacles with superior reliability. This capability enables automatic lighting activation in occupied areas and power reduction in vacant spaces, creating substantial energy savings in low-traffic zones. The 1-10V dimming capability allows seamless integration with building management systems for programmed lighting control. Facilities can implement daylight harvesting strategies that automatically adjust artificial light levels based on available natural light. This dual approach of occupancy-based control and continuous dimming capability typically reduces lighting energy consumption by an additional 30-50% beyond the inherent efficiency of LED technology, delivering a rapid return on investment while maintaining optimal lighting conditions.

4. Case Study: Proof in Performance - A 2323 m² Warehouse Transformation

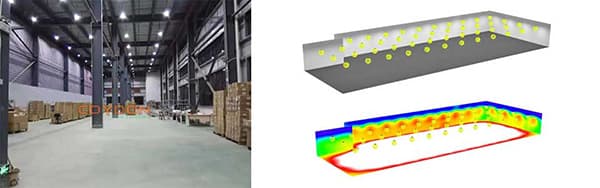

The calculation report: UFO LED high bay lights 150 watt x 46 piece ( Project 02 )

Theoretical claims about lighting performance are easily made. But nothing proves value like documented results from real-world conditions. Through advanced Dialux simulation software, we can demonstrate exactly how the KD Series transforms industrial spaces, using a 2,323 square meter warehouse as our living laboratory.

4.1. Project Overview: A Modern Warehouse Challenge

This case study examines a typical distribution warehouse with an 8-meter ceiling height. The operational requirements demanded consistent, high-quality illumination across the entire space to ensure safety, accuracy in order picking, and efficient workflow. The lighting needed to overcome the space’s scale while maintaining energy efficiency. The solution deployed was 46 units of the 150W Coydon KD UFO LED High Bay Lights, strategically positioned for optimal coverage.

4.2. Quantifiable Results: Exceeding Industrial Standards

The post-installation simulation data reveals exceptional performance across all critical metrics. The lighting system achieved an average illuminance of 338 lux on the work plane (0.85 meters high). This level not only meets but exceeds the requirements for most industrial tasks like packing, sorting, and machinery operation. More importantly, the lighting distribution is exceptionally even. The uniformity (U0) of 0.389 signifies the absence of dark spots and sharp contrasts. This minimizes eye fatigue for workers scanning shelves and reading labels, directly enhancing both comfort and productivity throughout long shifts.

4.3. Efficiency and Economic Impact

The energy performance is equally remarkable. The total system consumes only 6,729.8 watts to illuminate the vast 2,323 m² area. This translates to an exceptionally low connected load of 2.90 W/m². For comparison, a traditional metal halide system providing similar light levels would typically require over 12,000 watts. This represents an immediate energy reduction of over 50%, leading to a drastic cut in electricity costs. The project’s specific connected load of 0.86 W/m² per 100 lux establishes a new benchmark for efficient industrial lighting design, proving that high light levels do not require high energy consumption.

4.4. Scientifically Validated Performance

These are not estimates; they are scientifically verified outcomes. Every data point comes from a professional Dialux simulation, the industry-standard software for lighting design. This provides irrefutable, third-party validation that the KD Series will perform as predicted in your facility. It removes the guesswork from lighting upgrades, offering a guaranteed outcome before any physical installation begins. This case study moves beyond promises, providing concrete evidence that the KD Series delivers superior illumination, outstanding energy savings, and a rapid return on investment.

5. Beyond the Warehouse: Versatile Applications

While the warehouse case study demonstrates clear success, the Coydon KD Series’ capabilities extend far beyond storage facilities. Its robust engineering and flexible specifications make it the ideal lighting solution for numerous demanding environments. Each setting benefits from the fixture’s core advantages: exceptional energy efficiency, unwavering reliability, and superior light quality.

In manufacturing workshops and assembly lines, the high Color Rendering Index (CRI 80+) ensures accurate color discrimination. Workers can identify components and spot defects with greater ease and precision. The durable IP65 construction withstands airborne particles from machining and material handling. For sports halls and gymnasiums, the combination of high luminous efficacy and flicker-free illumination is crucial. It provides bright, consistent light for fast-moving activities while eliminating the strobe effect that can strain athletes’ vision. The availability of different beam angles allows for optimal court illumination.

Parking garages and outdoor canopies benefit immensely from the KD Series’ wide voltage input and robust housing. The fixtures deliver reliable performance despite temperature variations and voltage fluctuations common in such semi-outdoor settings. The optional microwave sensor drastically reduces energy consumption during low-traffic periods. In cold storage and food processing facilities, the lights perform flawlessly in low-temperature and high-humidity conditions. The IP65 rating provides essential protection against moisture and corrosion, ensuring operational safety and longevity. Across all these diverse applications, the KD Series proves to be a versatile, high-performance lighting solution that enhances visibility, safety, and efficiency.

6. Why Partner with Coydon Lighting?

Choosing Coydon Lighting means more than purchasing products. You gain a reliable partner committed to your long-term success. Our comprehensive support system ensures your lighting project delivers outstanding results from concept to completion and beyond.

6.1. Confidence Through Warranty Protection

We stand firmly behind the quality and durability of our products. The 5-Year Comprehensive Warranty on the KD Series provides you with complete peace of mind. This extensive coverage reflects our confidence in the materials and workmanship. It protects your investment against manufacturing defects, ensuring uninterrupted performance. This long-term commitment significantly reduces your long-term operational risks and costs. You can install our lighting solutions with absolute confidence in their reliability.

6.2. Risk-Free Planning with Professional Simulation

We eliminate the guesswork from your lighting upgrade. Our complimentary Dialux simulation service provides a scientifically accurate preview of your project’s outcome. Our experts create a detailed model of your space using industry-standard software. You will see the exact illumination levels, uniformity, and energy consumption before installation. This data-driven approach guarantees the proposed solution will meet your specific requirements. It enables perfect planning and prevents costly post-installation modifications, ensuring a zero-risk decision for your business.

6.3. Unmatched Expertise and Customer Support

Our relationship begins with your inquiry and continues throughout the product lifecycle. Coydon’s dedicated technical support team possesses deep knowledge of industrial lighting applications. They are ready to assist you with layout planning, product selection, and technical specifications. We provide practical solutions tailored to your unique challenges and budget. Our goal is to ensure you achieve optimal lighting performance and maximum value from your investment. Partner with us for a seamless experience from initial consultation to long-term satisfaction.

7. Take Action: Illuminate Your Space with Confidence

The evidence is clear and compelling. The Coydon KD Series delivers what matters most in industrial lighting: voltage stability for uninterrupted operation, exceptional energy efficiency that slashes costs, professionally validated performance you can trust, and smart, flexible control for modern needs. This combination translates directly into lower operating expenses, enhanced safety, and a rapid return on your investment.

Stop overpaying for outdated, inefficient lighting. Do not let another month pass with high electricity bills and maintenance headaches draining your resources. You have seen the proven results. Now is the time to experience them in your own facility.

Taking the first step is simple and carries no obligation. Click the “Inquiry Now” button today. You will receive a prompt and free quotation tailored to your project. More importantly, you can request your complimentary, customized Dialux simulation report. This personalized report will visually demonstrate the exact lighting performance and energy savings the KD Series can achieve in your specific space. Make the decision to illuminate with confidence and step into a brighter, more efficient future.

8. Conclusion: Smarter Light for a Smoother Operation

Upgrading to the Coydon KD Series is more than a simple lighting change. It is a strategic decision for operational excellence. You are choosing guaranteed stability against power fluctuations, proven energy efficiency for cost reduction, and future-ready intelligent controls. This investment creates a more reliable, productive, and sustainable working environment.

The path to superior illumination is clear. The technology is proven, the savings are quantifiable, and the support from Coydon Lighting is unwavering. Do not let inertia maintain the status quo of high costs and mediocre performance. Take that decisive first step today. Transform your facility with lighting that works as hard as your business does. Embrace the smarter light that powers smoother operations and a brighter bottom line.